- Accueil

- Ressources

- 7 Tips for CNC Machining Complex Parts

7 Tips for CNC Machining Complex Parts

CNC machining complex parts needed a blend of precision, experience, and thoughtful design. Everything, including hole placement, tool reach, and even wall thickness, can affect smooth operation and failure of the component.

This article offers practical insights that are useful for getting consistent and precise results in very complicated machining projects. You have learned that speed alone cannot yield better cuts. It requires planning in each phase of setup and finishing.

What is CNC Machining Complex Parts?

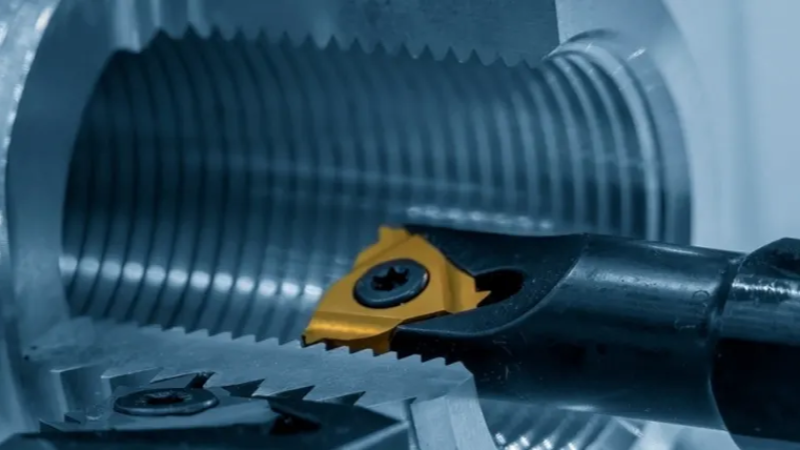

CNC machining complex parts means manufacturing the kind of components with complex geometries, several surfaces, and tight margins. These pieces are typical in aerospace, automotive, and medical applications, where the clarity of performance is critical.

For most parts, machining complex parts needed advanced milling and turning techniques and some multi-axis setups. In such a case, continuous cutting from different directions is improved for both efficiency and accuracy.

CNC machining small parts proves even more difficult. The smaller the part, the more it increases the effects of vibrations, temperature changes, and the wear on the tool. That is why DEK depends heavily on optimizing processes and simulation tools to guarantee dimensional stability at each stage.

Best Tips for CNC Machining Complex Parts

Plan Hole Placement

Accurate hole positioning makes Usinage CNC easy for creating the most complicated parts. It always checks the distance between holes and edges to avoid material distortion or tool deflection. Preserving the accuracy and strength of holes refers to their positioning well away from thin walls or corners.

In working with groups of different hole sizes, the entire group depends on their depth and diameter. Such a practice reduces the number of tool changes and keeps stable machining conditions. First, a small pilot hole is drilled into depth by step drilling before enlarging it, retaining precision, and taking care of chip buildup for deep holes.

Here is what works best:

- On Axis Holes should be as small as 1 mm.

- Side holes are somewhat larger.

- Avoid the group of holes too close to each other.

- Simulating toolpaths before final machining for clearance issues.

Manage Deep Features

Machining deep gaps or slots, or pockets, proves to be challenging. These flexion or vibrating tools affect the surface finish and accuracy. The choice always falls on the possible shortest tool that reaches the required depth to keep the hardness.

To maximize tool life and simultaneously reduce cutting forces, successive cuts should be given rather than cutting the full depth in one single pass. In turn, this allows for coolant to reach those deep areas for temperature control and clearing chips.

Those are the parameters for optimum performance:

- Keep the depths up to six times the slot width.

- Have at least 0.5 mm of wall thickness along the length outside the deep cuts.

- Avoid deep but narrow grooves because these induce vibration.

Design Better Threads and Inserts

Threads will often say how good a component is going to perform in the construction. The first thing is always to use standard thread sizes since they facilitate tooling while reducing errors. When special threading is needed, thread milling gives an edge in consistently controlled results.

Tap is effectively reliable on soft metals like aluminum, but lubrication must be put in place to avoid galling. We also suggest ample wall thickness on the threads to prevent cracking. Threading similar threads together reduces tool substitution and machining time.

- Helical inserts increase durability.

- Key-locking insert for parts in high-stress positions.

- Thread milling tools for better precision in hard materials.

Keep Text Minimal and Functional

Placing text of any form or logos on CNC bits is eye candy. Complex designs can slow down production speed and damage tiny tools. They are not fully engineered for such complexity. Arial or Helvetica are clear and straightforward fonts to engrave and are not easy to read.

Engraving depth should be maintained within the range of 0.2-0.5mm for optimal visibility. Shallower text saves time and reduces tool wear costs. Surface engraving is more effective than deep cutting for part identification purposes.

- Adequate letter spacing to prevent tool overlap.

- Large letters for small parts.

- Minimal ornamental features for quicker processing.

Add Proper Radii to Corners

These inside corners are all potential locations for defects to start cracking. Such corners should be designed with a radius equal to or slightly larger than that of the cutter. So, they do not leave uncut material and plastic stress on the tool.

Using the same radii for similar features improves programming and provides for smoother transitions. Whenever sharp corners are unavoidable, EDM finishing should be considered. The accuracy can be maintained without compromising the strength of the parts.

Consider Tool Access Early

Before machining starts, I visualize tool accessibility for each and every critical feature. Planning this out well in advance prevents interference, reduces errors, and collisions caused by tools. Occasionally, it just takes a little modification. Such as widening those angles or adjusting the pocket depth, to improve access dramatically.

It is quite common to examine more than one approach to accessing a complex part by tool. Simulation software is then employed to ensure toolpath verification and optimized multi-axis positioning. It is also good practice to break very challenging areas into shallower cuts to maintain good precision.

Not to mention, the importance of access to tool availability becomes higher when CNC machining very small parts. Compact tools commonly have very limited flexibility. For this reason, Access planning can make or break the final result.

Optimize Fixturing for Stability and Support

A strong fixture is the root of accurate machining. Every component should be retained solidly to maintain alignment and stability. Fixture points are planned earlier during the design phase to ensure flat surface clamping.

Non-uniform forces may cause distortion for thin-walled areas, especially under machining conditions of lightweight materials. DEK uses vacuum fixtures in combination with soft jaws to avoid but still clamp perfectly, without deforming delicate parts.

A set of practices is to be complied with, which includes:

- Making fixtures accessible to the entire tool path.

- Even distribution of clamping pressure.

- Fast prototype changes using modular fixtures.

Conclusion

CNC machining complex parts requires experience, consistency, and careful preparation by applying these strategies, from proper hole placement to optimized fixturing. DEK has achieved greater precision and reliability in even the most demanding projects.

Au DEK, we combine advanced technology with hands-on expertise in milling, turning, and small-part CNC machining. Suppose you are ready to bring your next complex design to life with accuracy and efficiency. Our team is here to support you every step of the way.