Aerospace Sheet Metal Fabrication Service

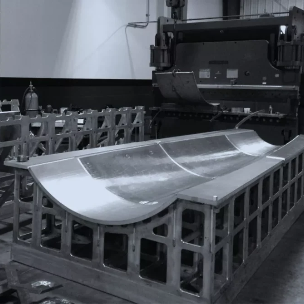

Aerospace sheet metal fabrication uses cutting, bending, and forming to make precise, lightweight parts that need tight tolerances and flight standards for strength and safety.

DEK offers custom sheet metal fabrication for all types of aircraft. We make complex parts for commercial, military, and private aircraft. From titanium skins to aluminum supports, we handle demanding jobs with speed and accuracy. Every part is inspected to meet strict aerospace requirements and built to handle pressure, heat, and motion.

introduction

Aerospace Sheet Metal Fabrication | Built to Spec, Built to Last

DEK makes aerospace sheet metal parts to your exact specs. We use fast service, advanced machines, and certified materials to support your toughest builds.

We provide full-service aerospace sheet metal fabrication designed for strength, accuracy, and repeatability. Every part is built to spec and made to last under real flight conditions. We use advanced tools like laser cutters, CNC punch presses, press brakes, and welding systems to shape certified materials—aluminum, titanium, stainless steel, and aerospace-grade alloys. From skins and brackets to enclosures and frames, your parts are cut, formed, and assembled with care. We also offer DFM support, rapid prototyping, surface finishing, and final assembly—all under one roof. In-process inspections and CMM checks ensure every part performs under pressure, heat, and motion.

Whether you need one part or full production, DEK delivers fast turnaround, consistent quality, and responsive support from start to finish.

- In-process inspections

- Flight-ready quality

- Custom tooling and jigs

- One-stop service

- Full DFM support

- Prototypage rapide

Matériaux for Aerospace Sheet Metal Fabrication

Métaux

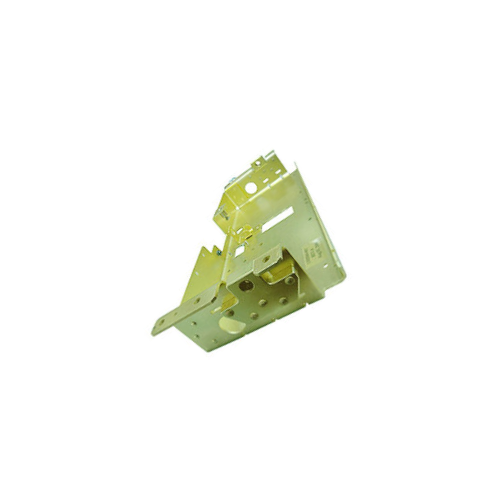

Acier allié

Alloy steel offers exceptional strength, toughness, and weldability, making it perfect for aerospace sheet metal fabrication of structural supports, tubing, and mechanical assemblies.

DEK fabricates precision parts like struts, hydraulic line brackets, and reinforcement ribs with exacting quality and tight tolerances. Our experienced team uses advanced forming, welding, and finishing processes to ensure these components meet stringent aerospace requirements for durability and resilience. You get reliable, high-performance parts designed to withstand heavy loads and demanding operating conditions.

Alliages

4140, 4340, AISI 4130, 8620

Aluminium

Aluminum offers exceptional lightness and natural corrosion resistance, making it a top choice in aerospace sheet metal fabrication for skins, fuselage panels, and structural frames. Its excellent formability allows precise bending and shaping to tight tolerances.

DEK’s advanced fabrication techniques ensure smooth finishes and consistent quality for parts like wing skins, bulkheads, and cargo floor panels. Whether for prototypes or production runs, we deliver components that meet strict aerospace strength and weight standards, helping you build efficient and reliable aircraft.

Alliages

2024, 6061, 7075, 5052

Inconel

Inconel’s exceptional heat and corrosion resistance make it key for aerospace sheet metal fabrication in engine components, heat shields, and turbine blades.

DEK precisely fabricates parts such as exhaust manifolds, combustion chamber liners, and nozzle guide vanes. Our skilled processes maintain Inconel’s integrity under extreme temperatures and stress. The components we produce support engine reliability, durability, and performance, enabling aerospace systems to operate safely and efficiently in the harshest environments.

Alliages

Inconel 718, Inconel 625, Inconel 600

Magnésium

Magnesium’s lightweight properties suit aerospace sheet metal fabrication for parts where weight reduction is critical, including instrument housings, interior panels, and seat frames.

DEK handles magnesium carefully to produce components like avionics enclosures, cockpit panels, and structural brackets. Our fabrication processes ensure these parts meet aerospace standards for strength and dimensional accuracy while contributing to overall aircraft weight savings. Magnesium’s use helps improve fuel efficiency and performance by reducing aircraft mass without sacrificing durability.

Alliages

AZ31B, AZ61A, etc.

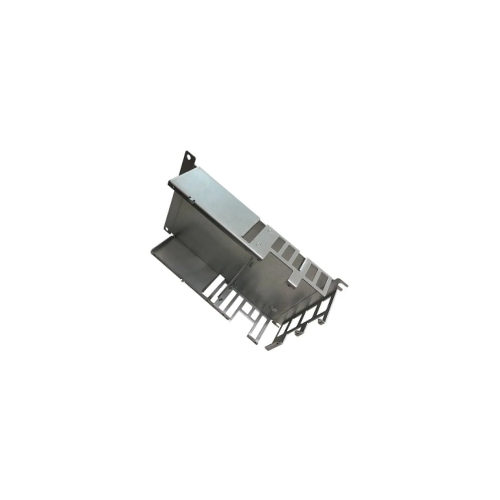

Acier inoxydable

Stainless steel is a reliable choice in aerospace sheet metal fabrication for parts requiring strength and corrosion resistance, such as exhaust ducts, fasteners, and mounting brackets.

