SLS 3D Printing Service

SLS 3D printing uses modern technology to produce high-quality and durable components. If you require accurate prototypes, this manufacturing technique is suitable.

At DEK, we provide highly functional, complex geometry components that meet every client's requirements. Our SLS 3D printing service isn't only cost-effective and of high quality, but we also ensure you get your prototypes and production components as fast as possible.

introduction

SLS 3D Printing Service: High Quality, Efficient, and Fast

DEK offers you printing services with great accuracy, mechanical properties, and exact precision. We offer our services following strict industry standards, even while charging you less.

Through our sophisticated modern technological facilities and our team of experts, we handle every client's order based on their requirements. We are widely recognised for our quality production parts and fast manufacturing procedure. Contact us today.

Whether you need a low, mid, or high volume production, we have the manufacturing materials, machines, tools, and the team of experts to care for your next SLS 3D printing project.

- Géométries complexes

- High-quality material

- Reliable production

- Délai d'exécution rapide

- Des prix compétitifs

Impression 3D SLS Matériaux

Plastiques

Nylon

PA, or Nylon, is a strong, wear-resistant plastic offering excellent toughness, thermal resistance, and mechanical strength. It is a versatile and cost-effective material, making it suitable for precise SLS 3D printing service.

DEK relies on PA for high-performance SLS parts with fine detail and consistent quality. Whether you're in aerospace, robotics, or manufacturing, we ensure you receive high-precision, production-ready components that perform under pressure. Nylon is also widely used in industrial applications for functional prototyping and end-use parts.

Notes

Nylon 6, Nylon 6 (30% glass filled), Nylon 6/6 (30% glass filled), Nylon 6 flame retardant.

PEI

PEI is an amorphous thermoplastic offering excellent heat and chemical resistance, flame retardancy, and dimensional stability. Its unique properties make it ideal for applications involving high temperatures and electricity.

You can count on DEK to deliver high-strength PEI components with high precision and smooth finishes. We manufacture parts that retain dimensional accuracy in critical sectors like electronics and aerospace, ensuring long-term reliability. Perfect for aerospace brackets, automotive lighting, electrical connectors, Medical devices, etc.

Notes

PEI Ultem 2300, PEI Ultem 1000

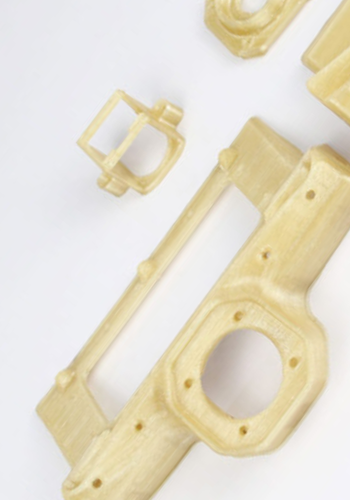

PEEK

PEEK is a high-performance plastic known for its exceptional mechanical strength, heat resistance, low moisture absorption, and chemical stability. They can be easily machined, and they maintain their physical properties even at high temperatures.

At DEK, we print complex PEEK parts for highly demanding fields. With our top-tier precision and attention to finishing, you can trust us to deliver components that meet strict industry standards every time. We machine PEEK for applications in industries like aerospace, medical, electrical, and automotive.

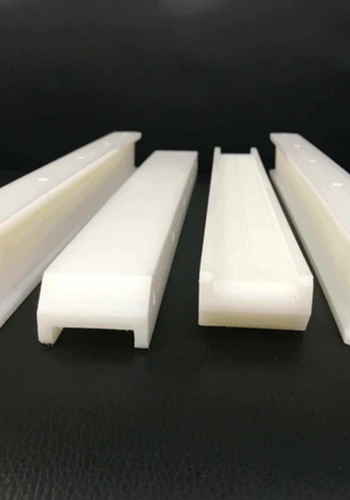

PE

Polyethylene is a tough, cost-effective, impact-resistant plastic with excellent chemical resistance and low moisture absorption. It's ideal for lightweight parts that require durability in harsh environments.

We at DEK use PE to create flexible, wear-resistant parts with high accuracy and clean finishing. From packaging tools, medical equipment, to industrial fittings, you get reliable performance and precision in every part we print for your business.

Suitable for producing water pipes, containers for food storage, trash bags, medical implants, agricultural mulch, etc.

PPSU

PPSU is a high-performance thermoplastic with excellent hydrolysis resistance, toughness, transparency, impact strength, and ability to withstand repeated sterilisation, making it suitable for application in highly demanding industries.

At DEK, we print PPSU parts that meet demanding cleanliness and durability standards. With excellent accuracy and finishing, you get components that perform reliably even in high-temperature or chemical-exposed environments. Our PPSU printed components are valuable in industries like automotive, aerospace, electrical, in creating connectors, plumbing fittings, laboratory equipment, and so on.

