- Accueil

- Ressources

- What is Ultra Precision Machining: Techniques, Materials, Applications

What is Ultra Precision Machining: Techniques, Materials, Applications

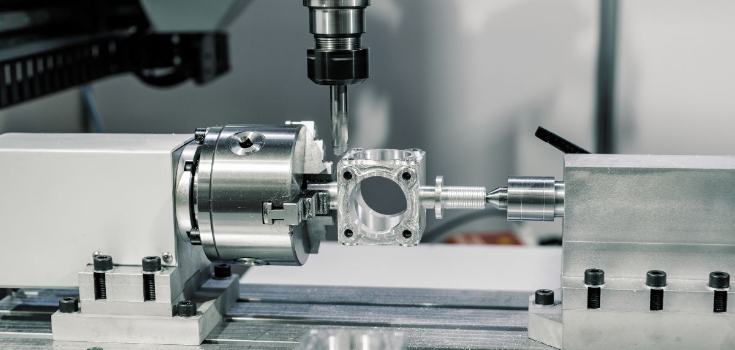

Ultra Precision Machining is the latest form of precision manufacturing that demands exceptional surface finish quality and dimensional accuracy. To produce items with a limit in the submicron range, specific CNC milling and turning equipment is needed.

It works well for machine parts that need to be extremely accurate. For instance, the optical, medical, and aerospace sectors. This article will cover what is ultra precision machining, its methods, the materials used, and its many industrial uses.

What is Ultra Precision Machining?

Ultra Precision Machining means the creation of the components with precision accuracy in the submicron or nanometer domain. The process depends on CNC milling and turning equipment with high control, environmental stability, and advanced cutting tools.

It takes out the smallest evidence of surface irregularities. It produces parts of a very smooth and consistent nature. It is generally applied in cases where performance depends on microscopic precision, optical lenses, micro-molds, and sensor components.

Ultra-Precision Machining vs Conventional Machining

| Fonctionnalité | Ultra Precision Machining | Conventional Machining |

| Précision | Submicron or at a nanometer level | Micrometer level |

| Finition de la surface | Mirror-like finish (Ra < 0.01 μm) | Standard finish (Ra > 0.2 μm) |

| Equipment Used | CNC ultra-precision lathes and micro mills | Standard CNC machines |

| Outils de coupe | Diamond-tipped tools, micro cutters | Carbide or HSS tools |

| Application | Optics, semiconductors, aerospace | General metalworking, industrial parts |

| Coût | Higher initial cost | Lower initial cost |

| Volume de production | Ideal for prototypes and small batches | Suitable for mass production |

Key Techniques in Ultra Precision Machining

Ultra Precision Machining has various advanced techniques to maintain the accuracy of the order of sub-micron and surface finishes that do not show flaws. Each technique is optimized for various materials and end-use requirements.

Micro Turning and Micro Milling

These two methods are really important for CNC machining processes. Small complex parts could be formed with very fine dimensional standards. An ultra-sharp diamond tool and the precise use of spindle controls are important features of both processes.

Micro milling removes nearly no material per single pass and thus maintains narrow tolerances. On the other hand, Micro turning is most suitable for production of rotating or reversible components. These are minute shafts and optical housings.

Ultra Precision Polishing and Grinding

Ultra precision polishing and grinding are finishing operations that take away all kinds of surface defects. They give a mirror-like smoothness. These methods are conducted under controlled conditions to minimize vibration and heat generation.

Polishing tools made from soft abrasives ensure accurate surface correction without introducing dimensional inaccuracies. In comparison, consistent surface texture and geometry is achieved by the use of grinding for hard materials.

Micro-Precision Laser Machining

Micro-precision laser machining makes use of focused laser beams to vaporize material on a microscopic scale. This is non-contact so that tool wear and mechanical distortion would be absent.

It is used in the micro-holes, fine slots, and delicate contours in (ceramic and polymer). Laser path can be programmed for precise repeatability using CNC integration.

Electrochemical Machining (ECM)

Electrochemical Machining is an alternative procedure. In this process, material is removed by using highly controlled electrical energy and chemical interactions. Acts as an effect free surface and does not cause thermal damage.

The ECM is very much suitable for hard and electrically conductive materials which physically very complex to use. However, it guarantees constant accuracy, even in complex geometries, of thin-walled parts.

Micro-Electroplating

Micro-electroplating improves part productivity by applying thin layers of metal on a base material. It improves corrosion resistance, hardness, and electrical conductivity.

This technique is majorly used in semiconductor and micro-electromechanical systems (MEMS) manufacturing. During this, surface quality and dimensional integrity are important.

Materials Used in Ultra Precision Machining

Métaux

High-purity aluminum, copper, acier inoxydable and titanium are commonly used since they have excellent machinability and strength. In micro-cutting and polishing operations, these metals perform excellently well.

Céramique

Exceptional hardness, heat resistivity and stability enable ceramics respond excellently in optical and semiconductor parts. Also advanced diamond grinding precision leaving no cracking or distortion.

Polymères

High-performance polymers such as PEEK and PTFE are applied in demanding applications where lightweight and chemical resistance stand important advantages. Their inert properties during machining are maintained during CNC milling and turning processes.

Semiconductor Materials

![]()

Silicon and gallium arsenide are one of the most important materials in the semiconductor industry. Ultra Precision Machining achieves smooth surfaces and dimensions highly essential in production of wafers and microelectronics.

Composites

Composite Materials are one of the important aspects of construction concerning strength and lightweight structure. Custom Precision Machining makes them perfect and homogenous. They can be used in aerospace and defense components.

Factors Impacting Ultra-Precision Machining Performance

Machine Stability: Any vibration can modify surface finish and structural accuracy.

Tool Quality: Diamond or ultra-hard tools boost accuracy and surface smoothness.

Environmental Control: Regulating temperature and humidity is vital for maintaining sub-micron measurements.

Material Properties: Hardness, thermal conductivity, and brittleness in a material inform its machining capability.

Cutting Parameters: Feed rate, spindle speed, and depth of cut influence accuracy and tool life.

Challenges in Ultra Precision Machining

Ultra Precision Machining faces difficulties. High operational costs, limited materials available for processing, and cutting tool wear during extended operations. On top of these two, consistent environmental stability and the handling of most of the processes and measurements at micro-scales require special capabilities and equipment.

On the other hand, CNC technology and automation, have improved the efficiency and repeatability in spite of this limitation.

Applications of Ultra Precision Machining

Aérospatiale : Manufacturing components of turbines, sensors, and micro-valves.

Optics: Manufacturing of lenses, mirrors, and surfaces reflective to light.

Dispositifs médicaux : Making of instrumentation and components to be implanted.

Semiconductor Industry: Wafer, mold, and micro-electronic component manufacturing.

Automobile : Precision components for fuel systems and control units.

Défense : Components of high accuracy for targeting and navigation systems.

High-Quality CNC Machining HDPE at DEK

Au DEK, world-leading CNC machining services provide advanced milling, turning, and precision processes combined. The skill of the team gives expert DFM feedback for efficient manufacturing with superior quality. Each project will be executed with precision and repetition. DEK ensuring reliable and top-performing results for your most important needs.

Conclusion

Manufacturing is redefined by ultra precision machining, which achieves consistency, accuracy, and surface quality that are not achievable with historically techniques. It is necessary for the production of valuable parts for a variety of industries.

With ongoing advancements in CNC technology, this machining keeps pushing the boundaries of accuracy and performance into the next generation.