- Accueil

- Ressources

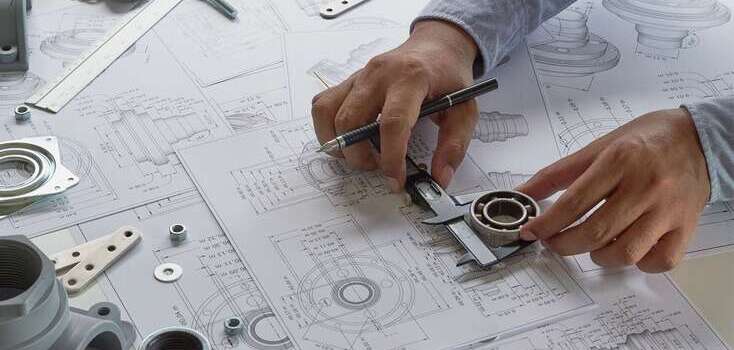

- What is Engineering Tolerance: A Detailed Guide

What is Engineering Tolerance: Un guide détaillé

Tolerance creates an allowable deviation from the given measurement of deviation when manufacturing parts in mechanical engineering.

The subject of engineering tolerance is very crucial, and for the high performance of the part it is significant too. If you want to learn what is engineering tolerance and what its types are, the guide below can help you. So, let's read.

What is Engineering Tolerance?

Engineering tolerance is the measurement deviation that is allowed from the base or the designed dimensions. This can be differentiated into temperature, weight, current, and voltage.

The tolerances in engineering can apply to linear, angular, and various other physical dimensions. The process of manufacturing has many flaws, and none of the parts can be manufactured within the given dimensions.

Hence, engineering tolerance is very crucial. It provides a permissible deviation from the geometry, but it has to be very carefully stated.

Types of Tolerances in Engineering

In engineering, there are different types of tolerances, and this section below provides details on each type.

1. Dimension Tolerances

Dimension tolerance is the allowed deviation in the component size. It refers to the maximum allowable size and the minimum allowable size for deviation.

The absolute value of the engineering tolerance is the difference between the upper limit of the minimum and the maximum.

The value of engineering tolerance cannot be zero; it is a numerical value. The smallest tolerance determines the accuracy in dimension and also refers to the difficulty in machining.

1.1 Nominal Value

The nominal value represents the fundamental dimension that is presented in the engineering sketch. The manufacturers need to keep their tolerances within the nominal value in case there are no given tolerances.

However, some deviations may take place due to the process of machining, like setup and the machinist's skills.

1.2 Upper Deviation

The upper deviation represents the lower deviation’s opposite. When you add them, it will represent how large the measurement for the components is compared to the nominal value.

1.3 Lower Deviation

The lower deviation is the tolerance allowed below the nominal value. It is an asymmetric range that has an allowance above the nominal dimension.

1.4 Bilateral Deviation

The bilateral deviation is the tolerance allowed below and above the nominal value, and the tolerance range is symmetric.

2. General Tolerances

General tolerance is a part of the components in the drawing in the form of a note or table. These tolerances are considerable in varied situations like linear dimensions, angular dimensions, and chamfer heights.

3. GD&T

GD&T is a symbol in the engineering drawing that represents the allowable deviation from the geometry of components.

It has a precise way of representing the size, orientation, form, and location of features. It also ensures that the components are meeting their functional requirements.

3.1 Form Tolerance

Form tolerance controls the features of the shape without causing any interference in the location compared to the other features. Some of the types of form tolerances are as follows:

Planéité : It ensures that the surface is within the parallel planes and a flat profile is maintained.

Rectitude : It controls the deviation of the line to stay within the given limits in a straight form.

Cylindricité : This tolerance ensures that the cylindrical surface is completely within a certain tolerance zone, ensuring consistency.

Circularité : Ensures that the circular feature’s cross-section stays round and within the given zone of tolerance.

3.2 Position Tolerance

Position tolerance provides for a given variation that is present within the location of the feature compared to the ideal location. It also ensures that the functionality and assembly are improved by controlling the exact location of slots and holes.

Some of the aspects of position tolerance are as follows:

True Position: It specifies the exact feature location.

Tolerance Zone: It defines a rectangular or cyclical zone in which the feature is located.

Datum Reference: It needs a datum system with reference so that it can be related to the position of the features with accuracy.

Fit

Engineering fits refer to the parts that mate together and their relationship. These fits are very important as they will determine the way the components will be assembled and performed.

Ajustement de l'encombrement

Clearance fit is a fit in which there is a space between the mating components left intentionally when assembling them. It is used in applications where the freedom of flexibility assembling is needed, for instance, in the parts that slide with one another.

Interférence Fit

Interference is a fit in which the dimensions of the parts are larger than the hole in which they are meant to fit. Such a fit is required to cater to components that need press fit.

In this type of fit, the parts are forced with one another to create a tough connection. It helps to offer excellent alignment, load transmission, and resistance to movement.

Transition Fit

A transition fit is a type of fit in which the mating part's dimension has interference and clearance. This means that, based on the application requirement, there will either be a minimal overlap or a minimal gap upon assembly.

Why Tolerance Matters & Where to Use It?

Tolerances are important as they ensure that the parts meet the design requirements. Manufacturers use their standard tolerance if no tolerances are specified.

Hence, when you define the tolerance, you can ensure that there won't be any dimensions in components that have deviated from the application requirements.

However, when you opt for very tight tolerance, the cost of production increases because the precision needs to align with the manufacturing methods.

Hence, only critical tolerances must be considered to ensure manufacturability, functionality, and affordability.

What Does High Tolerance Mean in Engineering?

In engineering, high tolerance means small variations in the component’s dimensions that are allowed. It requires precise and strict quality control. Parts of high tolerance are mostly opted for in industries like médical, automobile, and aerospace.

How to Choose the Right Tolerance for Your Project

The right tolerances and fits play a vital role in the project and its components. Hence, when choosing the tolerance, you need to assess some factors. Some of these are discussed below:

- You need to understand the functional requirements of the project followed by the expectations from performance and operating conditions. It helps you determine the critical dimensions that need tight tolerance.

- Make an assessment of the tolerancing process, such as casting, machining, forging, etc., to identify the achievable tolerance parameters.

- Consider the standards of the industry and the best precision so that you can opt for relevant tolerances for different projects.

- The required precision should match the time and cost constraints because tighter tolerances require more time and incur more costs.

- Always discuss tolerances with machinists, engineers, and professionals so that they can make recommendations based on their experience.

Conclusion

The significance of tolerance cannot be disregarded when manufacturing components. Hence, the guide above features detailed information that may help you with your projects.

Nous, à DEK have a team of experienced professionals to help you provide components manufactured with a tight tolerance in your budget.