Metal 3D Printing Service

Les pièces sont imprimées à partir de fichiers de conception 3D individuels, ce qui permet de les personnaliser tant sur le plan fonctionnel qu'esthétique, sans coûts d'outillage élevés. L'impression 3D métal est recommandée pour les volumes faibles à moyens pour lesquels la personnalisation, le poids et le délai de livraison sont nécessaires.

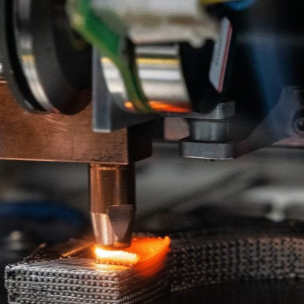

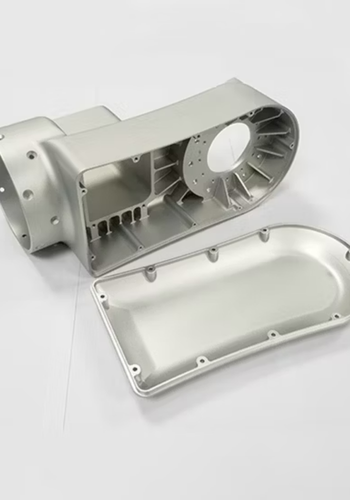

DEK provides comprehensive metal 3D printing services using advanced powder bed fusion technology and high-performance alloys like aluminum and titanium. Unlike many competitors, DEK integrates additive and subtractive manufacturing, in-house finishing, and ISO-compliant quality control. Our engineering expertise ensures optimized designs, faster turnaround, and cost-effective, production-ready parts.

introduction

High-Precision Impression 3D de métaux

DEK offers precision metal 3D printing services using advanced powder bed fusion technology, delivering complex, lightweight, and fully functional parts with integrated finishing and ISO-certified quality assurance.

Our facility is equipped with advanced metal printers capable of working with materials like aluminum, titanium, stainless steel, and other performance alloys. From concept to final part, we support customers through the full process, including design optimization, support structure planning, printing, post-processing, and quality inspection. Whether for prototypes or small-to-medium production runs, DEK ensures each part meets industry standards and functional requirements. In addition to printing, DEK offers integrated post-processing services, such as heat treatment, CNC machining, and surface finishing, all performed under strict ISO-certified quality control. Our team provides guidance on design, helping clients reduce material use, improve performance, and shorten production time.

By using both 3D printing and machining, we create high-quality metal parts faster, at lower cost, and with reliable results for industries like aerospace, medical, and automotive.

- Advanced PBF equipment

- Wide material selection

- Integrated finishing solutions

- ISO-certified processes

- Expert design support

- Fast project turnaround

Matériaux for Metal 3D Printing

Métaux

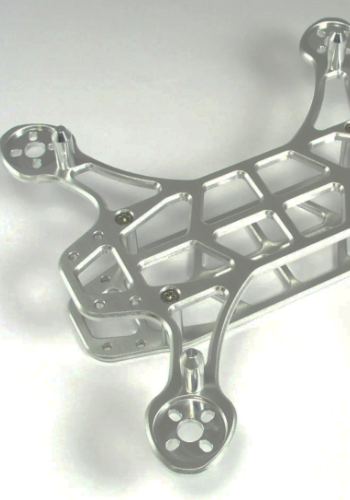

Aluminium

Aluminum is a lightweight, corrosion-resistant metal widely used in metal 3D printing for its excellent thermal conductivity and ease of machining. It is commonly used in aerospace, automotive, and consumer industries where weight reduction is critical.

DEK offers precise aluminum metal 3D printing services that produce parts like housings, brackets, and heat exchangers. Our technology ensures tight tolerances, smooth finishes, and quick turnaround times, making aluminum ideal for both prototypes and production parts.

Alliage

AL6061, AL6063, AL5083, AL5052, etc.

