- Accueil

- Ressources

- CNC Machining Invar: Processes, Advantages, Finishing

CNC Machining Invar: Processes, Advantages, Finishing

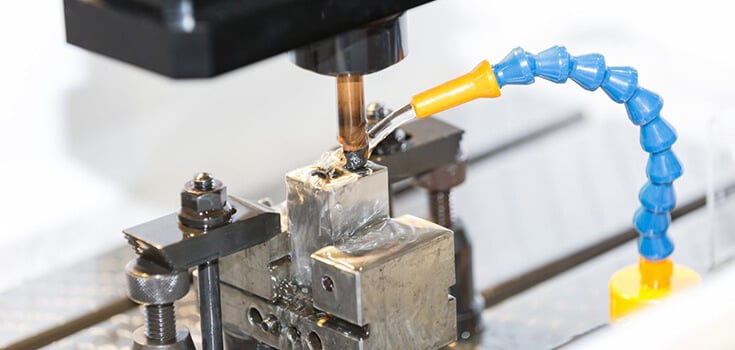

When I handle CNC machining Invar, my goal is to achieve accuracy that does not shift with temperature. Invar’s steady nature lets me create parts that keep their exact shape no matter the heat or cold. It is the material I choose for projects that demand high consistency and reliability.

CNC machining makes it easy for me to create complex Invar parts with smooth details and dependable tolerances. Whether it’s aerospace tooling or measuring devices, every piece stays consistent.

What is CNC Machining Invar?

CNC machining Invar involves using computer-controlled machines to cut, drill, and shape Invar alloy to precise parts. Invar is a nickel-iron alloy famous for its very low thermal expansion, allowing me to create parts that stay dimensionally stable even under temperature changes.

Because of its accuracy and consistency, CNC-machined Invar is commonly used in aerospace, optical, and electronic applications, industries that demand long-term stability and flawless performance.

Material Properties of Invar

| Catégorie | Type / Element | Percentage / Value |

| Composition | Nickel (Ni) | 36% |

| Fer (Fe) | 64% | |

| Cobalt (Co) | 5–6% (optional in Super-Invar) | |

| Selenium (Se) | Trace (in Free-Cut grades) | |

| Main Characteristics | Coefficient de dilatation thermique | ~1.2 ppm/°C |

| Densité | 8.1 g/cm³ | |

| Point de fusion | ~1,427 °C | |

| Résistance à la traction | 450–590 MPa | |

| Magnetic Properties | Ferromagnetic | |

| Variants | Standard Invar 36 | — |

| Free-Cut Invar 36 | — | |

| Super-Invar | — | |

| Kovar | — |

CNC Machining Invar Processes

3-axis to 5-axis Milling

When I machine Invar using 3-axis to 5-axis milling, I rely on rotary cutting tools to remove material with extreme precision. Because Invar tends to harden during cutting, I always choose my tools, speeds, and feeds carefully. Multi-axis milling lets me create complex geometries and maintain tolerances as tight as ±0.005.

Perçage CNC

For CNC drilling, I use sharp carbide or high-speed steel drills to make precise holes in Invar parts. Lubrication and controlled feed rates to reduce friction and prevent tool wear. This technique is perfect for creating fastener holes, mounting points, and precise alignment features.

Tournage CNC

During CNC turning, I rotate the workpiece while the cutting tool stays fixed. Because of Invar’s low thermal conductivity, I ensure to apply proper cooling during machining to prevent heat buildup and surface damage.

Swiss Machining

In this process, the material passes through a small guide bushing that keeps it stable. This setup helps minimize vibration and produce tiny, delicate parts.

Usinage par décharge électrique (EDM)

This process allows me to create fine details, tight internal corners, and complicated shapes by removing material using controlled electric sparks. Both sink and électroérosion à fil help me reach exceptional precision for optical and aerospace parts that demand intricate designs and flawless accuracy.

Advantages of CNC Machining Invar

High Dimensional Accuracy

Invar’s low thermal expansion allows me to maintain precise measurements, even when parts are exposed to temperature changes or thermal stress.

Repeatable Quality

I can produce identical parts with consistent precision and surface finish from batch to batch.

Excellent Customization

Usinage CNC gives me full control to adjust shapes, holes, threads, or surface features according to project requirements.

Supports Complex Geometries

I can produce detailed and intricate components with multi-axis machining.

Corrosion and Wear Resistance

Invar’s natural durability allows finished parts to handle harsh environments and maintain integrity over time.

Improved Production Efficiency

Free-cut Invar grades help me reduce machining strength and stability.

Reliable Weldability

Invar can be welded and repaired without losing dimensional accuracy.

Surface Finishes for CNC-Machined Invar Parts

As-Machined

When parts are used directly after CNC machining, I refer to them as as-machined. These components may show light tool marks or surface texture from the cutting process. While they are not mirror-smooth, they are perfectly suitable for internal assemblies.

Broyage

I apply precision broyage for applications that need very high levels of accuracy and smooth surfaces. This process relies on an abrasive wheel to remove small amounts of material, achieving tight tolerances and a smooth, flat finish.

Électropolissage

It is an electrochemical process that removes a thin surface layer to create a clean, bright, and corrosion-resistant finish. I use it when components must be free of contamination and easy to sterilize, such as in vacuum chambers, instrumentation, or cleanroom assemblies.

Polissage

When a smooth or reflective appearance is required, I perform mechanical polishing using fine abrasives and compounds. This process minimizes surface roughness and enhances reflectivity.

Sablage de perles

For components that need a matte, non-reflective surface, I use bead blasting. This technique propels fine spherical media onto the surface to create a consistent, satin-like texture. It is a great choice for aesthetic parts or assemblies.

Applications of Invar Machined Parts

Électronique

I use CNC-machined Invar for semiconductor frames and test fixtures. These parts must stay perfectly stable as the equipment heats up and cools down, and slight movement can cause misalignment.

Optical Equipment

Its ability to hold shape under changing conditions keeps lenses and mirrors in perfect alignment, ideal for instruments like microscopes, telescopes, and laser devices.

Aérospatiale

Invar 36 is one of the few alloys I trust for parts that face both extreme heat and cold. I’ve seen it used in optical benches, satellite frames, antenna supports, and navigation systems. It prevents signal errors and structural distortion in orbit.

Dispositifs médicaux

I use invar in MRI machines because it helps maintain the magnetic field alignment needed for clear imaging. It is also great for surgical tools and precision instruments. Its non-magnetic nature and reliability make it a safe and trusted material in a medical environment.

Conclusion

CNC machining Invar gives me the precision, stability, and strength I need for demanding projects. No matter the temperature or pressure, every Invar part I produce holds its shape and performs exactly as intended, making it one of the most reliable materials I’ve used.

If you are looking for high-precision Invar CNC machining, partner with DEK. Our skilled team delivers tight-tolerance Invar components with the speed, accuracy, and quality your project deserves. Contactez nous today to get started.

FAQ

Is Invar difficult to machine?

Machining Invar can be tricky because it is tough and work-hardens easily. I use sharp carbide or high-speed steel tools, slow cutting speed, and steady feeds to keep accuracy and prevent tool wear.

Quelle est la différence entre l'Inconel et l'Invar ?

Invar is an iron-nickel alloy with low thermal expansion, ideal for precision parts. Inconel, a nickel-chromium alloy, is made for high heat and corrosion resistance.

What grade of Invar is commonly used for CNC machining?

Invar 36 is the most common grade for CNC machining because of its near-zero thermal expansion. When it comes to machining Invar 36, I get a perfect balance of stability, strength, and machinability.