PP

Polypropylene is a lightweight, semi-crystalline thermoplastic known for its excellent chemical resistance, flexibility, and fatigue endurance. It offers good impact strength and low moisture absorption, making it versatile for use.

At DEK, we use PP in SLS 3D printing services to produce durable, lightweight parts with high accuracy and excellent surface finish. Whether you need automotive or medical components or consumer goods, we ensure each part meets your exact requirements with outstanding strength and clean detail. Perfect for construction materials, stationery items, medical devices, etc.

Notes

Homopolymère de PP, PP+GF(30%)

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Nos avantages

2300+ ingénieurs Aimer travailler avec nous

Tight Precision

You can rely on DEK for high-precision parts. Our SLS machines consistently deliver parts with high precision, ensuring every detail of your design is preserved. Whether it’s for mechanical fit, functional testing, or end use, we give you the accuracy your application demands.

Délai d'exécution rapide

Time is valuable, and we don’t waste it. We deliver rapid production within short lead times, thereby allowing you to move quickly from concept to completion. Whether you need prototypes or production parts, we make sure they arrive on time.

Industrial Grade Quality

When you work with DEK, you get durable, functional parts built for real-world use. Our SLS printing process produces high-strength components that can withstand heat, wear, and stress. We ensure every part is production-ready and built to last.

Rapport coût-efficacité

With DEK, you save on tooling and setup costs. SLS is ideal for low to medium-volume production, making it far more economical than injection molding for custom or short-run parts. We help you cut costs without compromising on quality or durability.

Emballage professionnel

Every part we produce is carefully cleaned, inspected, and professionally packaged before shipping. DEK takes pride in presentation and protection, ensuring your components arrive in perfect condition, ready to use, test, or deliver to your customers.

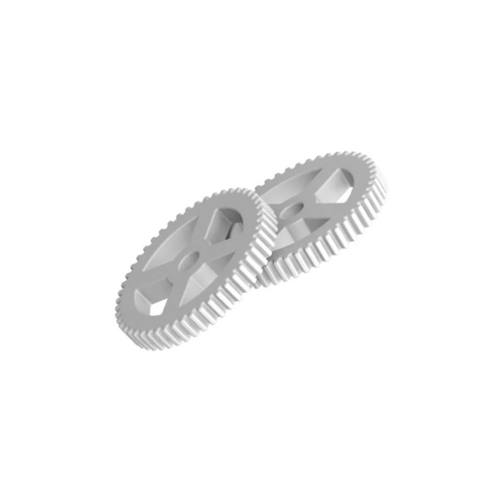

Design Freedom

With DEK’s SLS 3D printing service, you can create complex, interlocking, or hollow designs that would be impossible with traditional methods. Since no support structures are needed, you have complete freedom to innovate. We help you turn bold, functional ideas into high-performance parts with confidence.

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.

Envoyer l'appel d'offres 222

Revue et citation

Confirmer la commande

Production

QC

Livraison

FAQ

Impression 3D SLS FAQ sur l'achat

Obtenir un devis précis Pour vos prochains projets

Que votre projet soit simple ou compliqué, qu'il s'agisse de métal ou de plastique, vous obtiendrez un devis précis dans les 6 heures.

Obtenir un devis aujourd'huiImpression 3D SLS Overview

Qu'est-ce que l'impression 3D SLS ?

SLS (Selective Laser Sintering) is an advanced 3D printing technology that uses a high-powered laser to fuse powdered thermoplastic material layer by layer into solid objects. Unlike other printing methods, SLS doesn’t require support structures, allowing you to create complex geometries, enclosed features, and interlocking parts with ease.

You can produce functional prototypes and end-use parts directly from your digital design. At DEK, we use industrial-grade SLS machines to deliver strong, accurate, and reliable parts for a wide range of applications, from aerospace and medical components to wearable consumer products.

What are the Advantages of SLS 3D Printing?

SLS 3D printing services offer you a wide range of benefits. You can create parts with excellent mechanical strength and high detail resolution. At DEK, we help you take full advantage of these benefits with expert support and precision manufacturing.

- Production of tough and durable components

- High dimensional accuracy and precision

- Wide range of material to choose from

- Délai d'exécution rapide

- Ideal for complex geometries

- Cost-effective for small and large production

- Ideal for functional prototypes

When Do You Need SLS 3D Printing?

You need SLS 3D printing service when your project requires durable, accurate, and functional parts, especially if the geometry is too complex for traditional manufacturing. It’s ideal when you’re creating functional prototypes, testing mechanical assemblies, or producing low-volume end-use parts.

You can also use SLS when speed matters and tooling costs are a concern. If your part needs to be strong, heat-resistant, or flexible, SLS gives you the right material options. At DEK, we recommend SLS when you want rapid, cost-effective manufacturing without sacrificing performance or design freedom.