- Accueil

- Ressources

- Copper Stamping

Copper Stamping: Properties, Processes, and Applications

If you’re thinking about using copper for your project, you might want to learn about copper stamping. This process helps shape copper into parts you need quickly and with high precision.

In this guide, you’ll learn what copper is, how stamping works, and what tools and materials you need. I’ll also walk you through the steps, show you different stamping techniques, and help you choose the right type of copper. Let’s get started.

Understanding Copper Stamping

Copper is a reddish-orange metal that’s been used for thousands of years. It’s soft, easy to shape, and conducts electricity and heat very well.

Copper metal stamping is a way to shape flat copper sheets or coils into parts or designs using pressure. You use a stamping press and die to cut, bend, or press the copper into the shape you want.

Properties of Copper Metal

Copper has some important qualities that make it a great choice for stamping, such as the following:

Electrical and Heat Conductivity: Copper carries electricity and heat very well, which is important for electrical parts.

Malleable: You can bend and form copper into detailed shapes without it breaking.

Resistant to Rust: Copper forms a natural layer that protects it from rust and damage.

Ductile: Copper can handle a lot of bending and stretching during stamping without cracking.

Choosing the Right Copper Material for Your Project

Here are the factors you need to think about when choosing the right copper for your stamping project:

- Do you need copper that carries electricity well, is strong, or resists rust? Choose based on what matters most.

- Will the copper be around moisture or chemicals? If so, choose a type that won’t corrode easily.

- Think about how the copper will behave during stamping, and if you’ll need to solder or weld it later. Make sure it works well for all the steps.

Copper Stamping Processes

There are different ways to stamp copper, depending on what kind of part you need. Here are four common techniques you might use:

Fine Blanking for Precision Parts

This method is used when you need very precise parts with smooth edges. A special press cuts the copper cleanly with a lot of force, so the part comes out sharp and exact.

Piercing

Piercing means making holes or slots in a copper sheet. You usually do this with a punch press. The punch pushes down on the copper and presses it into a die, which makes a clean hole.

Coining and Embossing

These techniques add designs to the surface of the copper. Coining uses high pressure to press in sharp, detailed patterns. Embossing pushes the metal from behind to make raised shapes or textures.

Bending and Forming

Pliage is when you fold or curve a copper sheet along a straight line. You use it to make shapes like brackets, panels, or covers. A machine called a press brake pushes the copper over a die to give it the angle or curve you need.

Forming means shaping the copper sheet into more complex 3D parts. You can stretch, press, or shape the copper into things like cups, trays, or other strong parts used in different products.

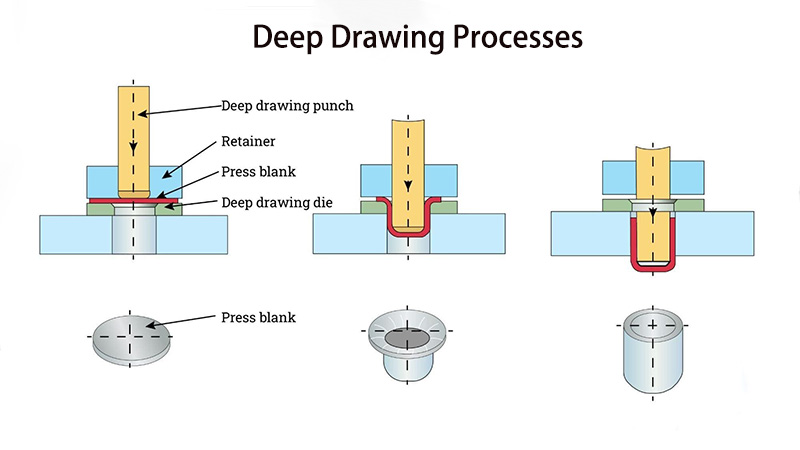

Deep Draw Stamping

If you need deep, hollow shapes, this is the technique you need. A punch pulls the flat copper sheet into a die, stretching it into the shape you want.

How to Stamp Copper?

This is the step-by-step guide on how to do copper stamping:

Material Selection and Preparation

First, check the copper sheet. Look at its thickness, surface, and quality. Make sure it’s clean and flat. Any dirt or damage can affect how well the stamping turns out.

