- Accueil

- Ressources

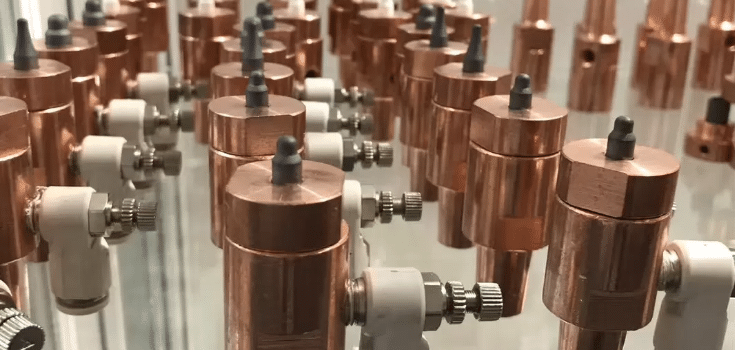

- KCF Guide Pin: Everything You Should Know

KCF Guide Pin: Tout ce qu'il faut savoir

Precision manufacturing requires some considerations to be in place so that optimal results are achieved, and among that, positioning is also important.

In order to achieve the precise position, the KCF guide pin plays a vital role. Now, what is a KCF guide pin, what are its pros and cons, and what are its applications, are all discussed in the guide below. So, let's read.

What is a KCF Guide Pin?

A KCF guide pin is a tool that helps to align components during the machining process. KCF stands for Key Control Function, and these pins are used in processes like stamping, assembly, and welding.

They are made using a KCF alloy, which offers high wear resistance and durability. Moreover, these guide pins are also suitable for environments subjected to high temperatures.

The main significance of KCF guide pins is their ability to ensure precision during manufacturing processes. The alignment of the components using KCF guide pins helps in reducing errors and production downtime. It even leads to improving the quality of the part.

Overview of KCF Technology

KCF technology is associated with the process of manufacturing guide pins, which are made from the unique composition of the KCF alloy.

These pins are manufactured to be used in environments where they are subjected to extreme temperatures and wear and tear. The KCF alloy is capable of handling such situations while maintaining strength and accuracy.

KCF technology helps prevent weld spatter adhesion, which enhances the performance of the guide pins during welding processes.

The nonstick property of these pins ensures wear resistance, consistency in alignment, and durability. Hence, it is used in many industries where production efficiency is essential.

Pros of KCF Guide Pins

The KCF guide pins offer various advantages, some of which are as follows:

- These pins are made using a special alloy, which is durable and offers high resistance against wear, which makes them suitable for high-stress applications.

- KCF guide pins are also capable of withstanding extreme temperatures and maintaining their structural integrity.

- KCF guide pins can resist weld spatter adhesion which reduces the maintenance requirements and downtime. The adhesion is the result of the spatter that is created during the welding process.

- These KCF guide pins ensure the accurate alignment of components, which helps enhance the efficiency of the production processes.

Cons of KCF Guide Pins

The KCF guide pins also have some downsides, which are as follows:

- KCF pins are manufactured using specialized KCF alloy due to their properties, and hence, these pins are expensive.

- KCF guide pins are opted in welding applications where high heat is prevalent and hence cannot be suitable for the simple processes of manufacturing.

- KCF guide pins may not be available everywhere and may need time for arrangement.

Types of KCF Guide Pins

The different types of KCF guide pins used for precision manufacturing processes sont les suivants :

Tapered KCF Guide Pins

Tapered KCF guide pins have a tapered design that is used in applications where positioning and alignment of the components are crucial so that assembly errors are present. These pins are smoothly inserted into the components.

Threaded KCF Guide Pins

Threaded KCF guide pins have threads to help secure the pins in the components easily. These are suitable for such applications where the guide pins need a firm fixation, like tooling systems.

Shoulder KCF Guide Pins

Shoulder KCF guide pins have a collar that offers additional support and protects the pin from being pushed away during the assembly process. It is used in applications that need a control on the depth.

Design Considerations for KCF Guide Pins

The KCF guide pins do have some design considerations so that they can function appropriately, and some of these are as follows:

- The materials used in the KCF guide pins should be the KCF alloy because the application of these guide pins requires the properties possessed by the KCF alloy.

- The KCF guide pins must be manufactured with precise dimensions so that they can help with perfect assembly. In this case, considerations like length, tolerance, and diameter of the guide pin should be based on the application requirement.

- There are different shapes that can be chosen for the pin, like tapered, threaded, or straight. Similarly, the design of the tip can be rounded or flat-based application.

- KCF guide pins are meant for high-temperature environments, and when designing them, the type of environment they will be used in should be assessed to ensure their durability and performance.

Applications of KCF Guide Pins

The KCF guide pin is used in many applications, such as welding and assembly. Some of these applications are as follows:

Secteur automobile

In the automobile industry, KCF guide pins help with welding components. These components consist of body panels mostly as these pins offer resistance against heat and weld spatter, and the position of the components can be well aligned.

Emboutissage de métaux

Metal stamping uses KCF guide pins so that the dies can be aligned with the materials appropriately. These pins ensure that they withstand repeatable usage during the process of metal stamping.

Secteur aérospatial

Le aérospatiale sector needs components to be assembled with high precision. The KCF pins are used in welding and assembling processes, and offer alignment of the components with accuracy. Components like fuselage panels are usually manufactured using KCF guide pins.

Industrie électronique

The electronics industry uses KCF guide pins to assemble delicate components. These pins offer electrical insulation and hence can be used in such applications without the risk of electrical interference.

Conclusion

KCF guide pins have multiple uses, but the most important thing is that they must be designed with high precision and accuracy. We at DEK manufacture the KCF guide pins using KCF alloy, which helps you with precision assembly.

So, get in touch with us today and get the KCF guide pins manufactured to meet your application requirements.