Stellite Casting Service

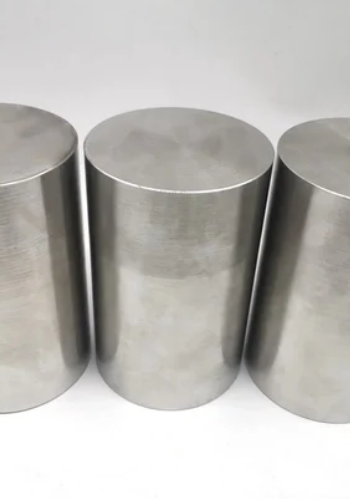

DEK offers Stellite casting to create parts that hold up in heat, friction, and tough conditions. It is ideal for valves, tools, and engine parts.

At DEK, we approach Stellite casting with precision and practicality. We build parts to last and get every detail right. Our team supports you from prototype to production with strong materials, tight tolerances, and clear communication. We work quickly and carefully to keep your project moving and on track without stress.

introduction

Stellite Casting: Heat-Proof, Hard-Wearing, Built to Last

DEK provides efficient Stellite casting for detailed, complex parts. We ensure consistent quality, dimensional accuracy, and dependable strength in parts used for critical, high-stress operations.

At DEK, you get access to advanced casting equipment and high-heat furnaces built for making strong, reliable Stellite parts. We offer gravity casting, investment casting, and precision mold options, giving you flexibility for both simple and complex shapes. You can choose from a range of Stellite alloys, and we make sure every part has a good surface finish, solid strength, and accurate dimensions. Whether you need a single prototype or a full production run, we are ready to meet your exact needs with speed and care.

You can also count on us for related services such as design support, post-casting machining, heat treatment, grinding, and full inspection. We work closely with you to match your specs, budget, and deadline. When you choose DEK, you get a hands-on team that is focused on quality and long-term performance. We help you build parts that fit right, work hard, and hold up under pressure.

- Gravity and investment casting

- Consistent quality

- High-dimensional accuracy

- Optional machining

- Minimal post-processing

- Full inspection with quality reports

Matériaux for Stellite Casting

Cobalt-Based Stellite Alloys

Stellite 1

Stellite 1 is a cobalt-chromium alloy with excellent hardness and superior wear resistance, making it ideal for abrasive and high-impact tasks. It performs well under intense heat and friction, holding its shape and edge when other materials degrade.

Through Stellite casting, you can create durable parts like extrusion dies, mining drill bits, and industrial cutting knives. Though difficult to machine, this alloy is perfect when you need long-lasting components for extreme environments. Its consistent strength at high temperatures helps reduce part failures in critical operations.

Other Designation

UNS R30001

Stellite 3

Stellite 3 is one of the hardest alloys in the Stellite family, designed to withstand severe abrasion and high-speed friction. This grade is excellent in situations where surface loss must be minimized, even under heavy wear.

It is commonly used for erosion-resistant nozzles, pump sleeves, and grinding tips. While its corrosion resistance is limited compared to other grades, its wear resistance is unmatched. You should choose this alloy when performance under mechanical and abrasive stress is the priority.

Other Designation

UNS R30003

Stellite 4

Stellite 4 balances hardness, corrosion resistance, and impact strength. It is a smart choice for parts that experience both chemical exposure and surface wear. You will often find it in compressor seals, valve seats, and sliding bushings.

Its strength at high temperatures and reliability under stress make it ideal for oil and gas, marine, and chemical industries. It also offers better machinability than harder Stellite grades. When you need dependable performance and a longer service life in corrosive environments, this alloy is a solid option.

Other Designation

UNS R30004

Stellite 6

Stellite 6 is the most widely used and versatile cobalt alloy. It offers outstanding resistance to wear, corrosion, and galling. It is ideal for parts like control valve components, rotary shear blades, and seal rings.

This alloy works well in metal-to-metal contact environments and holds its properties at high temperatures. Its impact strength and wear resistance ensure fewer breakdowns and longer part life. Stellite 6 also delivers excellent thermal stability, reducing the chance of failure during fluctuating heat cycles.

Other Designation

UNS R30006

Stellite 6B

Stellite 6B is a toughened, machinable version of Stellite 6, engineered for applications requiring impact resistance and smoother surfaces. It’s especially useful for bearing sleeves, diesel engine valve guides, and cam followers. Produced through Stellite casting, this alloy resists seizing, galling, and surface damage under extreme stress.

Its toughness means less downtime and fewer part replacements. Unlike cast-only grades, 6B allows you to finish parts with more flexibility. If you're working with components that take repeated loads or impacts, this material keeps your equipment running smoothly and reliably.

Other Designation

UNS R30016

Stellite 12

Stellite 12 provides high hardness with moderate impact resistance, making it ideal for sliding and cutting parts exposed to pressure and edge wear. You will want it for extrusion rollers, gate valve seats, and cutting blades. It holds its sharpness and shape under repetitive stress, making your equipment more durable.

