- Accueil

- Ressources

- How to Achieve Precision in Medical Parts: Informative Guide

How to Achieve Precision in Medical Parts: Informative Guide

When you make medical parts, you need to be very exact because a small mistake can cause serious problems. That’s why it’s important to know how to achieve precision in medical parts.

In this guide, you’ll learn what precision machining is and how you can make sure every part you make is accurate, safe, and ready to use for the medical industry.

What is Precision Machining?

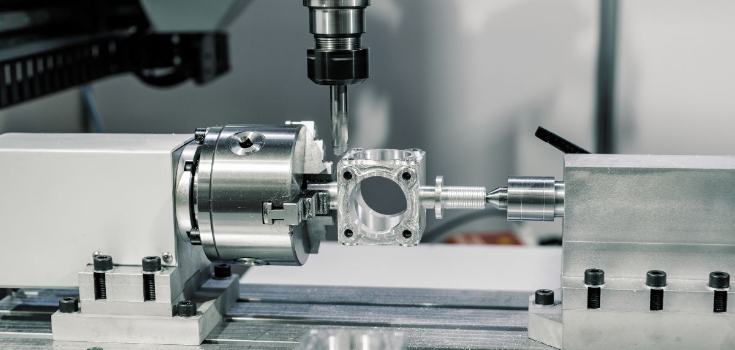

Precision machining means making parts that are almost exactly the same size with little difference. You do this by using machines controlled by computers, like CNC machines or lasers. You also want the parts to match the original design exactly.

The Role of Precision in Medical Parts Manufacturing

As medical care improves, the need for precise devices grows to help people stay healthy. Since these devices affect health, every part must be made with great care. They must work perfectly, especially inside the body, where mistakes can be serious.

To achieve this, you can use different precision machining processes that we will discuss further below.

Benefits of Precision Machining in the Medical Industry

You can get a lot of benefits when you use precision machining in the medical industry, and some are discussed below.

Make Precise Devices

With precision machining, you can create medical devices that are very accurate. Tools like 5-axis milling and EDM allow for detailed and smooth parts, even with tough materials.

Make Devices from Different Materials

Precision machining lets you use strong materials like surgical steel and titanium, which meet FDA safety standards. These materials are used in things like implants and surgical tools.

Make Smaller Devices

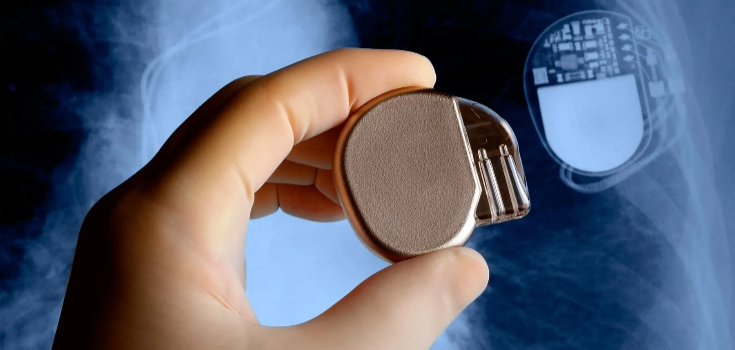

Precision machining helps create smaller devices like insulin pumps and pacemakers. These devices are comfortable and don’t get in the way, so it is easier for people to live their daily lives.

Tools and Technologies Used in Precision Machining

Precision machining in making medical components uses different tools and technologies, such as:

Machines CNC : These machines are controlled by computer programs to ensure precise and repeatable machining for you.

CAD/CAM Software: This software helps you design medical components and generate instructions for the machining process.

Advanced Cutting Tools: Tools made of carbide, ceramic, and high-speed steel are used to get the precision and quality you need for medical components.

High-Speed Machining (HSM): This technology speeds up machining. It makes the process more efficient and improves your productivity.

