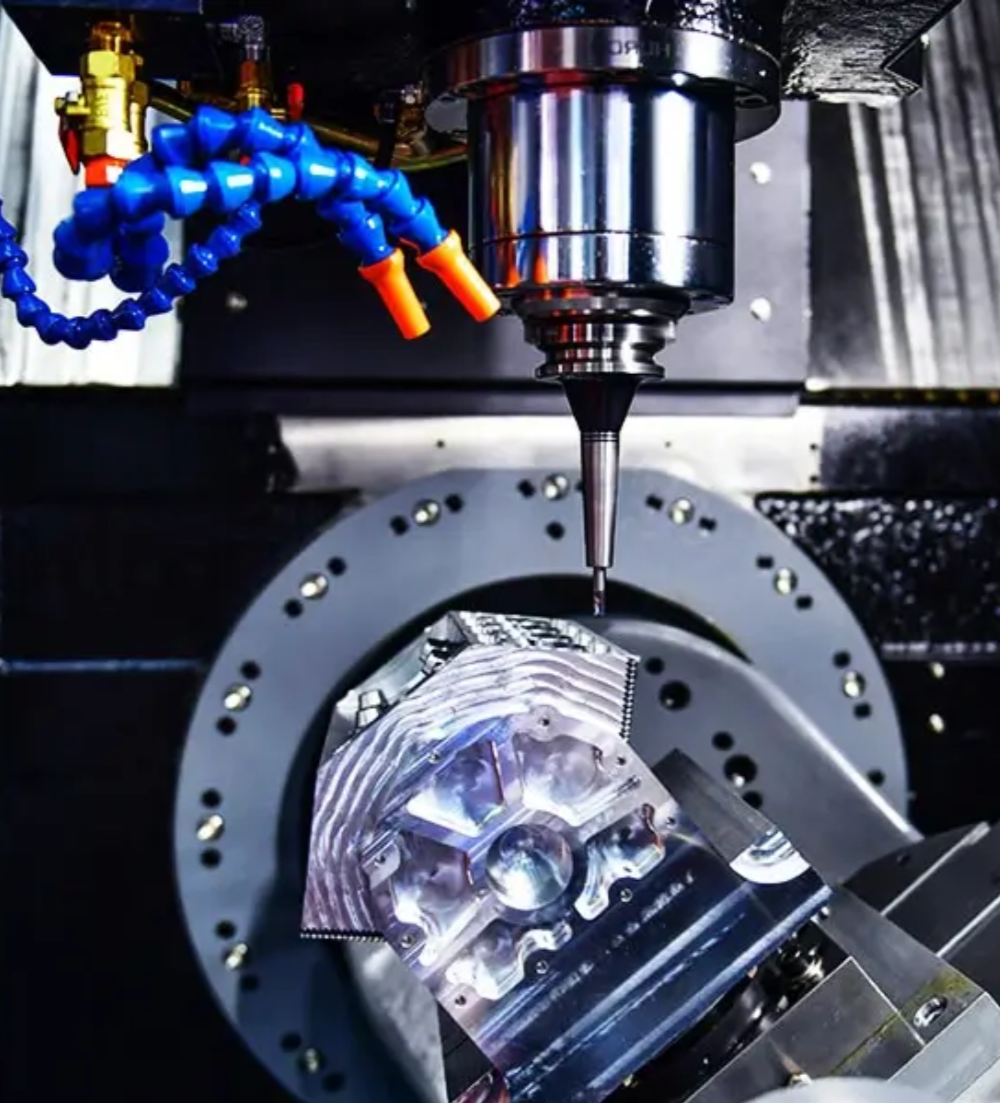

Multi-Axis CNC Machining Service

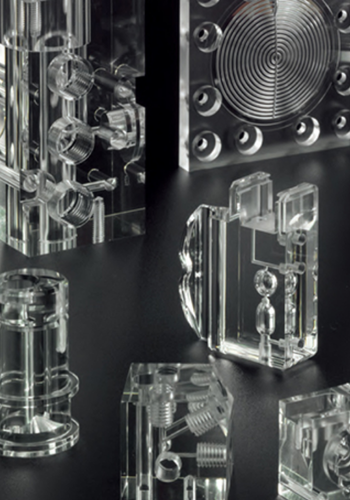

Get high-precision multi-axis CNC machining services to meet your strict demands, from prototyping to full-scale production with our advanced CNC technology.

