- Accueil

- Ressources

- Ébauches d'emboutissage de métaux : Types, techniques, applications

Metal Stamping Blanks: Types, Techniques, Applications

Metal stamping blanks are pieces of metal sheet used in manufacturing several metallic end products, including gadgets, household tools, automobile parts, etc. Due to their versatile nature and usefulness in several industries, they remain a crucial material in metal stamping processes.

This guide explains everything you need to know about metal stamping blanks, including their types, factors to consider when making a selection, application, and so on.

What are Metal Stamping Blanks?

Metal stamping blanks are pieces of metal sheet used in stamping operations. They exist in several shapes and sizes and are usually used as canvas materials for several stamping projects.

They are vital in metal stamping because they form the basis on which stamping techniques like punching, piercing, drawing, and coining are carried out.

In simple terms, metal stamping is a manufacturing process that involves using a piece of metal to create a desirable product, design, or shape. These products range from aerospace tools and equipment, automobile and medical equipment, household and office tools, and so on.

Types of Metal Stamping Blanks

There are several categories of metal stamping blanks depending on the type of material you need, for example, aluminum, brass, copper, and gold filled metal stamping blanks.

On the other hand, we have other categories based on shapes and specific project requirements.

Flat Metal Stamping Blanks

These are simple, thin leveled pieces of metal used for easy stamping designs. They are usually used for small manufacturing projects involving simple stamping tools and equipment.

You’ll most likely find them as rectangular, oval, square, and round metal stamping blanks. They are lightweight and used in making items like keychains, tags, etc.

Progressive Metal Stamping Blanks

These are blanks used in progressive die stamping, where several operations are carried out in a sequential order. They are most suitable for mass complex manufacturing processes requiring great accuracy and precision.

Transfer Metal Stamping Blanks

They are suitable for more complex production processes involving moving the materials from one station to the other. It is commonly used in producing complex structural parts like chassis parts, panels, shield covers, etc.

Common Techniques in Metal Stamping

There are several metal stamping techniques you could use depending on the specific projects and needs. Understanding these techniques will help maximize work effectiveness and efficiency in the whole manufacturing process.

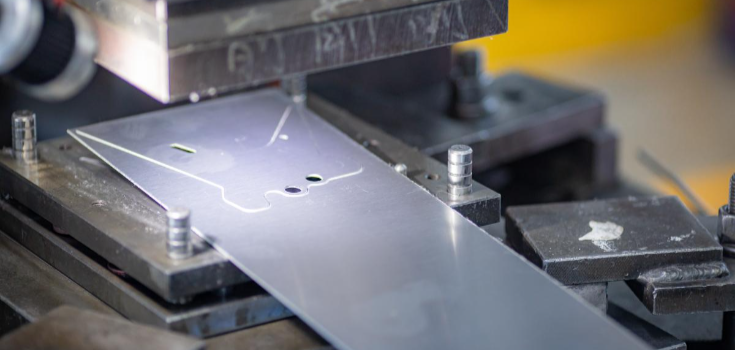

Blanking Process

This process involves cutting a desired size of blank or piece of metal from a larger metal piece. Usually, this is achieved using the stamping press and the die, where the press pushes the die onto the metal sheet until a blank is formed.

This process not only helps cut out the métal, but it does that with great precision, ensuring that the specified size and dimensions are achieved.

To achieve good results while using this method, you should take the following factors into consideration.

Type of material: The type of metal material used determines how it reacts when working with a stamping press. Materials like aluminum and copper might need different die materials during the blanking process.

Material Thickness: If you’re working with a strong, thick material, then you might need more complex machinery that can withstand great force and give a smoother blank.

Précision : The press must be properly set up, ensuring that the die and punch align and the cutting edges are sharp. All of these have an influence on the quality of the blank that’ll be generated.

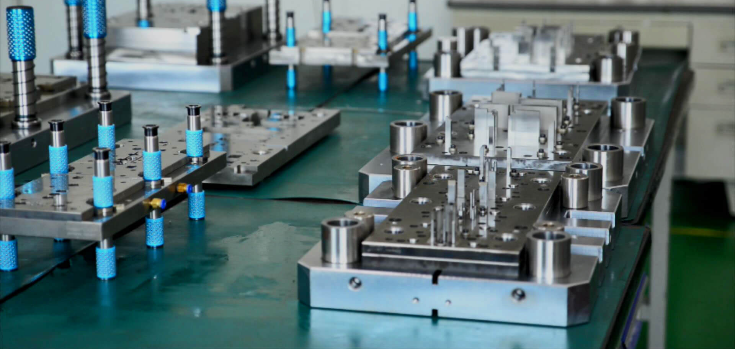

Progressive Die Stamping

In progressive die stamping, the metal sheet moves from one station to the other within a particular machine until the desired product is formed.