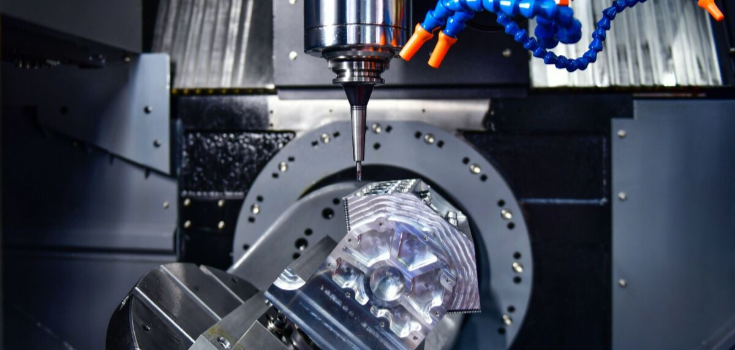

Multi-Axis Machining Centers: These machines can perform complex operations from different angles. They can help you create detailed medical parts.

Metrology Equipment: Tools like coordinate measuring machines (CMMs) and laser trackers check the accuracy and quality of the components you make.

Precision Machining Processes for Medical Component Manufacturing

Here are some of the precision machining processes that you can use:

Usinage CNC

This method uses computers to control machines. It makes parts precise and consistent every time.

5-Axis Milling

The advanced technique lets you create complex shapes in one setup, reducing mistakes and saving you time.

Usinage par décharge électrique (EDM)

This is used for hard materials like titanium and tungsten. It uses electrical discharge to shape the material. It makes highly detailed and precise parts.

Importance of Quality Control in Precision Machining for Medical Industry

Below are the main reasons why it’s so important:

- Ensure every part is made exactly right for patient and user safety.

- Regular quality control leads to parts that are less likely to fail.

- Catch problems early to avoid costly fixes and delays.

- Follow industry rules to maintain safety and quality standards.

Challenges for Precision Medical Machining

In medical machining, you need to avoid contamination, keep up with new tech, and manage high costs. Below are some of the other challenges you might encounter and how to solve them.

Working with Titanium

Titane is a hard material, so it is often used because it’s strong and lasts a long time. You might use it to make biopsy tubes or surgical scissors. These tools help doctors collect tissue samples or perform surgeries.

But titanium is hard to work with, so you must use special tools and make the machining speed slower if needed.

Making Complex Parts with CNC

The human body is complicated, and medical tools need to match that. Use 5-axis CNC machines for detailed, multi-angle cuts. Use software to simulate the process before cutting real material.

Handling Tight Tolerances

When you make medical parts with CNC machines, you often deal with very tight tolerances. Use high-precision machines and inspection tools. Run regular quality checks to catch problems early.

Small Batch Orders

A small batch order usually means fewer than ten parts. You can make these small batches with CNC machines or 3D printers.

Applications of Precision in Medical Parts

Now, here are some examples of medical parts that need precision machining:

Implantable Devices

Lorsque vous travaillez avec pacemakers, stents, or bone implants, you need tiny, precise parts made from safe materials like titanium.

Équipement de diagnostic

You use precision-machined parts in MRI machines, CT scanners, and ultrasound devices. These parts help you get clear, high-resolution images, which are important for making the right diagnosis.

Instruments chirurgicaux

You use precision machining to make sharp tools like scissors, forceps, and other surgical instruments. This process helps you get clean edges without rough spots, so your tools are safe and work well during surgery.

Endoscopic Tools

You count on flexible, detailed tools to look inside the body. Precision machining helps you build parts that move easily and work exactly as needed during challenging procedures.

Aides auditives

For hearing aids, you need tiny, detailed parts. Precision machining lets you create these small pieces and circuits with the accuracy and size needed to keep the devices light, comfortable, and effective.

Respiratory Equipment

You use precision-machined parts in ventilators and other breathing devices. These parts must work perfectly, especially in emergencies.

Precision Machining for Medical Devices From DEK

DEK offers precision machining for medical devices. We use various tools and methods, like CNC and EDM machining, laser cutting, laser welding, and additive manufacturing. We also handle sheet metal fabrication and other finishing services.

We can give you different options, so you get what works best for your needs. Contactez nous to talk about your next medical device project or get a free quote.

Conclusion

Precision machining is important for improving medical technology. It helps make tiny, accurate parts needed for advanced medical devices. This process makes sure the parts are lightweight, strong, and work well.