Machining carbon fiber has become critical in the industry, as we often need lightweight yet tough components. When compared with metals, carbon fiber offers an astonishing performance without adding weight. It will find applications in aerospace, sports, automotive, and electronics, as it stabilizes strength and weight better than most materials.

This blog gives you everything there is to know about machining carbon fiber. Starting from the properties and methods down to applications and machining techniques. You will learn how to apply mechanical skills to handle this complex material.

What is Carbon Fiber?

Carbon fiber is made from light filaments of carbon atoms that are bonded in a crystalline form. Each filament is extremely fine, around 5-10 microns, with thousands of filaments being bundled together to form a lightweight yet strong composite.

Typically, carbon fiber sheets are woven into fabrics and mixed with resin to form verified composites that boast an unparalleled strength-to-weight ratio compared with any metal. Hence, machining carbon fiber composites has gained wide importance in complex fields.

How to Make Carbon Fiber?

Fibre de carbone starts its process from the initiator, which is most frequently polyacrylonitrile (PAN). Rayon and pitch are also used. The steps are as follows:

Spinning: The raw material is rotated into thin filaments.

Stabilization: Fibers are heated in air for stabilization of the structure.

Carbonization: Stabilized fibers are heated up to 3000°C in an inactive atmosphere.

Surface treatment: Fibers are treated to improve bonding with binders.

Sizing: A defensive coating is added to the fibers for easier handling.

These multiple-step processes create fibers with outstanding inflexibility, strength, and a low weight-to-weight ratio. These could be used for machining carbon fiber sheets or blocks.

Properties of Carbon Fiber

| Propriété | Description |

| Strength-to-Weight Ratio | Stronger than steel yet much lighter |

| Dilatation thermique | Very low, stable under heat |

| Conductivité électrique | Conducts electricity effectively |

| Résistance à la corrosion | Withstands chemicals and moisture |

| Apparence | Glossy, modern woven look |

| Résistance à la fatigue | Excellent under repeated stress |

These unique characteristics explain why CNC machining of carbon fiber has become so important in industries where performance matters.

Carbon Fiber Machining Processes

Découpage

Cutting carbon fiber looks simple and easy, but it is not. Unlike metals, carbon fibers tend to splinter if you use the wrong tool. This is the reason why diamond blades are used. The cutting methods give very clean edges, and less splitting occurs on sites that have been machined.

When cutting carbon fiber sheets, one should work with slow feed rates and sharp tools. That way, one guarantees that the parts come out in true dimensions with no product defects on the edges.

Forage

Drilling carbon fiber composite materials is one of the hardest methods. The fibers are complex, and if one applies too much pressure, they cause them to divide. To prevent this, one must use drill bits that are meant for composite materials.

Sharp tips, slow speeds, and continuous dust extraction are needed. If not, carbon dust can build up and find its way into the machines or even the skin of those working on it. Remember, wear gloves and a respirator whenever you drill.

Fraisage

Fraisage CNC rules as the workhorse for machining carbon fiber blocks. Custom features such as slots, pockets, and non-standard complex shapes can be cut easily. Such machining requires high speeds with low feed rates.

The threat is too much heat. Carbon fiber does not conduct heat well. Hence, the heat remains in the material, reducing the resin. Thus, machinists must carefully balance speed and feed to prevent burning the part.

Tournage

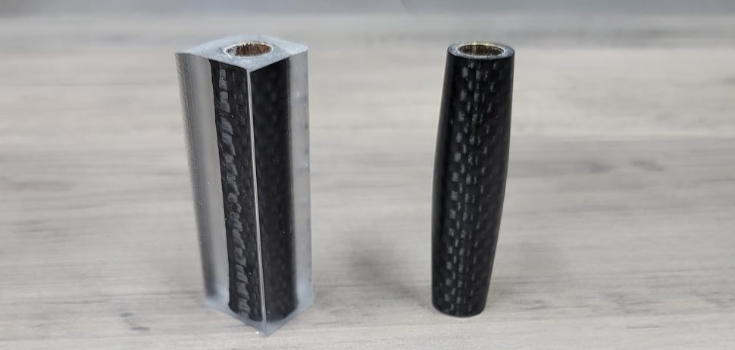

When you require round shapes or cylindrical parts, Tournage CNC is one of the good options for you. With the accurate tool setup, you can get an accurate range for carbon fiber parts.

You cannot just use any cutting tool. Steel will wear out quickly as carbon filaments are highly abrasive. The tools will thus need to be carbide, ceramic, or diamond-coated. The surface quality derives from the right feed rate and cutting angles.

