- Accueil

- Ressources

- Aerospace Grade Aluminum: Best for High Performance Needs

Aerospace Grade Aluminum: Best for High Performance Needs

When building an aircraft, you need materials that are strong, lightweight, and reliable. That’s why aerospace grade aluminum is used in many parts of a plane. It handles high stress, changing temperatures, and heavy loads while keeping the aircraft light.

In this article, you’ll understand what aerospace aluminum is, why it is important, and how it’s used in different parts of an aircraft to improve performance and safety.

What is Aerospace Grade Aluminum?

Aerospace grade aluminum is a special group of aluminum alloys made for strong, lightweight, and high-performance applications. This is built to handle extreme conditions and even temperatures.

It’s widely used in aircraft, spacecraft, and other demanding projects because it stays strong without adding extra weight.

Properties of Aerospace-Grade Aluminum

Here are the important properties that make aerospace-grade aluminum stand out:

Exceptional Strength-to-Weight Ratio

One of the best things about aerospace-grade aluminum is how strong it is for how light it feels. This is important for anything that needs to be fast, efficient, and durable.

High Corrosion Resistance

Aerospace-grade aluminum resists rust and damage, even in moisture and harsh conditions. Adding zinc, magnesium, and copper makes it even stronger, which is important for modern aircraft wings and fuselages.

Thermal and Electrical Conductivity

Aluminium carries heat and electricity very well. In aerospace work, you use it for cooling systems, heat exchangers, and electrical wiring because it moves heat and power safely and efficiently.

Excellente résistance à la fatigue

Aircraft parts go through a lot of stress, from takeoff to landing. Aerospace-grade aluminum can handle this repeated pressure without cracking or breaking. Its fatigue resistance helps keep planes and other vehicles safe and reduces the need for constant repairs.

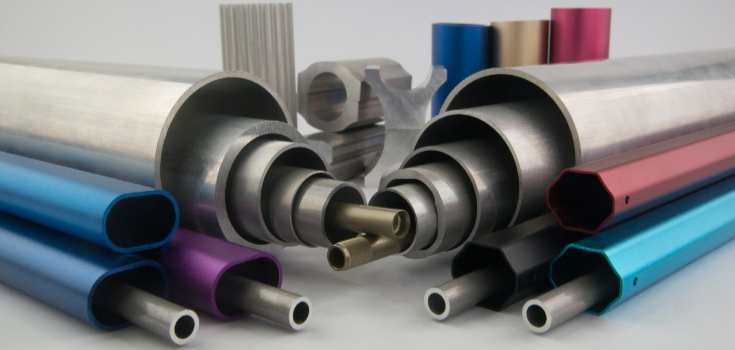

Malleability and Machinability

Aerospace-grade aluminum is easy to shape, cut, and machine into detailed, complex parts. You can use methods like extrusion, forging, and rolling to create custom pieces with tight measurements.

Recyclabilité

Sustainability matters, and aerospace-grade aluminum is a good, eco-friendly choice. You can recycle it many times without losing quality. It also saves energy, using only about 5% of what it takes to make new aluminum.

Commonly Used Aluminum Alloys in Aerospace

Aerospace uses different aluminum alloys, and these are the most commonly used ones:

2024 Aluminum Alloy

This one is the most popular alloy in aerospace. It’s very strong and resists fatigue well. It can hold up under repeated stress. You’ll mostly find it in sheet form for wings and fuselages.

2014 Aluminum Alloy

This alloy is strong and tough, but doesn’t resist rust as well. That’s why it’s often used inside the aircraft structure. It’s also good for arc welding.

5052 Aluminum Alloy

A non-heat-treatable alloy with great strength and flexibility. It’s easy to shape and very resistant to corrosion, making it useful for many aerospace parts.

Alliage d'aluminium 6061

It’s strong, easy to machine, and simple to weld, which makes it perfect for parts like wings and fuselages. You’ll often see this in light aircraft.

7050 Aluminum Alloy

Known for its high strength and excellent resistance to rust and cracking. It’s often used in wings skins, fuselages, and especially in military planes because it holds up well in tough conditions.

7068 Aluminum Alloy

One of the strongest aluminum alloys available with low weight. It’s perfect for aircraft that need to handle extreme pressure, often used in military aircraft as well.

7075 Aluminum Alloy

As strong as steel because of its high zinc content. It has great fatigue resistance, and it is easy to machine. It was widely used in World War II planes and is still used in some military aircraft today.

Less Common Aluminum Alloy Used in Aerospace

Some aluminum alloys aren’t as popular but are still very important in aerospace projects. Here are a few you should know:

2219 Aluminum Alloy

This alloy is good for welding, and it keeps its strength even at high temperatures. It was used in the fuel tank of the first space shuttle, Columbia.