Stamping Process Stages

Use a stamping press to press the copper into shape with a die. The press uses just the right amount of force to bend or cut the copper. For complex parts, you might need to stamp the copper more than once and heat it in between to keep it soft and flexible.

Quality Control and Inspection

After stamping, check each part carefully. Use measuring tools (like a CMM) to make sure everything is the right size and shape. This helps you catch any mistakes before moving on.

Tooling for Copper Stamping

The tools you use in copper stamping affect how well and how fast you can make your parts.

Designing the Right Die for Copper Stamping

When you design a die (the part that shapes the copper), you need to keep these things in mind:

- Make sure the die matches the part you want to create.

- Leave enough space between the die and the punch so the copper can move without causing too much friction or damage.

- Choose materials that can handle pressure and won’t wear out quickly.

- Design the die so it’s easy to clean, adjust, or repair when needed.

Common Materials Used in Stamping Tools

Below are some of the common materials you can use in stamping tools:

Acier à outils : Very strong and hard; great for long-lasting, sharp tools.

Cemented Carbide: Super hard and wear-resistant, perfect for tough jobs.

Steel-Bonded Carbide: A mix of steel and carbide, strong and tough.

Aluminum Bronze: Works well with copper and helps stop the metal from sticking to the die.

Polymers (Plastic-like Materials): Sometimes used when you need lighter tools and don’t mind if they wear out faster.

Copper Metal Stamping Finishes

After stamping, you can finish your copper parts in different ways to make them look better and last longer, and these are some of the common finishing options:

Polished: Gives the copper a shiny, smooth surface.

Brushed: Creates a dull, matte look with a textured feel.

Nickel-Plated: Adds a layer of nickel to protect against rust and wear.

Tin-Plated: Makes it easier to solder the copper.

Copper Grades Used for Metal Stamping

In copper stamping, not all copper is the same. Each type has different strengths and uses. Here’s what you should know:

Pure Copper (C11000)

This is the purest form of copper. It’s excellent at carrying electricity and heat. If you’re working on something electrical, this is the best choice.

Bronze Copper Alloys

When you need something stronger and more resistant to rust, go with bronze. It works well in tough environments like the ocean or industrial machines.

Brass Copper Alloys

Brass is easier to shape and has a nice look. It’s great for parts that need to look good and handle wear, like fittings or decorations.

Beryllium Copper (BeCu)

This type is strong and flexible. It’s not magnetic and can handle stress well. You might use it for aerospace parts or tiny electrical connectors.

Maillechort

Even though it sounds like it has silver, it doesn’t. It’s an alloy of copper, nickel, and sometimes zinc. It’s strong, shiny, and resists rust, which makes it perfect for decorative parts.

Applications of Copper Metal Stamping

Here’s how copper stamping can help in different industries:

Industrie électronique

Copper stamping helps you make parts that need to carry electricity well and work reliably. You can use it for connectors and terminals, heat sinks, switches and relays, and circuit boards.

Automobile

You need copper for car parts like terminals, connectors, and contactors. It helps your vehicle’s electrical system work properly and adds to the overall reliability.

Dispositifs médicaux

You’ll find copper-stamped parts in things like surgical tools and diagnostic machines. Plus, copper’s natural ability to fight bacteria makes it even more useful here.

Aérospatiale et défense

When you’re flying high or working with defense systems, there’s no room for failure. Copper-stamped parts are used in aircraft wiring, communication systems, and radar equipment.

Renewable Energy Systems

As we move toward cleaner energy, copper plays a big role. You’ll see it in solar panels and wind turbines, where it helps transfer energy efficiently and stands up to tough weather.

Conclusion

Now that you’ve learned the basics of copper stamping, you should have a better idea if it’s right for your project. It’s a great way to make strong, detailed parts, especially if you need them to carry electricity or resist rust. Just remember to choose the right type of copper, use the right tools, and check the quality of your parts.

If you need copper stamping services, let DEK handle it for you. We offer precise, fast, and reliable copper stamping services tailored to your needs. Whether you need prototypes or full production runs, we’re here to help. Contactez nous today to get a free quote and expert support.