- Accueil

- Military and Defense

Precision Manufacturing of Military and Defense Components

DEK is a one-stop manufacturer of high-quality, complex, precision components for military and defense applications, with tight tolerances of ±0.005mm. Our expertise includes producing military components for ground defense vehicles, aircraft, spacecraft, electronics, and other military systems. Leveraging advanced CNC machining technology, we ensure reliable, competitively priced solutions with the highest quality and safety standards, compliant with DFAR regulations.

- Assistance technique 24 heures sur 24, 7 jours sur 7

- Rotation rapide, délai d'exécution court, pas de MOQ

- Instant Quotes and DFM Feedback

- Both Low and High Volumes Are Available

- ISO 9001:2015, AS 9100 certified and ITAR-qualified

Custom Military and Defense Parts Manufacturer

DEK is renowned for its superior quality and comprehensive services, providing reliable, precise, and flexible customized solutions for the defense industry based on demand.

As an ISO 9001 certified manufacturer, DEK specializes in high-precision military components, achieving tight tolerances of up to ±0.005mm. We strictly adhere to defense industry standards, excelling in machining titanium alloys, stainless steel, aluminum alloys, tungsten steel, and Inconel, ensuring that DEK’s components can withstand harsh conditions and maintain reliable performance.

Additionally, we offer surface treatments such as anodizing, electroplating, PVD coating, and plating. Our typical products include housings, end bells, starter rings, and other components. All quality inspections are conducted in-house, and we provide CMM inspection reports, FAI reports, material certificates, and RoHS certification.

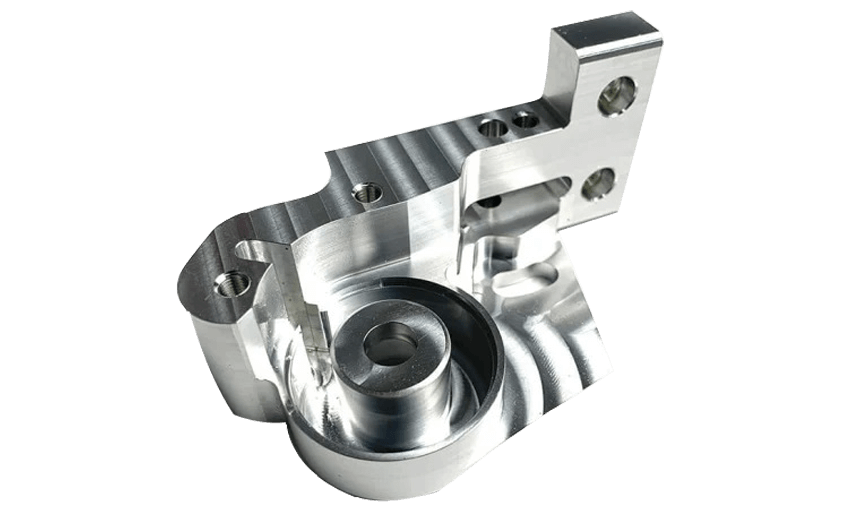

Defense Machined Part

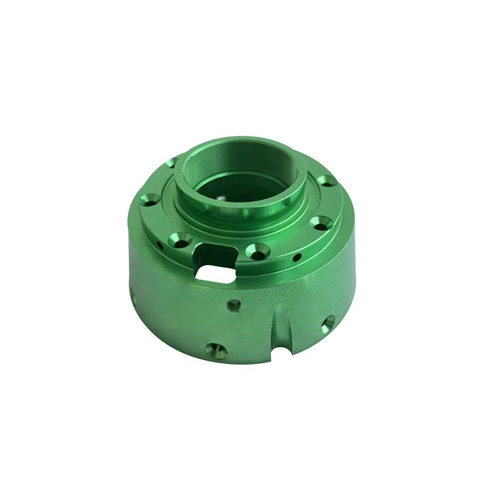

Aluminum Part for Military

Turned Miltary Part

Spare Parts for Defense

Military Machied Part

Machined Parts for Defense

CNC Turning Fastener

Military and Defense Component Capacités de production

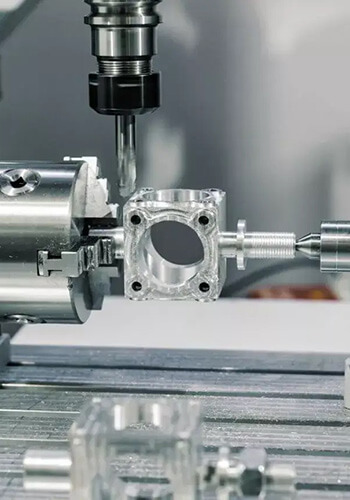

Usinage CNC de précision

DEK possesses multi-axis CNC machining, precision turning, and complex component manufacturing capabilities, including milling, grinding, turning, boring, and reaming, meeting the stringent requirements of military and defense applications.

