- Accueil

- Ressources

- What is Precision Grinding: Process, Types, and Techniques

What is Precision Grinding: Process, Types, and Techniques

Precision grinding is one of the most dependable ways to produce fit parts without error.

In my experience, it consistently delivers excellent results on strong materials like steel, titanium, and carbide. So, let me help you understand everything you need to know about this process.

Qu'est-ce que la rectification de précision ?

It is a machining process that I use for parts that need exact dimensions and a flawless finish. The goal is not just to remove material but to achieve a precise geometry and surface quality that other processes can’t do.

How Does It Work?

It works by using a rotating wheel covered with abrasive grains to remove material from a workpiece slowly. I carefully control the wheel speed, pressure, and feed rate to avoid damaging the part. I always apply coolant during grinding to avoid overheating, reduce friction, and clear away debris.

Types de rectification de précision

Rectification cylindrique

This type is for parts with round or curved surfaces, such as shafts, rods, and sleeves. The grinding wheel turns against the rotating workpiece to remove small amounts of material.

Meulage de surface

This one is to make flat surfaces, usually for metal parts, tools, and components in automotive and aerospace applications. The wheel moves across the surface, removing thin layers of material to create a fine finish.

Jig Grinding

I use jig grinding for finishing dies, molds, and fixtures with detailed shapes. The process uses a high-speed spindle and a fine grinding wheel to achieve precise holes, contours, and surface finishes.

Creep Feed Grinding

This process removes more material in one deep pass, similar to milling. I use it for hard alloys and parts that need heavy stock removal in less time.

Single and Double-Disc Grinding

Single-disc grinding is for one-sided precision finishing on flat or gently curved surfaces. For thin parts, double-disc grinding processes both sides at the same time, so it saves time and ensures consistent results.

Meulage sans centre

I like using precision centerless grinding to produce rods or tubes in large quantities. In this process, I don’t have to hold the part in place; it is supported by a blade and guided between the wheels.

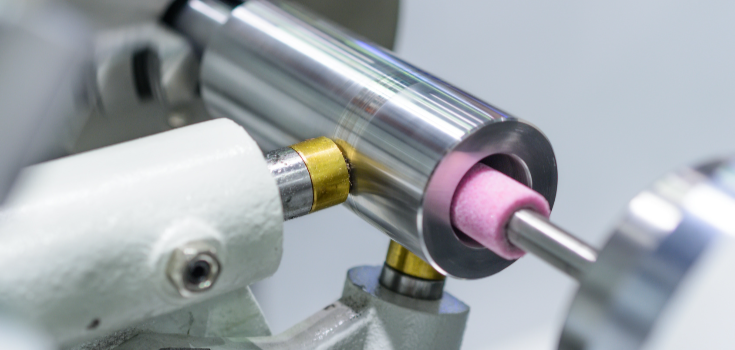

Internal Grinding/ Inner Diameter Grinding

I use internal grinding to finish holes or inner surfaces of parts such as bushings, bearings, and cylinders.

External Grinding/ Outer Diameter Grinding (OD)

I usually use external or OD grinding for finishing the outer surface of cylindrical parts like shafts, rollers, and tubes.

Superabrasive Grinding

For extremely hard materials like carbide, ceramics, or hardened steel, I use superabrasive wheels made from diamond or CBN for fast, precise cutting.

Thread Grinding

I usually use thread grinding for precise screw threads or threaded components.

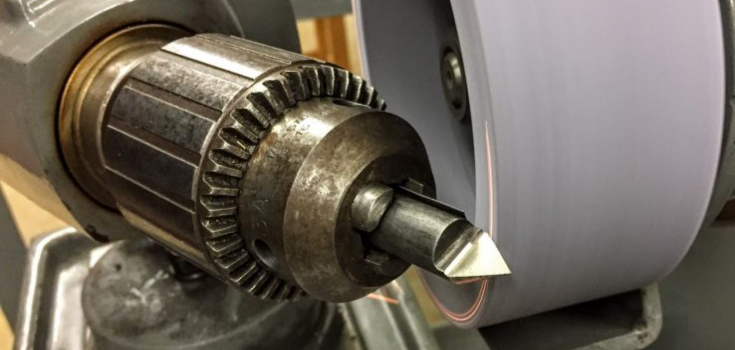

Tool and Cutter Grinding

I use this precision tool grinding to sharpen or shape cutting tools like drills and end mills.