Here at DEK, we deliver quality results, whether you are dealing with demanding materials and tight tolerances. Our multi-axis capabilities will get you covered by delivering superior accuracy and efficiency to fit your production needs. Our experienced team is ready to cater to your automotive, medical, and industrial manufacturing needs.

introduzione

Next-Level Precision with Multi-Axis CNC Machining Services

The multi-axis CNC machining service we provide delivers high-precision parts with tight tolerances, using the latest technology to ensure efficiency and consistency while meeting the needs of any production volume.

Here at DEK, our multi-axis CNC machining service includes advanced 3-, 4-, and 5-axis CNCs that are capable of handling complex geometries effectively. We work with various high-end materials to meet your standards and requirements for your manufacturing needs. Our competent team uses industry-leading software and processes to ensure efficiency every step of the way.

Our strong focus on quality control ensures that all parts will go through strict inspections and systems. We also ensure on-time delivery that makes industries like aerospace, medical, automotive, and electrical rely on our expertise.

- Advanced 3-, 4-, 5-axis machines

- Tolerances up to ±0.005mm

- Complex shapes and undercuts

- Fast prototyping, scalable runs

- Full inspection and QC reports

- Metals, plastics, custom materials

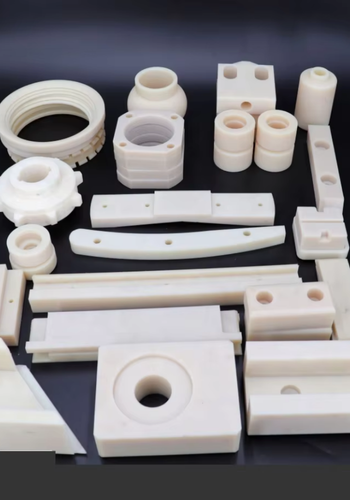

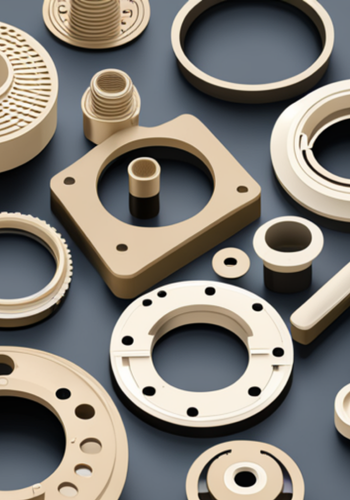

I materiali for Multi-Axis CNC Machining

Metalli

Plastica

Alluminio

Aluminum is a material widely used in CNC machining and is popular for its low density, strong corrosion resistance, and good electrical and thermal conductivity. It’s ideal for industries such as aerospace, automotive, and electronics due to its strength-to-weight ratio and workability.

At DEK, we specialize in multi-axis CNC machining of aluminum alloys, including 6061, 7075, and 5083. We deliver high-quality components such as engine casings, radiators, and spacecraft housings with tight tolerances and consistent performance.

Lega

AL6061, AL6063, AL5083, AL5052

Ottone

Brass is known for its excellent machinability, corrosion resistance, and high conductivity, making it a preferred material for precision components in industries like plumbing, electronics, and decorative hardware. Its low friction and smooth finish also make it suitable for moving parts and fittings.

DEK offers multi-axis CNC machining service for brass alloys such as C260, C360, and C464. We produce detailed parts like electrical connectors, valve components, and precision bushings with exceptional surface quality and dimensional accuracy.

Lega

C260, C360, C464

Rame

Copper is valued for its outstanding electrical and thermal conductivity, making it crucial for power transmission and heat dissipation applications. It's also naturally antimicrobial and corrosion-resistant, and commonly used in electronics, medical, and HVAC systems.