In every station, stamping operations like punching, coining, drawing, etc., are carried out until a specified product, design, or shape is generated.

Progressive die stamping is a specialized and highly efficient method for bulk production. It also helps ensure that production is achieved at a high-speed rate with minimal material waste.

Transfer Die Stamping

Unlike the progressive technique, where the metal parts move sequentially from one station to the other, in transfer die stamping, the metal parts are mechanically moved through automated systems across different stations, with each station performing various operations.

Transfer die stamping is more suitable for complex metal parts that cannot withstand being connected as a metal strip. As such, they need to be transferred individually to each station until the final product is obtained.

You should use this technique over others when a more complex and larger part that cannot be done with progressive die stamping is involved.

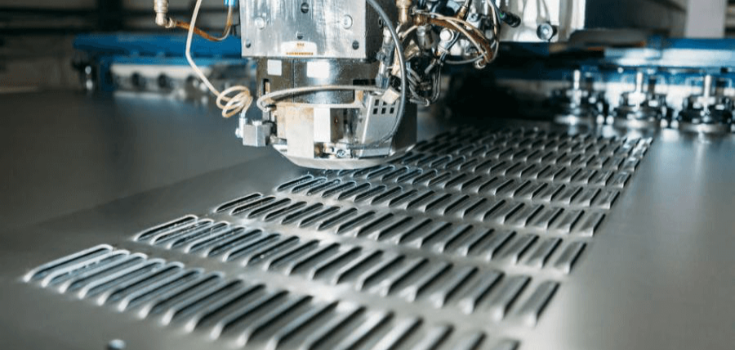

Fine Blanking

Fine blanking uses a special mechanical press to ensure that metal parts are smoothly cut out. With this technique, the metal pieces to be cut are firmly gripped by the stamping press and die to avoid movement until a fine, clean material is obtained.

Usually, the materials generated here are free from burrs compared to the traditional blanking process. Fine blanking is important in producing high-precision blanks because:

- It produces material with smooth edges, eliminating the need for other finishing touches.

- It can generate material with unique shapes and features that might not be easily obtained with other stamping techniques.

- It reduces material deformation due to cutting as much as possible.

- It improves efficiency since it combines multiple operations like punching, finishing, and blanking into one whole step.

Applications of Metal Stamping Blanks

Metal stamping blanks are essential to many industries. Below are some areas you’ll find them useful.

Industrie automobile

They are used to create several car parts, including the trunk lids, roof panels, chassis components, etc.

They are also used to form functional precision-based components like connectors, which must align with the required specification for utmost performance.

Industrie électronique

Some components of our gadgets, like smartphones and laptop tops, are also manufactured using stamping blanks. These include phone covers, enclosures, etc.

Power-inclined parts like connectors and terminals are derived from blanks to ensure they resist heat.

Industrie aérospatiale

Several parts of the airplane structure are designed with high-precision metal blanks, including the panels, brackets, stringers, etc., to ensure adequate safety and performance.

Many of the engine parts, like spacers, heat shields, and fasteners, are produced with blanks.

Industrie médicale

Surgical equipment like forceps, blades, and clamps is manufactured with blanks. Fine blanking technique is specifically used to ensure the item comes out with smooth edges.

They are also useful in making implants, prosthetic parts, trays, cases, etc.

Advantages of Using Metal Stamping Blanks

Cost-effective and Highly Efficient

Since metal stamping operations are automated, you can produce massive quantities within a shorter time frame and at high speed. Beyond that, you can generate high-quality products while also minimizing costs.

Industries like electronics and automotive find that maximizing this efficiency in manufacturing large volumes of metal parts is important.

Versatile in Usage

Several metal materials, including aluminium, copper, brass, etc., are used for stamping operations, which makes them suitable for use within many industries.

Depending on your specific needs, you’ll always find stamping blanks that suit. For example, copper is widely used in electronics, while stainless steel is used for medical equipment.

Ensures High Precision

Metal stamping blanks are made with high precision, which makes them applicable for use in some industries.

You can rest assured that you can generate metal parts that meet a unique specification with a stamping technique. An industry like medicine requires high-precision tools to ensure that items work effectively.

Integrates Several Operations into a Whole

Metal stamping blanks are also manufactured through an integrative manufacturing process. Blanking, punching, bending, coining, and every other process happen in a roll, thereby simplifying the processes into one. With this, time, effort, and costs are saved.