Spindle Grinding

I use spindle grinding when a rotating shaft or spindle needs precise dimensions. This process lets me fine-tune both the diameter and alignment.

Techniques in the Grinding Process

Wet Grinding

I use wet grinding when I need to control heat and protect the part from damage. The coolant or lubricant helps reduce friction, keeps the temperature low, and washes away any debris that collects on the grinding wheel.

Dry Grinding

I use dry grinding when working with metals that react to fluids or change properties when exposed to moisture. It can cause the grinding wheel to wear out faster and generate more heat. It is useful for quick material removal when coolant can’t be used.

High-Speed Grinding

The wheel spins much faster than in standard setups, removing material quickly while keeping the surface accurate and smooth.

Ultra-Precision Grinding

This process finishes at the nanometer level using machines that tightly control temperature and vibration.

Rough Grinding

I usually do this before final finishing to get the part close to size before switching to a more precise method.

Blanchard Grinding

With its vertical spindle and rotating magnetic table, it can remove material from big parts fast. It is one of the best ways to achieve a flat, uniform surface on heavy steel plates or large components.

Electrochemical Grinding (ECG)

The wheel and an electrolyte work together to dissolve the material with very little heat. I like this method for tough or thin-walled parts.

Peel Grinding

I use a narrow wheel that follows a programmed path to create detailed shapes and fine profiles. It is perfect for small, intricate components, like in tool and die applications.

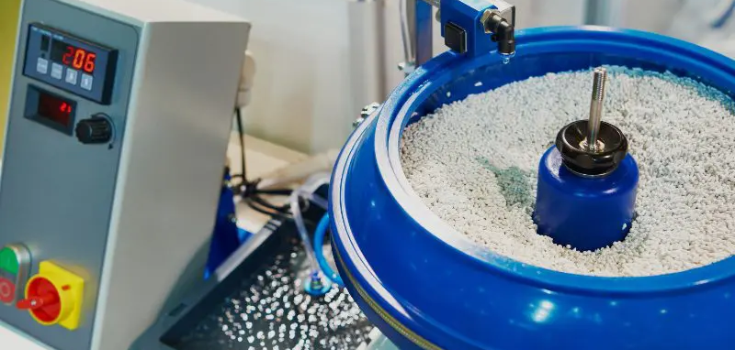

Vibratory Grinding

To deburr or polish small parts, I place the workpieces and abrasive media inside a vibrating container. The constant movement polishes the parts gently, leaving smooth, clean surfaces without removing too much material.

Cryogenic Grinding

Some materials, like plastics or rubber, are hard to grind because they soften with heat. By cooling them with liquid nitrogen, I make them brittle and easier to work with.

Materials Available for the Grinding Process

Métaux

Grinding works well on steel and aluminium. Steel provides toughness, while aluminum offers lightness.

Céramique

Ceramics like silicon carbide and porcelain are hard but brittle. It needs extra care when using controlled grinding speeds and special abrasives to shape them without causing cracks or chips.

Plastiques

Plastiques are soft and easy to shape. I prefer to use wet grinding for plastic materials to prevent heat damage.

Composites

Composites like carbon fiber and fibre de verre are strong but layered, making them challenging to grind. I use specialized tools and techniques to avoid damaging the fibers.

Caoutchouc

![]()

When grinding rubber parts like seals, rollers, or gaskets, I focus on smoothing out surface imperfections and making each part uniform.

Bois

Wood is smooth and easy to shape. I use fine abrasives to preserve the natural grain for furniture and cabinetry.

Verre

Glass is hard and fragile; it requires a steady hand and precise control to prevent cracking. I use grinding to shape or polish optical lenses, displays, and decorative items.

Stone

When I grind stone like granite or marble, I rely on diamond tools to cut, shape, and polish accurately. This technique is ideal for monuments, countertops, and architectural pieces.

Semi-conducteurs

![]()

Grinding semiconductors such as silicon helps me create ultra-flat, precise wafers for electronics. Every step must be controlled to maintain thickness, smoothness, and dimensional accuracy for sensors, chips, and circuit components.

Carbides

Tungsten carbide and similar materials are some of the hardest I work with. I use precision grinding and sharpening to cut tools and shape components for machining and drilling.