With advanced multi-axis CNC machining capabilities, DEK machines copper alloys like C101, C110, and C145 to create complex parts such as heat exchangers, electrical terminals, and RF components with high accuracy and finish.

Lega

C101, C110, C145

Inconel

Inconel is a high-strength superalloy engineered for extreme heat, corrosion, and pressure resistance, making it ideal for harsh environments. Commonly used in aerospace, marine, and energy industries, it performs reliably under stress.

DEK specializes in multi-axis CNC machining of Inconel 625 and 718, delivering high-precision turbine blades, exhaust components, and pressure-resistant seals. Our advanced capabilities ensure consistent quality, tight tolerances, and long-lasting durability, meeting the rigorous standards required for critical applications in the most demanding conditions

Lega

Inconel 625, Inconel 718

Acciaio dolce

Mild steel is a durable, adaptable material commonly used in structural, automotive, and tooling applications. Known for its strength, machinability, and cost efficiency, it remains a key choice across various industries.

DEK provides multi-axis CNC machining for mild steel alloys, delivering accurate and consistent results. We produce components such as gear shafts, industrial brackets, and custom tooling with precision and efficiency. Our capabilities ensure fast turnaround times and reliable quality for both prototyping and production needs.

Lega

1018, 1045, A36

Acciaio inox

Stainless steel is a strong, corrosion-resistant material well-suited for high-performance and sanitary applications. Widely used in medical, automotive, and industrial sectors, it offers excellent durability and wear resistance.

DEK offers multi-axis CNC machining for stainless steel grades including 303, 304, 316, and 17-4PH. We produce intricate components such as surgical instruments, valve bodies, and pump housings with exceptional precision. Our advanced machining ensures repeatable accuracy, smooth finishes, and reliable performance for parts used in demanding environments.

Lega

303, 304, 316, 17-4PH

Titanio

Titanium is a lightweight, high-strength metal known for its corrosion resistance and performance in extreme environments. It’s widely used in aerospace, medical, and advanced automotive applications for critical components.

DEK specializes in precision multi-axis CNC machining of titanium alloys such as Grade 2 and Grade 5 (Ti-6Al-4V). We manufacture complex parts, including orthopedic implants, turbine supports, and engine casings, with exceptional accuracy. Our expertise ensures tight tolerances, excellent surface finishes, and consistent quality for the most demanding industries.

Lega

Grado 2, Grado 5 (Ti-6Al-4V)

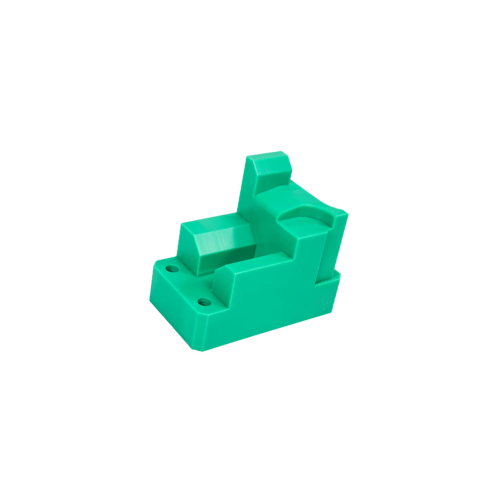

ABS

ABS is a tough, lightweight thermoplastic known for its impact resistance, machinability, and affordability. It’s widely used in enclosures, prototypes, consumer electronics, and other applications requiring durable, cost-effective solutions.

DEK offers multi-axis CNC machining for various ABS grades, including flame-retardant and black variants. We manufacture components such as device housings, structural models, and testing jigs with precision and smooth surface finishes. Our efficient processes ensure fast turnarounds and consistent quality, making ABS a reliable choice for both product development and high-volume production needs.

Delrin

Delrin (acetal) is a high-strength, low-friction plastic with excellent wear resistance and dimensional stability. It performs well in demanding mechanical applications, including gears, bushings, and rollers, where precision and smooth operation are essential.

Here at DEK, we utilize advanced multi-axis CNC machining to work with Delrin 150 and Delrin AF. We manufacture components like linear slides, gear mechanisms, and custom fittings to tight tolerances. Delrin’s stiffness and low moisture absorption make it a top choice for parts requiring reliable, long-term mechanical performance across a variety of industries.