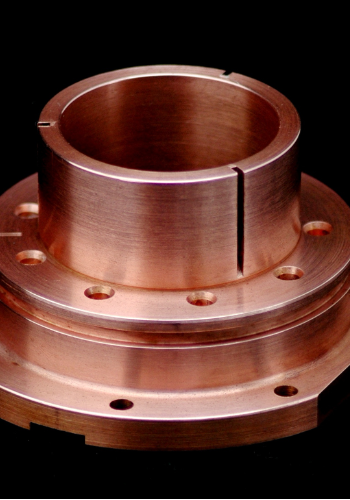

Cuivre

Copper is valued for its exceptional electrical and thermal conductivity, corrosion resistance, and machinability. It is widely used in electrical components, heat exchangers, and RF devices.

We offer precision copper metal 3D printing services that create intricate, conductive parts such as inductors and heat sinks. Our metal 3D printing ensures dimensional accuracy, smooth finishes, and consistent material performance, making copper ideal for both functional prototypes and end-use components in high-performance applications.

Alliage

Cuivre C101, C110, etc.

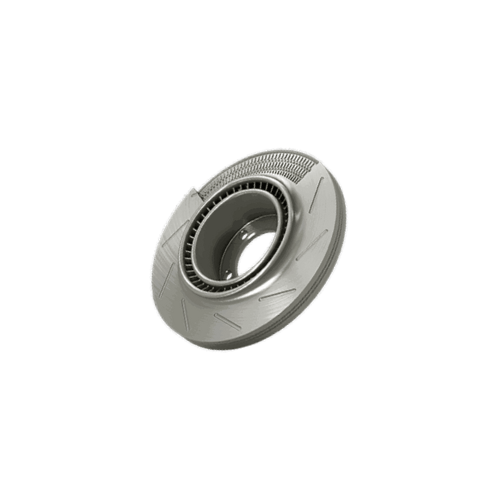

Inconel

Inconel is a high-strength, corrosion-resistant nickel-based metal ideal for extreme environments like aerospace and power generation. Its excellent oxidation resistance allows it to maintain mechanical integrity at elevated temperatures.

DEK specializes in Inconel metal 3D printing, producing complex, heat-resistant parts such as turbine blades and exhaust components. Our advanced metal 3D printing process guarantees precise geometries, durability, and consistent performance for applications requiring strength under severe thermal and mechanical stress.

Alliage

Inconel 718, 625, 600, etc.

Magnésium

Magnesium is one of the lightest structural metals, offering a unique combination of strength, low density, and good thermal conductivity. It is used in aerospace, automotive, and lightweight engineering applications.

DEK provides metal 3D printing for magnesium components, delivering lightweight yet strong parts with intricate designs. Our process ensures dimensional accuracy and repeatable quality for prototypes and end-use applications.

Alliage

MgAZ318, MgAZ61B, MgAZ91D, etc.

Acier inoxydable

Stainless steel is a versatile metal known for its strength, corrosion resistance, and weldability, used across medical, industrial, and structural applications. It supports hygienic and durable components.

We use metal 3D printing to produce stainless steel parts with tight tolerances and excellent surface finishes. We manufacture intricate parts like surgical tools and mechanical brackets with consistent quality, enabling rapid prototyping and small- to medium-scale production for industries demanding robust metal components.

Alliage

Acier inoxydable 301, 303, 304, 304L, 316, 316L, etc.

Titane

Titanium is a strong, lightweight, and corrosion-resistant metal widely used in aerospace, medical implants, and high-performance engineering. It offers an excellent strength-to-weight ratio and biocompatibility.

DEK provides titanium metal 3D printing services capable of producing complex geometries like surgical implants, brackets, and housings. Our technology delivers parts with precise dimensions, high durability, and smooth finishes, ideal for critical applications where weight savings and material performance are essential.

Alliage

Titane Grade 1, Grade 2, Grade 5, etc.

Acier à outils

Tool steels are high-hardness metals designed for wear resistance, toughness, and durability, commonly used in tooling, molds, and dies. They withstand high loads and mechanical stresses.

DEK offers metal 3D printing for tool steel parts requiring complex shapes and superior mechanical properties. Our process ensures dimensional accuracy, repeatability, and long tool life, making it suitable for injection mold inserts, cutting tools, and custom tooling components in demanding manufacturing environments.

Alliage

Acier à outils A2, A3, D2, S7, etc.