DEK ensures precise forming and finishing to meet aerospace specifications. Our expertise supports manufacturing heat shields, fuel line supports, and bracket assemblies that withstand harsh environments, temperature changes, and mechanical stress. We provide durable, long-lasting components essential for aircraft safety, structural integrity, and operational reliability.

Alliages

304, 316, 321, 17-4 PH

Acier à outils

Tool steel is essential in aerospace sheet metal fabrication for tooling, dies, and precision fixtures.

DEK creates components like press dies, forming tools, and precision jigs that maintain hardness, wear resistance, and dimensional stability. Our fabrication supports aerospace production by delivering durable tools designed for accuracy and repeatability. These tools help maintain tight manufacturing tolerances and quality control, ensuring consistent part production and smooth assembly processes critical to efficient aerospace manufacturing operations.

Alliages

A2, D2, O1, H13

Titane

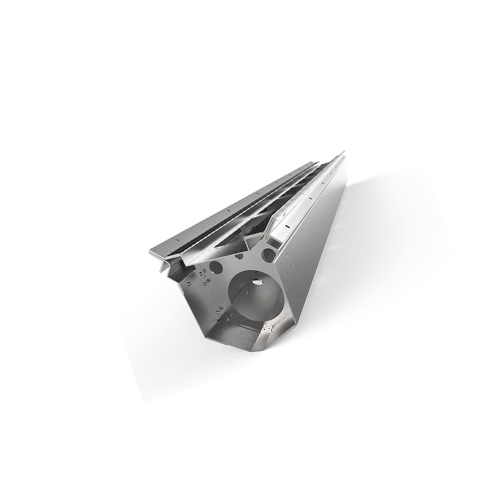

Titanium’s high strength-to-weight ratio and corrosion resistance make it ideal for aerospace sheet metal fabrication of engine components, structural supports, and landing gear parts.

DEK expertly handles titanium’s toughness, producing parts like engine mounts, actuator brackets, and fuselage frames with tight tolerances. Our precision fabrication maintains durability and heat resistance critical for aerospace applications, supporting your need for lightweight, robust components that endure extreme conditions and enhance aircraft safety and performance.

Alliages

Grade 5 (Ti-6Al-4V)

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Nos avantages

2300+ ingénieurs Aimer travailler avec nous

Tolérances serrées

At DEK, every aerospace part is fabricated with tight tolerances, down to ±0.005 mm, ensuring critical fit, performance, and reliability. Our advanced cutting, forming, and measuring equipment allows us to meet demanding aerospace specs.

Aerospace Grade Materials

We work only with certified aerospace-grade materials. All materials are fully traceable and sourced to meet aerospace compliance standards. This guarantees consistent performance in high-pressure, high-heat environments.

Géométries complexes

DEK handles complex part designs using advanced equipment and smart processes. We use CNC punching, laser cutting, press braking, and custom jigs to form multi-angled parts, tight bends, and compound curves. Our skilled team brings your challenging geometries to life.

Une production rentable

With DEK, you get high-quality aerospace parts without inflated costs. We streamline setup times, minimize rework with in-process inspections, and reduce waste with efficient nesting and cutting strategies. We help you stay on budget while still meeting tight aerospace specs.

Advanced Surface Finishing

We offer a full range of aerospace-compatible finishes, including anodizing, passivation, powder coating, sandblasting, and polishing. All finishing work is handled in-house to ensure full control over quality and lead time.

Normes de qualité certifiées

DEK operates under AS9100D-certified quality systems and other aerospace requirements, giving you full confidence in every aerospace part we deliver. Every project includes detailed inspections, process controls, and CMM verification to guarantee accuracy and reliability.

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.

Envoyer l'appel d'offres 222

Revue et citation

Confirmer la commande

Production

QC

Livraison

FAQ

Aerospace Sheet Metal Fabrication FAQ sur l'achat

Obtenir un devis précis Pour vos prochains projets

Que votre projet soit simple ou compliqué, qu'il s'agisse de métal ou de plastique, vous obtiendrez un devis précis dans les 6 heures.

Obtenir un devis aujourd'huiSavoir Aerospace Sheet Metal Fabrication

What is Aerospace Sheet Metal Fabrication?

Aerospace sheet metal fabrication is the process of cutting, bending, and forming thin metal sheets into parts used in aircraft. These parts include panels, brackets, frames, and skins. The process uses specialized tools to meet tight tolerances and aerospace-grade standards, ensuring parts are lightweight, strong, and ready for flight.

In addition to shaping parts, this process also includes finishing steps like deburring, riveting, and surface treatment to prevent corrosion and wear, ensuring long-lasting performance under extreme flight conditions.

What are the Advantages of Aerospace Sheet Metal Fabrication?

This fabrication process supports complex designs and uses certified materials to meet strict requirements for safety and performance. Benefits include:

- Lightweight, high-strength components

- Haute précision et tolérances serrées

- Compatibility with aluminum, titanium, and more

- Quick turnaround for prototyping and production

- Reduced material waste and cost-efficiency

- Reliable quality for critical flight parts

When Do You Need Aerospace Sheet Metal Fabrication?

Use aerospace sheet metal fabrication when building or repairing aircraft components that must handle pressure, vibration, and heat. It is ideal for commercial, military, and private aircraft, including UAVs. You need aerospace fabrication when accuracy, weight savings, and structural performance are critical to your part’s success in flight.

It’s also the right choice when your design involves complex geometries, tight timelines, or certified materials. Whether you’re working on early-stage prototyping or ready-to-fly assemblies, aerospace fabrication helps ensure every part fits perfectly and performs dependably in demanding flight environments.