- Accueil

- Ressources

- 5 Common Mistakes to Avoid When Machining an Actuator Housing

5 Common Mistakes to Avoid When Machining an Actuator Housing

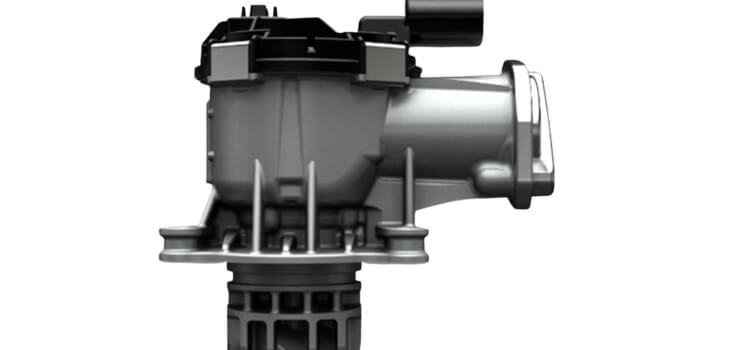

Machining an actuator housing may seem simple, but you must consider critical factors to produce a high-quality product. In the aerospace industry and other precision-driven fields, even the slightest error can cause significant issues.

In this blog post, we'll uncover five common mistakes encountered when machining an actuator housing and provide valuable tips on how to avoid them.

By understanding these pitfalls and applying our expert advice, you can enhance your manufacturing process, save time and money, and ultimately deliver superior customer results.

Common Mistakes To Avoid When Machining An Actuator Housing

Inaccurate Measurements

One of the most common mistakes when machining an actuator housing is inaccurate measurements. This can happen for various reasons, including using faulty measuring tools or not taking precise readings.

However, even the slightest variation in size can have significant consequences when producing a high-quality product. For instance, the actuator may fail and require expensive repairs or replacement if internal components do not fit correctly due to incorrect measurements.

It's essential to use high-quality measuring tools and double-check all calculations before machining. In addition, it's crucial to ensure that all team members involved in the manufacturing process communicate clearly about specifications and tolerances to prevent any misinterpretations that could result in errors.

Finally, ongoing training on correctly measuring and interpreting data should be provided so everyone involved is skilled at accurate measurement techniques.

Poor Material Selection

When machining an actuator housing, one of the most critical mistakes many manufacturers make is choosing low-quality materials.

The aerospace industry requires high-grade materials that can withstand extreme conditions and provide optimal performance for extended periods. Selecting subpar material can lead to product failure, reduced durability, and expensive repairs.

It's essential to understand the material properties required for each component while ensuring that cutting tools match their characteristics.

Using quality raw materials will help produce reliable products with higher mechanical tolerances over longer service life cycles while improving production efficiency by reducing tool wear rates during Usinage CNC.

Incorrect Machining Techniques

As someone in the machining industry for years, I can tell you that incorrect machining techniques are one of the biggest mistakes to avoid when working on an actuator housing.

This includes using the wrong type of cutting tools or machine settings, making erroneous cuts, or improperly setting up fixtures.

One time I saw a machinist use a lathe to cut threads into an actuator housing without properly calibrating the turret beforehand. The result was a part with inaccurate thread measurements that could only be fixed by scrapping it and starting over.

Therefore, it's crucial to always follow CNC programming instructions and double-check all tooling setups before beginning any work on your part.

In short, taking shortcuts when it comes to proper machining techniques will only lead to wasted effort and resources in the long run.

Instead, ensure you're investing enough time upfront in providing accurate manufacturing methods so you don't have to go back through unnecessary troubleshooting later.

Lack Of Lubrication

Without proper lubrication, the cutting tools and equipment can wear out quickly, causing defects in your product. I learned this lesson early on in my career after failing to apply sufficient oil to a lathe during a turning operation, damaging the material and tooling.

To prevent such errors from happening, always ensure you use high-quality lubricants that are appropriate for the materials you're working with. Choosing a quality coolant or oil will significantly reduce friction levels between parts and ensure precise tolerances.

Additionally, regular maintenance checks and inspections should detect any irregularities caused by insufficient cooling or inadequate lubrication before they become major problems that impact production efficiency.

Improper Assembly

Even if you've followed all the proper machining techniques, a simple error during assembly can lead to defects and costly production delays. I once witnessed a machinist forgetting to verify that all screws were correctly tightened, causing the actuator housing to fail during testing.

It's essential to take care during assembly and double-check everything before proceeding. Ensure all parts are aligned correctly, and any necessary fasteners or connectors are tightened.

Take your time and don't rush through this step, as it can make the difference between a successful product launch or significant downtime due to excessive rework.

Tips For Avoiding These Mistakes

Use High-Quality Materials

Using high-quality materials in machining an actuator housing ensures that the final product performs optimally and lasts longer. Therefore, when selecting materials for actuator housing, it's essential to consider their properties, such as strength, durability, heat resistance, and corrosion resistance.