Stellite 12 is an excellent choice when parts need to resist chipping, deformation, or heat damage over time. It is also weldable and maintains strong metallurgical properties in high-friction or thermally stressed applications.

Other Designation

UNS R30012

Stellite 20

Stellite 20 is a corrosion-resistant alloy developed for use in chemically aggressive environments. It is ideal for pump impellers, agitator shafts, and reactor valve internals. This grade stands up to solvents, acids, and chlorides, where other materials would weaken or corrode. It also offers good strength retention at elevated temperatures.

You should consider it for chemical plants, marine systems, or pharmaceutical facilities that require stable and long-lasting parts. Stellite 20 helps reduce equipment failures and keeps operations clean and uninterrupted.

Other Designation

UNS R30605

Stellite 21

Stellite 21 offers exceptional toughness, corrosion resistance, and thermal fatigue strength, making it suitable for critical aerospace, nuclear, and medical applications. It performs reliably in turbine vanes, orthopedic implants, and high-temperature valves. Stellite casting allows you to create complex, high-performance parts that maintain integrity under extreme thermal cycling.

The alloy resists cracking and distortion, and its biocompatibility makes it ideal for medical systems. You will appreciate its easy weldability, strong surface integrity, and stability in both oxidizing and reducing environments, making it perfect for long-term use where precision and safety are essential.

Other Designation

UNS R30021

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Nos avantages

2300+ ingénieurs Aimer travailler avec nous

Fast Lead Times

We deliver your Stellite cast parts quickly, with prototypes ready in just a few days, usually 4 to 7 days. Our streamlined process and expert team help reduce downtime and speed up development. You can count on fast responses, clear timelines, and efficient service.

Flexible Quantities

At DEK, we support any order size, with no minimums required. You can request a single prototype, a small batch for testing, or a large production run without worrying about volume restrictions. This flexibility makes it easier to manage costs and try new designs.

Alloy Options

We offer a wide range of Stellite alloy grades to meet your specific application needs. Whether you need wear resistance, heat stability, or corrosion protection, we’ll help you choose the right alloy. Our team ensures your part has the proper strength, toughness, and performance.

Full Quality Checks

We carry out thorough inspections on every Stellite cast part using advanced tools like CMMs, micrometers, hardness testers, and more. We track every detail to ensure consistent results. Our team follows strict quality control protocols to catch defects early.

Finitions sur mesure

We provide several surface finishing options to improve function or appearance, including polishing, grinding, and protective coatings. Whether you need reduced friction, better wear resistance, or a cleaner look, we’ll recommend the right treatment.

Safe Global Shipping

Your parts are packed securely using anti-rust paper, foam, and durable boxes or crates. We ship worldwide through trusted couriers like DHL, FedEx, or UPS, or arrange sea or air freight as needed. Each shipment includes clear packing lists and labels to ensure safe arrival.

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.

Envoyer l'appel d'offres 222

Revue et citation

Confirmer la commande

Production

QC

Livraison

FAQ

Stellite Casting FAQ sur l'achat

Obtenir un devis précis Pour vos prochains projets

Que votre projet soit simple ou compliqué, qu'il s'agisse de métal ou de plastique, vous obtiendrez un devis précis dans les 6 heures.

Obtenir un devis aujourd'huiSavoir Stellite Casting

What is Stellite Casting?

Stellite casting is a method used to produce high-performance parts for harsh working environments. Made from cobalt-chromium alloys, Stellite offers exceptional resistance to wear, heat, and corrosion. The molten alloy is cast into molds, allowing for detailed, custom shapes that would be difficult or costly to machine. This process is ideal for producing precision parts that require long-term reliability and minimal maintenance.

Industries such as aerospace, oil and gas, power generation, and medical rely on Stellite casting for critical components. It’s commonly used for cutting tools, valve seats, engine parts, and turbine blades, applications where strength, accuracy, and durability are essential under constant stress and extreme temperatures.

What are the Advantages of Stellite Casting?

Stellite casting offers unique benefits that make it a smart choice for high-performance parts. It not only handles tough conditions but also gives you design flexibility, material consistency, and reliable results even in small or complex orders. The process supports a wide range of applications across different industries.

Key Advantages of Stellite Casting:

- No Need for Heat Treatment

- Une qualité constante

- Flexibilité de la conception

- Good Surface Finish

- Small to Large Batch Capability

When Do You Need Stellite Casting?

You need Stellite casting when your parts must stay reliable in extreme or unpredictable environments. If you're dealing with frequent part failure, rapid wear, or constant exposure to chemicals, heat, or abrasion, Stellite casting offers a dependable solution. It is especially useful when traditional materials like steel or aluminium can not hold up over time.

Stellite casting is also the right choice when you need custom-shaped parts that are hard to machine or too costly to produce by other methods. It’s ideal for limited production runs, urgent replacements, or when you need tight tolerances without extra processing. Whether you're designing something new or upgrading an old part, Stellite casting helps you get performance that lasts.