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Nos avantages

2300+ ingénieurs Aimer travailler avec nous

Material Flexibility

DEK works with a broad range of metals, including aluminum, titanium, stainless steel, Inconel, cobalt-chrome, and custom metal powders. This material flexibility enables engineers to choose the best metal for strength, weight, heat resistance, or corrosion protection.

Tolérances serrées

DEK achieves excellent precision in metal 3D printed parts, with tolerances typically within ±0.005 mm. This level of accuracy ensures that parts fit and function as intended, even in high-performance applications.

Finitions de surface personnalisées

DEK offers multiple post-processing options for metal parts, such as polishing, sandblasting, bead blasting, and coating. These finishing processes enhance surface aesthetics, wear resistance, and corrosion protection.

No Order Limits

DEK supports flexible production volumes with no minimum order quantity. Whether you need a single prototype or a low-to-mid-volume production run, DEK adapts to your needs. Explore metal 3D printing without committing to large batch quantities or high upfront manufacturing costs.

Complex Geometry Printing

DEK’s metal 3D printers can produce highly intricate geometries, including internal channels, lattice structures, overhangs, and organic shapes. This design freedom is ideal for lightweighting, fluid flow optimization, and part consolidation.

Une production rentable

Metal 3D printing at DEK reduces overall production costs by minimizing waste, eliminating tooling, and shortening development timelines. Especially for low-to-mid volume orders or complex geometries, additive manufacturing becomes significantly more economical than traditional CNC or casting methods.

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.

Envoyer l'appel d'offres 222

Revue et citation

Confirmer la commande

Production

QC

Livraison

FAQ

Métal 3D FAQ sur l'achat

Obtenir un devis précis Pour vos prochains projets

Que votre projet soit simple ou compliqué, qu'il s'agisse de métal ou de plastique, vous obtiendrez un devis précis dans les 6 heures.

Obtenir un devis aujourd'huiImpression 3D de métaux Perspectives

Qu'est-ce que l'impression 3D sur métal ?

L'impression 3D de métaux fait référence à divers procédés de fabrication additive qui permettent de construire des pièces métalliques couche par couche à partir de données de modèles 3D sans les contraintes des méthodes soustractives traditionnelles. Les technologies les plus courantes sont la fusion sur lit de poudre, le dépôt d'énergie dirigée et la projection de liant.

Une source de chaleur ciblée, comme un laser ou un faisceau d'électrons, fait fondre et fusionne sélectivement de la poudre ou du fil métallique en fines couches, sur la base des coupes transversales du modèle CAO 3D, afin de construire un objet physique. Une large gamme de métaux peut être imprimée, de l'acier inoxydable et du titane aux alliages de nickel, à l'aluminium et au chrome-cobalt. Par rapport à la fabrication conventionnelle, cette approche offre une liberté de conception très innovante pour des géométries complexes, légères et personnalisées. L'impression 3D de métaux excelle dans le prototypage rapide, l'outillage de pont et la production de volumes faibles à moyens.

Quels sont les avantages de l'impression 3D sur métal ?

Metal 3D printing enables the production of high-performance components with greater speed, flexibility, and design freedom than traditional manufacturing.

- Lightweight structures

- Reduced material waste

- Pas d'outillage nécessaire

- Prototypage rapide

- Flexible production

- Faster turnaround

- Fewer assemblies

- Strong, durable parts

- Low-volume efficiency

- Optimized material use

- Custom designs

When Do You Use Metal 3D Printing?

Metal 3D printing is great for projects that require quick production, detailed customization, or small batches without the need for molds or tools. For example, in aerospace, it’s used to make engine parts, brackets, and heat exchangers that must perform under extreme conditions. In the medical field, doctors and dentists use it to create custom implants, surgical tools, and prosthetics made to fit each patient perfectly.

This technology is also widely used in the automotive industry to design and test lightweight parts quickly, such as exhaust manifolds or heat shields. In factories, it helps produce useful tools, jigs, and fixtures that support day-to-day manufacturing tasks. Metal 3D printing is also popular in fields like architecture, jewelry, and consumer electronics, where detailed and artistic metal designs are needed. Even in research labs, it’s used to create metal samples for testing and experiments.