Nylon

Nylon is a versatile, high-performance plastic recognized for its strength, flexibility, and resistance to wear and chemicals. It's ideal for components exposed to continuous motion, friction, or load, and is commonly used in automotive, industrial, and consumer product applications.

DEK machines Nylon 6, Nylon 6/6, and glass-filled options using precise multi-axis CNC equipment. We produce parts such as pulleys, clamps, guides, and spacers with exceptional reliability and consistency. Our process ensures stable performance in parts that must endure challenging operational conditions and mechanical stress.

SETTIMANA

PEEK is an advanced thermoplastic engineered for extreme conditions, offering superb mechanical strength, chemical resistance, and thermal stability. It is commonly used in aerospace, medical, and semiconductor industries for critical parts requiring long-term durability and high precision.

At DEK, we provide multi-axis CNC machining for PEEK 1000 and PEEK CF30, producing parts like surgical implants, aerospace bushings, and electrical insulators. Our services maintain tight tolerances and material integrity, ensuring every component meets the highest standards for functionality and performance in high-stress, high-value environments.

PET

PET is a strong, dimensionally stable plastic that offers excellent electrical insulation, wear resistance, and form retention under mechanical stress. Commonly used in electronics, laboratory equipment, and structural applications, PET performs well in environments where durability and consistency are crucial.

DEK uses advanced multi-axis CNC machining to work with PET and glass-filled PET variants. We produce parts like spacers, precision mounts, and sensor holders with accuracy and reliability. PET's stability makes it a reliable choice for components requiring long-term structural and dimensional integrity.

PMMA

PMMA (acrylic) is a transparent, lightweight plastic known for its clarity, weather resistance, and impact strength. It is widely used in applications that require optical performance or visual presentation, such as displays, lighting systems, and protective covers.

At DEK, we offer precision multi-axis CNC machining for both clear and impact-modified PMMA grades. We manufacture components like lenses, light guides, and see-through housings for use in medical, commercial, and electronic products. Our services ensure optical quality, smooth finishes, and accurate dimensions for critical visual and functional requirements.

PTFE

PTFE (Teflon) is a chemically inert, heat-resistant plastic with low friction and non-stick properties, making it ideal for sealing, insulating, and fluid-handling applications. It’s commonly used in chemical processing, food handling, and electronics.

DEK utilizes advanced multi-axis CNC machining for both virgin and glass-filled PTFE. We produce high-performance parts such as valve seats, electrical insulators, and lab seals to exact specifications. Our machining process ensures consistent quality and reliable function in extreme environments where thermal, chemical, and mechanical stability are essential.

Immediato e Citazioni precise

Non utilizziamo strumenti di quotazione automatizzati online, perché sono molto imprecisi. Le piattaforme di quotazione online si basano esclusivamente su calcoli basati su importi di taglio e coefficienti fissi, e non tengono conto delle reali sfumature di lavorazione, come la deformazione del materiale dopo il trattamento termico, gli stretti requisiti di tolleranza, la rettifica dopo il trattamento termico, ecc. Di conseguenza, i calcoli automatici dei prezzi possono portare a delle imprecisioni, aumentando i costi.

Ma da DEK potete stare tranquilli!

I nostri preventivi sono convenienti e accurati perché disponiamo di un team di ingegneri meccanici professionisti che esaminano meticolosamente ogni disegno. Questi ingegneri vantano oltre 10 anni di esperienza e possiedono una profonda competenza in materia di programmazione, funzionamento delle macchine, post-elaborazione, proprietà dei materiali e altro ancora. Vi assicuriamo preventivi accurati entro 6 ore.

I nostri vantaggi

Oltre 2300 ingegneri Amore Lavora con noi

Precisione e tolleranze

Our multi-axis CNC machining delivers ultra-precise parts with tolerances as tight as ±0.005mm. With advanced equipment and skilled technicians, we maintain consistent dimensional control throughout every stage of production, even on the most complex geometries.