6063 Aluminum Alloy

Often chosen for its clean and smooth look rather than just strength. It’s used for detailed parts and is also strong with good resistance to cracking.

7475 Aluminum Alloy

This alloy is very strong and sometimes found in fuselage bulkheads on large aircraft, helping the structure stay solid under pressure.

In the next few years, the need for aerospace aluminum is expected to double. This is because new materials like aluminum-lithium alloys are being made to help aircraft become lighter and work better.

Compatibility with Advanced Manufacturing Techniques

The aerospace industry is continuously evolving, and new methods of making parts are developing. Aerospace-grade aluminum works well with modern methods like 3D printing. This makes it easier for you to create strong, lightweight parts with complex parts that are hard to make using the old manufacturing techniques.

Benefits of Aerospace-Grade Aluminum

Here are some of the useful benefits of aerospace-grade aluminum:

Fuel Efficiency

Its lightweight design means your aircraft uses less fuel, lowering costs and reducing harm to the environment.

Maintenance and Longevity

It's built to last and resist rust, keeping your parts working longer with less maintenance.

Versatility in Design

It's easy to shape, cut, and weld into complex designs, so it is simple to make custom parts that match your needs.

Application of Aerospace-Grade Aluminum in Aircraft

Here’s a list of where you can usually find aerospace-grade aluminum in aircraft:

Aircraft Wings and Fuselage

The fuselage, which is the main body of the airplane, and the wings are the two most important parts that hold the aircraft together. These parts need to be strong and lightweight. That’s why aerospace-grade aluminum is often used. It can handle the stress of flying while keeping the aircraft light, which also helps save fuel.

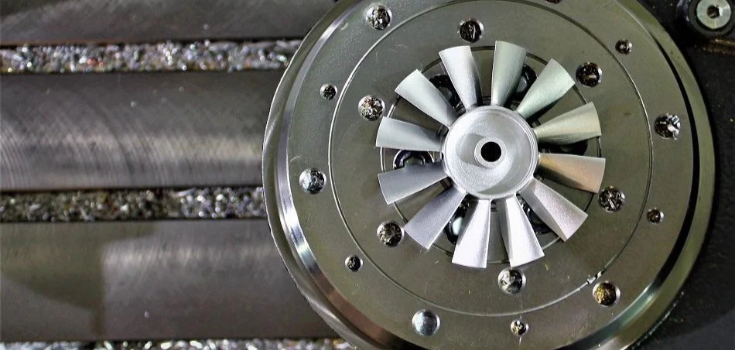

Aircraft Engines

Engines are not only made of steel or titane, but aluminum is also important here. Parts like fan blades and casings use aluminum alloys. They’re lighter, which makes the engine work better and use less fuel.

Landing Gear

The landing gear takes a lot of force during takeoff and landing. Aerospace-grade aluminum is strong enough to handle this.

Its high corrosion resistance makes the landing gear stay strong and reliable, even in tough weather conditions.

Interior Components

Inside the aircraft, aluminum is used for things like seat frames, overhead bins, and some cockpit parts. Because of its light quality, it helps lower the total weight of the plane, which improves fuel use.

And, it doesn’t rust easily, so these parts stay in good shape for years.

Electrical Systems

Aerospace-grade aluminum isn’t just used for big parts of the aircraft. It’s also used in electrical systems. It is a great conductor, which makes it perfect for wires and other electrical parts, helping the systems run smoothly and reliably.

Challenges and Solutions When Using Aerospace-Grade Aluminum

While aerospace-grade aluminum is a great material and is widely used, it comes with some challenges. Here’s what you might face and how to manage them:

Fatigue and Fracture

Aerospace aluminum parts deal with constant stress during flight, which can cause them to weaken and crack over time. To fix this, you can improve the design to spread out the stress and use traitements thermiques and special alloy mixes to make the material tougher and more resistant to damage.

Coût

Aerospace-grade aluminum, like 7075 and 2024, is more expensive than regular aluminum because it uses costly materials and strict production methods. To lower costs, you can use smart manufacturing techniques that reduce waste, improve efficiency, and use precise machines to speed up work and cut down on labor expenses.

Considérations environnementales

Producing aerospace aluminum uses a lot of energy and affects the environment through mining and emissions. To reduce this, you can recycle aluminum from old aircraft and scrap parts, which saves energy and helps cut down waste.

Conclusion

Now you know why aerospace-grade aluminum is trusted in aviation. It’s strong, lightweight, and can handle tough conditions. You’ve learned the different types and how each one helps keep aircraft safe, efficient, and long-lasting.

Au DEK, we manufacture high quality custom aerospace parts using different materials. We always have aerospace grade aluminum and other high performance materials available to use for any projects you may have. Contact us now and get a free quote!