For instance, steel alloys can provide excellent strength and durability, while alliages d'aluminium offer exceptional corrosion resistance.

High-quality materials also enable manufacturers to produce parts with tight tolerances required for actuator housing components. This is to ensure the actuator system's proper fit and function.

Conversely, using poor quality or substandard materials may result in defects during production or cause premature failure of the final product after installation.

Double-Check Measurements

Here are some tips for double-checking your measurements to avoid costly mistakes:

- Use a calibrated measuring tool

- Measure multiple times

- Verify against specifications

- Check for tolerances

- Have a colleague check your work

Follow Machining Procedures Carefully

One mistake can lead to expensive rework or, even worse - scrapped parts. To avoid this, you must pay attention to every step of the machining process and ensure you follow the correct procedures.

For example, inputting the correct codes and specifications into the machine is crucial when setting up a CNC machine for an actuator housing job. Otherwise, you may end up with a part that doesn't meet requirements or won't fit properly in assembly.

Additionally, taking the time upfront to check your tooling and fixtures can prevent errors from occurring during production runs.

Another aspect of carefully following machining procedures is ensuring proper communication between team members involved in production.

Clear documentation and effective troubleshooting allow everyone on the team to stay informed about any issues during machining operations. By doing so, you'll catch errors before they become bigger problems.

Ensure Proper Lubrication

Here are some tips for providing proper lubrication:

- Use the Right Lubricant

- Apply Lubricant Correctly

- Don't Mix Lubricants

- Use Clean Lubricants

- Perform Regular Maintenance

Take Care During Assembly

One of the most critical stages in machining an actuator housing is during assembly. At this point, all the parts come together to form a complete unit- and any mistakes could render all previous efforts irrelevant. That's why taking care during this stage is crucial as ensuring every part is correctly fitted.

One mistake commonly made during assembly is rushing through it. Taking time to assemble each part correctly ensures that everything fits perfectly, reducing the likelihood of future defects or breakdowns.

Another mistake you want to avoid is neglecting tolerance levels. Do not assume that even if individually produced parts are within tolerance limits, they will align without some amount of adjustments for error compensation.

Finally, make sure you use proper fixing methods such as suitable adhesive or screw fasteners when assembling different parts together – using inadequate techniques may lead to loosening over time or produce structural faults on the finished component caused by incorrect tolerances accumulation due to insufficient overall stiffness increase provided by fixtures choice solutions available.

Benefits Of Proper Machining Techniques And Avoiding Mistakes

Amélioration de la qualité des produits

Improving product quality is always a top priority when machining an actuator housing. Proper machining techniques help reduce errors and defects affecting the finished product's performance.

We can ensure our final design meets all specifications by avoiding inaccurate measurements, poor material selection, or incorrect machining techniques.

Reduced Production Costs

Reducing production costs is critical to the success of any manufacturing process. Proper machining techniques can keep costs in check by minimizing waste and optimizing efficiency.

For example, accurate measurements are crucial when making a housing component. On the other hand, measurement errors mean wasted materials, scrapped parts, and lost time - all factors that increase production costs.

Another critical factor is proper material selection. High-quality materials ensure that parts last longer and require fewer repairs or replacements.

Increased Customer Satisfaction

I know that customer satisfaction is paramount in any industry. Proper machining techniques can improve the quality of an actuator housing and ultimately result in increased customer satisfaction.

We produce actuator housings that meet or exceed our customers' expectations when we avoid common mistakes such as inaccurate measurements, poor material selection, incorrect machining techniques, lack of lubrication, and improper assembly.

Amélioration de l'efficacité

Improved efficiency means the production process will become much faster, smoother, and more streamlined.

In addition, by ensuring that measurements are accurate, materials are carefully selected, lubrication is appropriately applied, and assembly is done correctly, there will be fewer manufacturing defects to correct or components to replace.

Improved Safety

Safety should always be at the forefront of your mind when machining an actuator housing, especially if you're working with heavy machinery or high-powered tools. Failure to follow proper procedures could lead to severe injuries or even fatalities.

By taking extra care and following machining procedures carefully, you can ensure that your product is not only top-quality but also safe for use by customers and end-users alike.

Proper lubrication is also critical for safety in machining an actuator housing. Without enough lubrication, friction can build up rapidly between two moving parts, causing them to break down or even lead to unexpected malfunctions during operation.

Conclusion

In conclusion, machining an actuator housing can be a daunting task. It requires precision, attention to detail, and careful planning.

However, you can ensure your product is top-notch quality with minimal production costs by avoiding common mistakes such as inaccurate measurements, poor material selection, incorrect machining techniques, lack of lubrication, and improper assembly.

To avoid these mistakes, always double-check your measurements before cutting the material. Use high-quality materials suitable for the job and follow machining procedures carefully while ensuring proper lubrication during operations.

Taking care during assembly will also go a long way in reducing errors. Asking for expert help will also lead to a successful project, so contact us now!