- Accueil

- Prototypage automobile

Prototypage automobile Services

We provide precision automotive prototyping and engineered components, enabling rigorous design validation for advanced, next-gen mobility systems.

- Tight-tolerance components via CNC and industrial 3D printing.

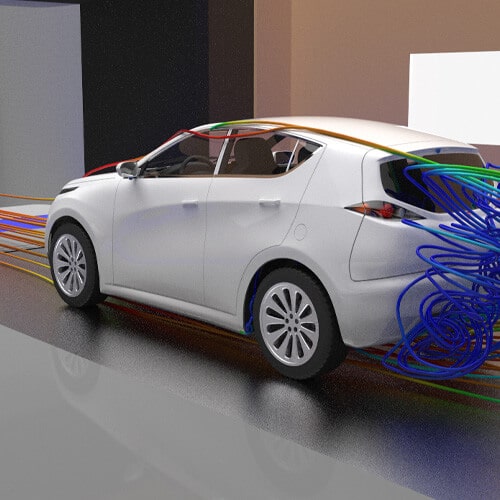

- Optimized physical models for wind tunnel and airflow testing.

- Expert assembly of intricate powertrain and electronic sub-systems.

- Specialized alloys and polymers meeting strict automotive standards.

- Stress-tested frames built for impact and fatigue analysis.

Prototype automobile Services

DEK provides world-leading automotive prototyping and custom parts, using advanced CNC machining, casting, tooling, and 3D printing to ensure cost-effective quality.

With access to over 50 certified materials and professional experienced technical support, DEK excels in automotive prototyping, while also providing haute précision (tolerances up to +/-0.005mm) customized automotive parts for your project with une qualité constante et livraison rapide.

Our goal is to exceed our customers' expectations and help you succeed in the marketplace. DEK has no minimum order quantity and can save you an average of 40% cost by recommending the right process for your project. In addition to surface finishes options, we can also provide expedited service to meet urgent customer needs. Our strict adherence to ISO 9001 standards ensures that automotive prototypes and parts meet design requirements for size, performance and durability.

Pièce de moteur automobile

Pièce de moteur automobile

Pare-chocs pour voiture

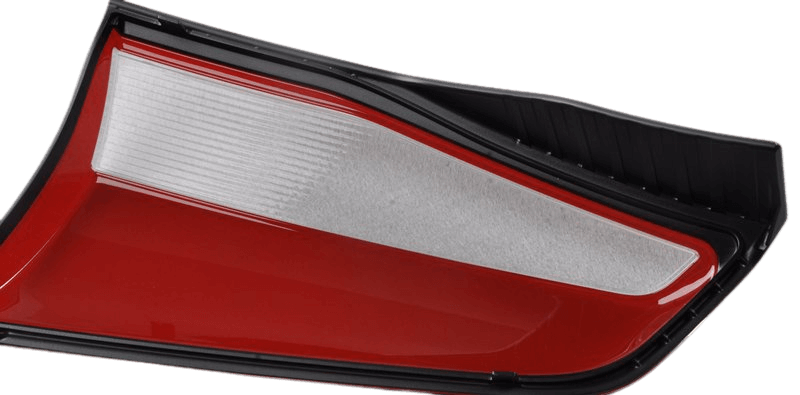

Auto Lamp Len

Réflecteur de phare de voiture

Partie structurelle

Auto Starter Part

Car Body Part

Prototypage automobile Capacités

Usinage CNC

DEK has state-of-the-art CNC machining centers with 3-axis, 4-axis, 5 axes for a wide range of metals and plastics, including aluminum, titanium, stainless steel, ABS, acrylic, nylon, and other product-grade materials.

Our engineering and production teams have the experience and design flexibility in automotive prototyping and component production to quickly produce physical prototypes of complex geometries and shorten development cycles. We can provide you with cost-effective quotes based on market prices and quickly deliver high-quality parts.

Coulée sous vide

DEK specializes in exterior prototype parts for automobiles made using vacuum casting methods, such as light housings and bumpers, as well as functional parts with complex internal structures.

We offer more than 50 types of certified materials and the flexibility to produce the automotive prototypes or parts you need to ensure that the end-use parts meet your project requirements. With our advanced equipment and proven vacuum casting technology, we can quickly manufacture complex-shaped parts.

Outillage rapide

When multiple identical plastic prototypes need to be built, our rapid tooling services are your best solution. We use aluminum molds and silicone molds for manufacturing.

Using a combination of rapid tooling and injection molding manufacturing methods, DEK is able to create hundreds of custom automotive parts, including bumpers, reflectors, light guides, bezels, exterior lenses, and other components for our customers in a much shorter period of time.

Fabrication de tôles

DEK provides high-quality, reliable sheet metal fabrication for precise dimensions. Our proven processes deliver cost-effective, durable prototypes and custom parts with superior structural stability.

We use lightweight materials like aluminum, HSS, and magnesium to enhance vehicle performance and energy efficiency. Our secondary services include painting, galvanizing, and polishing to improve component durability and aesthetics. Leveraging efficient technology, we ensure high-volume production with consistent quality across every part.