It is highly suitable for manufacturing aircraft structural components, military vehicle components, and naval and submarine parts. Whether you need a prototype or are seeking a reliable partner for small to medium batch production, DEK focuses on using production-grade materials and implementing strict in-house quality control to provide flexible and efficient solutions.

Fabrication de tôles

DEK specializes in manufacturing high-quality custom sheet metal parts for military and defense applications, including military enclosures & casings, brackets & mounts, providing reliable structural support and protection for your critical components.

We offer a variety of sheet metal materials, including aluminum, stainless steel, and steel. From instant quotes to rapid production, you can obtain hundreds of high-quality sheet metal parts in just a few days. Additionally, we provide surface treatment options, including brushing, anodizing, and coating, to meet the high demands of your components.

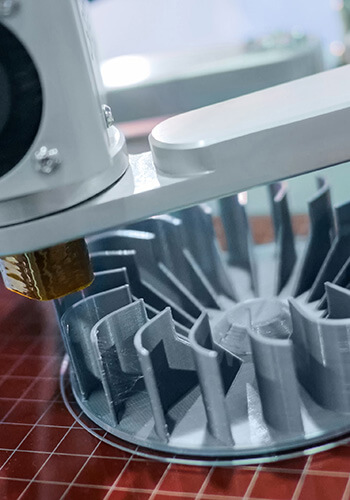

Impression 3D industrielle

DEK offers high-quality additive manufacturing services, enabling cost-effective rapid prototyping and on-demand production of wear-resistant, durable, complex geometric parts.

We provide a wide range of metals and plastics, including steel, PEEK, nylon, TPU, and PPS, for printing on-demand spare parts, UAV parts, custom jigs, and fixtures. Additionally, we offer surface treatments tailored to your project’s needs.

Extrusion d'aluminium

Industrial aluminum profiles, with their high strength, lightweight, corrosion resistance, and exceptional design flexibility and modularity, have become indispensable structural materials in the military and defense industry.

DEK provides high-quality aluminum extrusion parts for the military and defense sector. Our classic cases include shelter frames, structural rails, heat sinks for electronics, and superstructure components. We can flexibly handle your projects, offering cost advantages in batch production.

Matériaux

Matériaux Options

Acier allié

Alloy steel, known for its high strength, low cost, and adjustable toughness, is widely used in the military and defense industry, serving as a cornerstone material for heavy-duty equipment. Examples include aircraft landing gear actuators & joints, armored vehicle suspension components, and high-performance drivetrain gears.

Aluminium

Aluminum and its alloys are among the most widely used metals in the military and defense sectors, particularly aluminum 5083, aluminum 6061, and aluminum 7075. These alloys are highly suitable for manufacturing aircraft bulkheads and ribs, military electronics enclosures, satellite and spacecraft brackets, and other similar applications.

Titane

Titanium, with its high strength-to-weight ratio, excellent corrosion resistance, and high-temperature durability, is the preferred material for critical, high-performance components in modern advanced military equipment. It is ideal for manufacturing aircraft structural parts, jet engine fan blades & discs, submarine pressure hulls, and ballistic armor plating.

Inconel

Inconel offers exceptional overall performance under extreme high temperatures, high stress, and oxidative or corrosive environments. It is ideal for manufacturing turbine blades, turbine discs, nozzles, high-temperature fasteners, missile propulsion parts, and combustor liners.

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Pourquoi choisir Nos services

La production unique de pièces de haute qualité vous permet d'économiser du temps et de l'argent.

Capacités d'ingénierie

Délai d'exécution rapide

Finitions de surface

Contrôle de la qualité

Assemblage de précision

Packaging and Logistics

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.