Hard Alloys

These alloys are used in aerospace and medical parts that need to resist heat, pressure, and wear.

Benefits of Precision Grinding Services

Precision grinding is one of the best ways to achieve accurate and high-quality finishes on metal parts. I use this process when a project requires tight tolerances and smooth surfaces. Whether I’m working with ferrous or non-ferrous materials, precision grinding lets me create consistent results even for complex geometries and small components.

This technique is highly adaptable, which is why it is ideal for different shapes and sizes. Precision grinding also helps control production costs and has little room for error. Compared to other finishing methods, it delivers better surface quality, higher efficiency, and greater reliability, making it a smart, next-generation machining solution.

Drawbacks of Precision Grinding

Precision grinding comes with a few challenges worth considering before starting a project. The process can be time-intensive, which increases production costs. I always assess whether such high precision is really needed or if standard machining methods like milling or turning can meet the specifications.

Another factor is the high initial cost of the equipment. Precision grinding machines are expensive, and it’s important to weigh whether the investment will bring enough long-term value to justify the expense.

To avoid issues about debris left on the part’s surface and contamination, I make sure each part is thoroughly cleaned and inspected before final delivery.

Applications of Grinding Services

Engine Components

I grind parts like camshafts, crankshafts, and cylinder liners to provide smooth operation and maximum efficiency.

Hydraulic Components

Pistons and rods require a very fine surface finish to maintain proper sealing and prevent fluid leaks.

Pièces pour l'aérospatiale

I grind turbine blades, landing gear, and other flight-critical components that need extreme accuracy.

Dispositifs médicaux

Surgical instruments, implants, and diagnostic components require exact dimensions and flawless finishes for safe performance.

Paliers

Ball and roller bearings are ground to obtain a smooth surface to minimize friction and extend service life.

Outils de coupe

Drills, end mills, and other machining tools rely on precise grinding to maintain sharp edges and consistent geometry.

Gear Manufacturing

Precision grinding ensures accurate tooth profiles and eliminates noise for an efficient gear performance.

Molds and Dies

I grind molds and dies to achieve tight tolerances and superior surface quality.

Alternatives to Precision Grinding

Reaming: I use reaming to refine or enlarge existing holes for smooth, accurate finishes.

Honing: This technique improves hole roundness, straightness, and surface finish using a reciprocating abrasive stone.

Lapping: I use lapping for ultra-precise work. An abrasive slurry removes tiny amounts of material to achieve tight tolerances.

Precision Grinding vs. Other Machining Methods

Fraisage

It is ideal for quickly removing large amounts of material, but when I need superior accuracy and a smoother surface, grinding performs better.

Tournage

This method works well for shaping cylindrical parts, yet grinding gives me finer finishes and tighter dimensional control, especially on harder materials.

EDM (usinage par décharge électrique)

EDM is excellent for complex shapes and tough metals, but it often leaves a rough surface. Grinding eliminates that issue by delivering a clean, smooth finish.

Découpe au laser

This is a fast and precise method, but it can create heat-affected zones that change material properties. Grinding avoids this problem by producing precision results without thermal damage.

Découpe au jet d'eau

This process works for many materials and thicknesses, but it can’t match the quality I achieve through precision grinding.

Tips for Grinding High-Quality Parts

In precision grinding industries, achieving high-precision parts depends on careful planning and strict grinding process quality control. I always start by selecting the right wheel for the material and finish, keeping it properly dressed for consistent accuracy. Managing wheel speed, feed rate, and coolant flow helps prevent overheating and ensures smooth, defect-free surfaces.

Regularly checking alignment, minimizing vibration, and maintaining a clean workspace also improve consistent results.

High Quality Precision CNC Grinding Services at DEK

DEK provides top-quality precision grinding services that guarantee parts will fit exact requirements. We use advanced CNC equipment to ensure that each component is accurate, robust, and cost-effective.

Share your project specifications, and we will manufacture precision-ground parts that will work dependably in your specific application. Request a quote aujourd'hui.

Conclusion

Precision grinding solutions allow me to achieve a level of accuracy and reliability that modern industries demand. By refining each material with care and control, I can produce parts that perform flawlessly. This process turns raw materials into dependable, high-precision components ready for aerospace, medical, and industrial use.