Post-Machining Finishing

You finish machining after cutting, drilling, or milling your parts. Carbon-fiber parts need post-machining finishing to be functional and attractive. You may require sand, polish, or coat surfaces to remove any burring and offer protection.

Most of the time, protective layers or resin coatings are included for strength. Using this technique, your machined carbon fiber composites would also look professional and work as intended.

Advantages and Disadvantages of Carbon Fiber Machining

Avantages

- Stronger than steel but lightweight.

- Corrosion and chemical-resistant.

- Stable under heat with a low rate of expansion.

- Can be machined into complex shapes.

Inconvénients

- Prices for the raw materials are high.

- It requires specialized tools and skills.

- Conductive dust can be hazardous.

- Recycling options are limited.

Applications of Carbon Fiber Machining

Robotique et automatisation

Robots require speed and accuracy. Mechanizing carbon fiber sheets to form robotic arms or structural frame components reduces weight while providing an increase in stiffness. It allows robots to move faster and more efficiently with energy.

Carbon-fiber composite material can also resist vibrations. Its accuracy also improves in doing tasks in automation. Hence, the growing trend among industries is to take up carbon fiber machining services for implementing robotic systems.

Carbon Fiber Tactical Bridges and Ladders

Imagine carrying a ladder or bridge into the field, and every kilogram counts. That is where carbon fiber comes in. Bridges and ladders made from carbon fiber are strong enough to bear high loads. They are also so light that one can carry them easily.

Rescue teams and military units value this balance. You can get reliable equipment that performs under pressure without being a burden to carry.

Carbon Fiber in Musical Instruments

Musical instruments are typically made from wood, but carbon fiber is changing that. Violins, guitars, and pianos now have some carbon-fiber parts in their construction for the strength and stability of sound.

Unlike wood, carbon fiber does not bend with humidity or temperature. Therefore, musicians benefit from instruments that stay consistent in each performance. You get strength, stability, and a modern edge to sound design.

Industrie automobile

Supercars and race cars need carbon fiber machining service for frames, panels, and spoilers since lightness is important for speed.

By simple replacement of their heavy metal components with carbon fiber blocks for machining, automakers get to make their vehicles lighter and more fuel-efficient. They give drivers cars that have better handling and low emissions.

Aircraft Systems

Aircraft is the first industry to adopt carbon fiber material, and machining is the aerospace industry. Airplane wings, fuselages, and interiors are comprised of carbon fiber parts to reduce weight and improve runway performance.

It means saving every kilogram down the stream means less fuel consumed. Over time, that saves millions and minimizes emissions. By Usinage CNC of carbon fiber, the manufacturers deliver parts designed to tight performance and safety standards.

Sports Industry

Right from tennis rackets to racing bicycles, carbon fiber is a favorite and beloved in the world of sports. Something in the field of carbon fiber is always a favorite with athletes in making their gear lighter and more feasible.

For instance, a carbon fiber racquet helps you swing fast. A carbon fiber frame helps you ride far with less effort. In any sport, you perform well with less effort. Therefore, sports brands invest a lot of money in machining carbon fiber composites.

Industrie électronique

Carbon fiber is equally interesting in electronics. It is conductive, lightweight, and strong. This makes it a great fit for enclosures, shielding devices, and precision components.

Electronics need shielding from electromagnetic interference. Machined carbon fiber composites absorb and block unwanted signals while keeping the design lightweight. You will also find carbon fiber parts in sensors, lasers, and advanced equipment.

Carbon Fiber Machining Tips

- Extend tool life by using diamond or carbide tools.

- Control dust with proper extraction systems.

- Prevent splintering and delaminating by adjusting feed rates.

- Manage heat buildup by controlling speed and depth.

- Always test the parameters on scrap pieces before machining the final piece.

Precision Machining Carbon Fiber Parts with DEK

When it comes to accuracy, DEK has you covered. DEK provides CNC machining carbon fiber solutions that fit your specific requirements. Our advanced machines and experienced engineers confirm clean cuts, accurate tolerances, and minimal waste.

You can count on us for both small prototypes and large production runs if you require machining of carbon fiber sheets, composites, or custom blocks. We guarantee top-quality results. Contactez nous today to start your carbon fiber machining project with complete assurance.

Conclusion

Precision machining of carbon fiber needs expertise. The right tools and a deep understanding of the materials with special properties. We combine advanced technology with years of industry experience to provide carbon fiber parts that surpass performance standards.