Material Variety

Our capabilities span a wide range of materials, including aluminum, stainless steel, titanium, brass, copper, and engineering plastics. We also accept customer-supplied materials when required. This material versatility allows us to support a broad spectrum of industries.

Tempi rapidi

We understand the importance of speed in today’s manufacturing world. Our streamlined workflow, advanced CNC equipment, and experienced team enable us to deliver your order in as little as 4–7 days. We meet tight deadlines without compromising quality or accuracy.

Finiture di superficie

We offer a variety of surface finishes such as anodizing, plating, polishing, bead blasting, and powder coating to match your functional and aesthetic needs. These finishing services are available in-house, adding good performance to your machined components.

Complex Geometry

DEK specializes in producing intricate parts with curves, undercuts, and compound angles using advanced 4- and 5-axis CNC machines. These machines can do multiple sides in one setup, reducing errors and setup time. We’re equipped to handle designs that are too challenging for traditional machining.

Efficienza dei costi

Our multi-axis approach reduces the number of setups, tooling changes, and human interventions, leading to lower overall production costs. We help clients reduce waste, avoid rework, and get the most value from every part produced, especially in complex jobs.

Il nostro Processo di ordinazione

Invia RFQ

Inviare RFQ con disegni 2D/3D e requisiti dettagliati tramite e-mail o modulo online.

Recensione e preventivo

Il nostro team di ingegneri esaminerà attentamente ogni disegno e fornirà un preventivo accurato entro 6 ore.

Confermare l'ordine

Confermate il preventivo, i dettagli e il programma di consegna, quindi firmate il contratto.

Produzione

Organizzare il processo di produzione, avviare la programmazione e la lavorazione.

Controllo qualità

Rigoroso controllo di qualità durante la produzione e l'ispezione finale.

Imballaggio e spedizione

Imballare i pezzi, applicare le etichette di identificazione e iniziare la spedizione.

Inviare RFQ 222

Recensione e preventivo

Confermare l'ordine

Produzione

QC

Consegna

FAQ

Multi-Axis CNC Machining Domande frequenti sull'acquisto

Ottenere un preventivo accurato Per i vostri prossimi progetti

Non importa se il vostro progetto è complicato o semplice, se è in metallo o in plastica, riceverete un preventivo accurato entro 6 ore.

Richiedete un preventivo oggi stessoComprensione Multi-Axis CNC Machining

What is Multi-Axis CNC Machining Service?

Multi-axis CNC machining is a high-precision manufacturing process where cutting tools move along multiple axes to shape and produce complex parts. Unlike traditional 3-axis machines that operate on the X, Y, and Z axes, multi-axis CNC machines (such as 4-axis and 5-axis) can rotate and tilt the workpiece or the cutting tool, allowing for more intricate machining in a single setup. This advanced capability reduces manual repositioning, enhances accuracy, and enables the production of detailed components with tight tolerances.

The service includes everything from prototyping to large-scale production, helping manufacturers streamline production time, reduce errors, and maintain consistent quality across all parts.

What are the advantages of Multi-Axis CNC machining service?

Multi-axis CNC machining offers significant advantages over traditional methods by allowing complex parts to be produced more efficiently, accurately, and with fewer setups. It enhances productivity while maintaining high precision and quality, especially for intricate or high-tolerance components.

- No multiple setups and repositioning

- High precision

- High dimensional accuracy

- Finitura superficiale migliorata

- Short production time

- Less human error and tool changes

When do you need Multi-Axis CNC machining service?

You need a multi-axis CNC machining service when your part designs involve complex shapes, tight tolerances, or multiple sides that need to be machined with precision. Traditional 3-axis machines can struggle with intricate angles or deep cavities, often requiring multiple setups, which increases the risk of errors and adds to the production time. Multi-axis CNC machines solve this by allowing the cutting tool or workpiece to move in multiple directions, enabling more efficient and accurate machining in a single setup. This service is especially valuable for industries like aerospace, medical, automotive, and robotics, where component complexity and precision are non-negotiable. If your project includes curved surfaces, compound angles, or features that are difficult to reach using basic equipment, multi-axis CNC machining is likely the best solution.