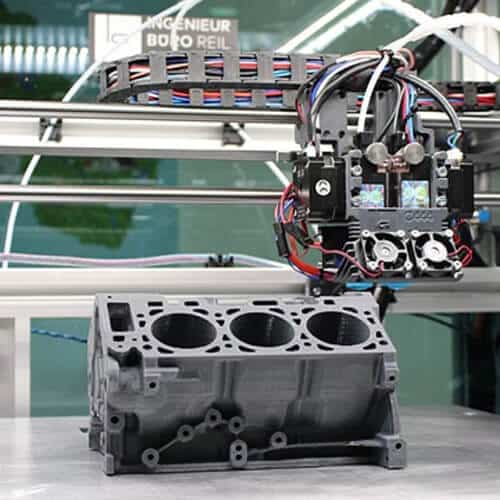

Impression 3D

DEK's 3D printing services can help you quickly turn your automotive prototyping ideas into reality, shorten the development cycle, and help designers and engineers iterate and test quickly and make timely adjustments.

We can provide over 50 certified materials to meet different customer needs. We can realize complex geometries, reduce design constraints, and customize the automotive components you need. We simplify the production process with flexible manufacturing that is cost-effective in automotive prototyping and low-volume part production.

Matériaux

Prototype automobile Options de matériaux

Aluminium

DEK machines custom automotive parts and prototypes using aluminum alloys AL6061, AL5052, AL7075, AL5083, and AL2024.

Laiton

Brass is a low-friction, corrosion-resistant alloy that DEK precision-machines to prototype critical automotive components.

Cuivre

DEK utilizes copper’s high conductivity to prototype essential automotive components like busbars and heat exchangers.

Acier

DEK machines durable custom automotive parts and prototypes using alloy steel, mild steel, and stainless steel.

Titane

We machine high-precision automotive prototypes and custom parts using Grade 1, Grade 2, and Grade 5 titanium.

Nylon (PA)

We machine durable automotive prototypes and custom parts using nylon to leverage its strength and abrasion resistance.

Acrylic (PMMA)

DEK machines lightweight, shatter-resistant automotive lighting components and clear parts using Acrylic (PMMA).

Silicone

Precision automotive prototypes are fabricated from silicone to produce heat-resistant seals, cover assemblies, etc.

Processus

Our Manufacturing Processus

Concept Prototype and CAD Digital Model

The automotive prototyping process begins with an initial presentation of design ideas based on market requirements using hand-drawn structural drawings, followed by the creation of a conceptual prototype using CAD (Computer Aided Design) software.

Concepts are then brought to life using clay models to realize the idea of a real object, helping automotive designers to better evaluate and optimize the iterative process within the team, customers, and stakeholders to ensure both functionality and aesthetics before final production.

Structure and Function Verification

Automotive engineers refer to this phase as the “mule phase,” during which they build a series of functional prototypes, primarily to validate the spatial fit of components and collect functional data.

This helps to assess structural dimensional reasonableness and ease of installation, and enables engineers to observe how prototype components work with the vehicle and other components, while examining design, materials, strength, tolerances, assembly, operating mechanisms and manufacturability, so that potential problems can be detected and solved in advance.

Engineering Testing and Pilot Production Run

Automotive prototypes undergo rigorous testing—covering aerodynamics, mechanics, and safety—to ensure they meet performance standards. Testing in extreme, real-world conditions allows engineers to quickly identify flaws and iterate designs to satisfy certification requirements.

Small-volume pilot production further optimizes the process by identifying assembly challenges early. This phase refines manufacturing workflows, ensuring that full-scale production is both cost-effective and reliable.

Pourquoi choisir Nos services

La production en une seule étape de prototypes de haute qualité vous permet d'économiser du temps et de l'argent.

Capacités d'ingénierie

Production rapide

Finitions de surface

Contrôle de la qualité

Assemblage de précision

Emballage et transport

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.

Envoyer l'appel d'offres 222

Revue et citation

Confirmer la commande

Production

QC

Livraison

Automotive Prototyping Service FAQ sur l'achat

Obtenir un devis précis Pour vos prochains projets

Que votre projet soit simple ou compliqué, qu'il s'agisse de métal ou de plastique, vous obtiendrez un devis précis dans les 6 heures.

Obtenir un devis aujourd'huiConnaissances of Automotive Prototyping

What is Automotive Prototyping?

Automotive prototyping entails creating the first sample (prototype) of a vehicle, part, component, or tool. Prototyping is one of the most vital steps between the initial sketch or design and the final product.

With the help of prototyping, manufacturers can check the functionality of a component, the proper materials, visualize its structure, check for errors, and, most importantly – test its safety.

If you want to know more about automotive prototyping, you can read le guide ultime du prototypage automobile ici.

Advantages of Automotive Prototyping

Risque réduit : Automotive prototypes reduce the risk of mass production by identifying design and functional defects as early as possible.

Économies de coûts : La résolution des problèmes au cours de la phase de prototypage garantit un processus de fabrication rentable.

Améliorer la qualité : Grâce à des tests itératifs et à des améliorations, le prototypage garantit que le produit final est esthétiquement plaisant et fonctionnel.

Communication améliorée : Le prototypage favorise une meilleure compréhension et une meilleure coordination entre les membres de l'équipe et les parties prenantes.

Applications of Automotive Prototyping

Lighting Systems: Optical prototyping is used to test and evaluate the shape, optical clarity, heat dissipation, and weather resistance of headlights, taillights, fog lights, and lamp housings.

Interior Systems: Prototyping was used to evaluate button layout, tactility, display placement and visibility to ensure easy and safe access for the driver.

Body Systems: Body panel prototypes are used to test the aerodynamic performance, structural strength and visual appearance of vehicles.

Power System: Engine prototypes test the fit of various components, the efficiency of the cooling system, and vibration and noise levels.