- Accueil

- Ressources

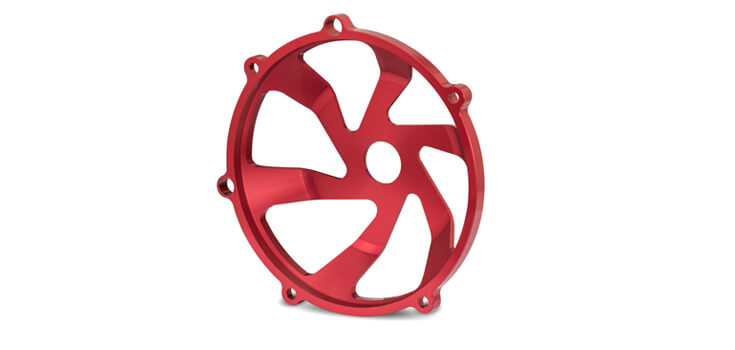

- How to CNC Machine a Clutch Cover for High Performance Vehicles

How to CNC Machine a Clutch Cover for High Performance Vehicles

Every component matters in achieving maximum efficiency and speed for high-performance vehicles. However, one essential part that often goes unnoticed is the clutch cover, which significantly influences your vehicle's performance.

With CNC machining taking center stage for precision manufacturing, customizing a clutch cover has never been easier or more accurate.

Understanding CNC Machining And Clutch Covers

Importance Of Clutch Covers In High-performance Vehicles

When it comes to high-performance rides, having a reliable and durable clutch cover becomes even more significant as they operate under extreme conditions that demand consistent engagement and disengagement without slipping or failure.

Over time, I've witnessed various instances where fellow enthusiasts invest heavily into their engines for increased horsepower but neglect their clutch system components like clutch covers.

As a result, they face dire mechanical consequences that could have been easily avoided with an upgraded and sturdy cover tailored for high-stress environments.

A well-designed CNC machined clutch cover delivers enhanced grip while reducing slippage. It contributes to improved heat dissipation – an essential element when dealing with powerful engines on race tracks or during aggressive driving sessions on regular roads.

Benefits Of CNC Machining a Clutch Cover

- High Precision and Tight Tolerances

- Personnalisation

- Quality Materials

- Géométries complexes

- Consistent Results Across Multiple Production Runs

- Faster Production Cycles and Quicker Turnaround Times.

- Réduction des déchets

- High-Quality Surface Finish

- Prototyping and Small Runs

- Compatibilité

- Fewer Defects and Improved Quality

- Integration of Features

- Material Strength

- Rapport coût-efficacité

- Improved Performance

- Automated Tool Changes

Steps for CNC Machining a Clutch Cover

Designing The CAD Model For The Clutch Cover

- Use computer-aided design (CAD) software to create a detailed 3D model of the clutch cover. Include dimensions, features, and any customization.

- Ensure the design follows the functional requirements and aesthetics of the clutch cover.

Selecting High-performance Materials And Tooling

- Material selection: High-performance vehicles require clutch covers that can withstand the high stress and heat generated by the engine. Materials such as aluminum, titanium, and stainless steel are commonly used due to their strength, durability, and resistance to corrosion.

- Tooling selection: The quality of tooling used in CNC machining directly impacts the quality of the finished product. Carbide or diamond-coated tools are commonly used for their ability to withstand high speeds and temperatures while maintaining their sharpness.

- Cutting parameters: The cutting speed, feed rate, and depth of cut must be carefully selected to ensure optimal performance and precision.

- Lubrication: Proper lubrication keeps the cutting tool cool and reduces friction between the tool and the workpiece. Water-soluble coolant is commonly used in CNC machining.

Programming The CNC Machine

- Use computer-aided manufacturing (CAM) software to generate tool paths based on the CAD model. Define the cutting operations, speeds, feeds, and tool changes.

- Optimize the tool paths to ensure efficient material removal and surface finish.

Operating The CNC Machine For Clutch Cover Production

- Mount the material: Mount the material onto the machine's bed, ensuring it is securely clamped in place.

- Select the appropriate tooling: Choose the right tooling based on the type of material you're using and the design specifications for the clutch cover.

- Load the program: Load the appropriate program into the machine's computer system, allowing it to begin cutting and shaping the material according to your design.

- Run a test cut: Before you start full production, run a test cut to ensure everything works properly and your settings are correct.

- Begin production: Once you've completed your test run, you can begin full-scale production of your clutch covers.

- Monitor progress: It's important to monitor progress closely throughout the machining process to ensure everything goes smoothly and that each part meets your exact specifications.

Choosing The Right CNC Machining Service For Clutch Covers

Expérience et expertise

Look for a machining service with a proven track record of working on similar projects, especially those involving clutch covers or similar automotive components.

Check their industry experience, certifications, and references to gauge their expertise.

Expérience et expertise

Look for a machining service with a proven track record of working on similar projects, especially those involving clutch covers or similar composants automobiles.

Check their industry experience, certifications, and references to gauge their expertise.

Technology and Equipment

Ensure the machining service has modern CNC machines and technology suitable for producing clutch covers to your specifications.

Inquire about various machining capabilities, such as multi-axis machining, precision milling, and turning.

Compatibilité des matériaux

Verify that the machining service can work with the materials commonly used for clutch covers, such as aluminum, steel, or specialized alloys.

Ask about their experience with machining specific materials and how they handle material selection.

Customization and Design Support

If you require customized clutch covers, ensure the service can assist with CAD/CAM design and provide input on design optimization for manufacturability.

Quality Control and Inspection

Inquire about the quality control measures they have in place, such as inspection tools, processes, and quality assurance protocols.

Ask if they can provide documentation of quality testing and inspection results.

Tolérance et précision

Clutch covers require precise dimensions and tight tolerances. Ensure the machining service is capable of consistently meeting these requirements.

Lead Times and Capacity

Assess their production capacity and lead times. A reliable machining service should be able to meet your production deadlines without compromising quality.

Communication and Collaboration

Choose a service that values open communication and collaboration. They should respond to your inquiries, provide regular updates, and address concerns.

Value for Cost

While cost is a factor, prioritize value over the lowest price. Consider the overall quality, reliability, and expertise of the machining service.

Reviews and Reputation

Look for online reviews and testimonials from past clients to gain insights into their reputation, reliability, and the quality of their work.

Location and Shipping

Consider the location of the machining service with your facility or distribution network. This can affect shipping costs and lead times.

Sustainability and Environmental Practices

If sustainability is a concern, inquire about the machining service's environmental practices, such as waste reduction, energy efficiency, and responsible material disposal.

Conclusion

In conclusion, Usinage CNC has revolutionized the production of clutch covers for high-performance vehicles. The precision and accuracy achieved through this process far surpass traditional manufacturing methods, resulting in increased strength, durability, and customization options.

Choosing the right CNC machining service is essential for producing top-quality clutch covers that optimize vehicle performance. Look for experienced engineers with industry-leading technology and a commitment to quality assurance processes.

The future of CNC machining in the automotive industry is bright as new techniques emerge to improve efficiency and product excellence. So whether you're looking to upgrade your vehicle or build a custom engine from scratch, CNC machining provides endless possibilities for achieving optimal performance upgrades.