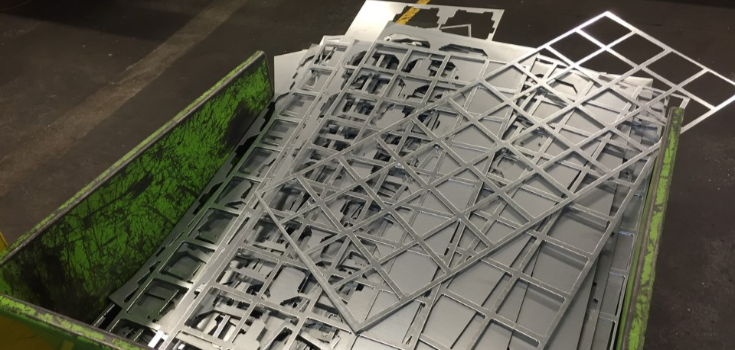

Eliminate Material Wastage

Through the use of advanced stamping techniques, metal materials are being used as much as possible to eliminate waste while also generating high volumes. Techniques like progressive die stamping maximize the use of metal sheets, help reduce cost, and produce more output.

Highly Scalable and Customizable

Production of metal stamping blanks is highly scalable. Depending on your requirements or your customers' own, you can easily increase your production volume without sabotaging the quality. Also, you can customize the stamping tools and machine to get unique designs and characters.

Eliminate Deformity and Improve Structural Integrity

Even though metal stamping involves several operations that put the materials through stress, the metal sheets still maintain smoother and cleaner cuts.

Main Considerations When Choosing Metal Stamping Blanks

Selecting accurate stamping blanks involves considering some points. By choosing the suitable one, you will be able to ensure efficiency and effectiveness and generate quality products that meet your needs. Here are the key factors to consider.

Matériau métallique

The material of the stamping blank could be aluminum, copper, stainless steel, or gold. Let's look at each of them, their properties, and applications.

Aluminum Properties

- They are lightweight

- Good conductor of heat

- They can withstand corrosion

- They are also highly malleable, thus can be formed into shape easily

Aluminum Applications

- Useful in aerospace, electronics, automotive, and packaging industries.

Stainless Steel Properties

- It can resist corrosion.

- Has good heat resistance.

- It has a shiny, fine appearance.

Applications en acier inoxydable

- Essential in the medical field for manufacturing equipment like blades and forceps.

- Vital in the food production and automotive industry.

Copper Properties

- Great conductors of heat and electricity.

- Highly resistant to corrosion.

Copper Applications

- Essential in the electrical industry for making wires and other components.

- Useful in the automotive industry.

Gold Properties

- They are highly malleable and thus can easily form a desired shape.

- It can also withstand corrosion.

- High conductor of electricity.

Gold Applications

- Gold-filled stamping blanks are useful in jewelry creation.

- Vital in the electrical industry since they are excellent electrical conductors.

Thickness and Dimensional Tolerances

The thickness of the blank also determines how strong and durable the final product is. However, you could expect a more rigorous stamping process.

Also, for industries like electronics and medicine, where high precision is vital, choosing blanks with tight tolerances is crucial.

Supplier for the Blanks

You might also want to check the kind of supplier you use. Look out for their years of experience, consistency with the quality of materials usually produced, and ability to deliver on time and regularly, and so on.

Coût

Another factor to consider when choosing your metal stamping blanks is the cost. Depending on your choice and specific project needs, you’ll find several materials with varying costs.

While considering cost, it is good to be on the lookout for quality. The cost of processing the blank is another point to check, as the thickness of the type of material chosen may influence production cost.

Quality of the Metal

For maximum results, it is best to choose only quality blanks, regardless of the materials they are made of. Good quality blanks help ensure that stamping operations are carried out smoothly and, more so, a high-quality final product is derived.

Look out for characteristics like the absence of impurities, surface finish of the blank, level of purity, etc.

Regulatory Compliance and Certifications

Some particular industries usually require certifications and compliance policies for the materials of the stamping blanks. If you are in the medical or automotive industry, then you need to be aware of the specific regulations governing the use of materials within your field.

Conclusion

The importance of metal stamping blanks in several fields cannot be overlooked. Selecting the right blank that meets the key considerations explained above and, more so, your specific project need is, however, important.

If you need assistance in selecting quality material that guarantees high product precision for your next project, do reach out to DEK. We are always available to provide accurate guidance and expertise that meets your unique project requirements.

FAQ

How do I choose the suitable metal stamping blank?

To choose suitable metal stamping blanks, consider factors like the type of metal, quality of the metal, thickness and dimensional tolerances, regulatory compliance policies and certifications regarding the use of blanks within your field, metal purity, and every other specific requirement of your project.

What materials are used for metal stamping blanks?

Several materials, including copper, aluminum, brass, stainless steel, carbon, etc, are used for metal stamping blanks.