- Accueil

- Marine

Precision Parts Manufacturing for Marine and Boat Parts

DEK is dedicated to the manufacturing of precision-machined parts for the marine industry. We provide our global clients with high-quality, durable, and consistently reliable components for shipbuilding and marine engineering projects. DEK is capable of rapidly machining complex parts with tight tolerances controlled at ±0.005 mm, utilizing a variety of production-grade materials and surface treatment options. We offer precise, flexible, and reliable customized solutions for you.

- Assistance technique 24 heures sur 24, 7 jours sur 7

- Instant Quotes and DFM Feedback

- Both Low and High Volumes Are Available

- ISO 9001:2015 and ISO 14001:2015 certified.

- Rotation rapide, délai d'exécution court, pas de MOQ

Custom Machined Parts Manufacturer for the Marine Industry

DEK is renowned for its outstanding quality and exceptional service. DEK can provide precision machining of custom parts for the marine industry according to specific requirements.

As an ISO 9001 certified manufacturer, DEK possesses state-of-the-art machining capabilities, achieving precise tolerances as tight as ±0.005mm. We strictly adhere to marine industry standards and specialize in machining materials such as steel, stainless steel, aluminum alloys, copper-nickel alloys, and titanium, ensuring every part we produce offers outstanding corrosion resistance, durability, and wear resistance.

Furthermore, we provide a range of surface treatments including passivation, anodizing, electroplating, PVD coating, and QPQ coating. Our typical case studies include propellers, drive shafts, heat exchanger tube sheets, subsea connector housings, transducer housings, and custom flanges. Our components are reliably applied in corrosion-resistant, high-pressure, and extreme weather environments common in the industry.We also supply CMM inspection reports, First Article Inspection (FAI) reports, material certificates, and RoHS certification.

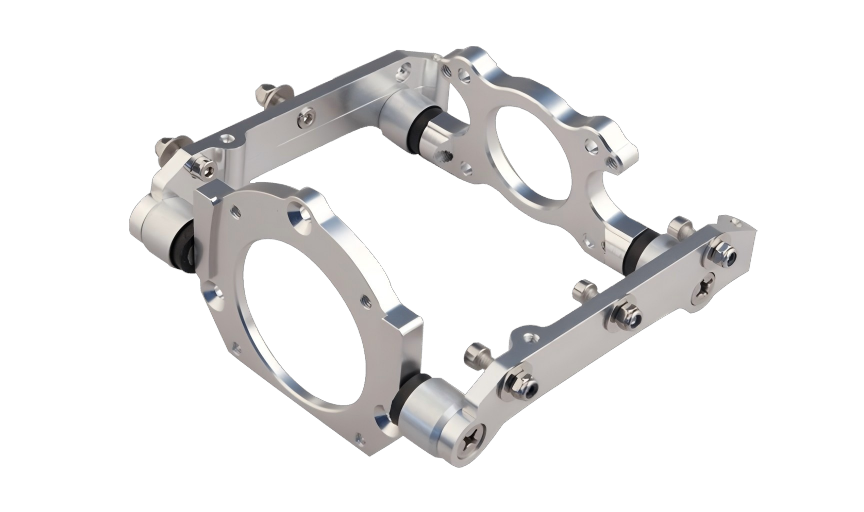

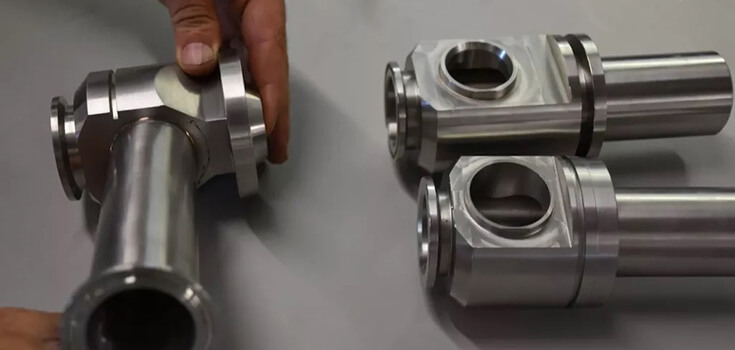

Marine Coupling

Marine Rail Guide

Thermoplastic Rubber Adapter

Marine Housing

Marine Component Capacités de production

Usinage CNC de précision

DEK possesses multi-axis CNC machining, precision turning, and complex component manufacturing capabilities, including milling, grinding, turning, boring, and reaming, meeting the stringent demands of marine applications. With tight tolerances up to ±0.005mm, we are ideally suited for producing high-precision components for propulsion systems, underwater navigation parts, and robust structural elements, such as propellers, shafts, windows, and molds.

Leveraging advanced CNC technology and skilled machinists, we deliver precisely engineered parts capable of withstanding harsh marine environments while adhering to strict industry standards. Whether you need a prototype or are seeking a reliable partner for small- or large-volume production, DEK focuses on using corrosion-resistant materials and implementing rigorous quality control to provide flexible, efficient solutions that perform reliably under extreme conditions.

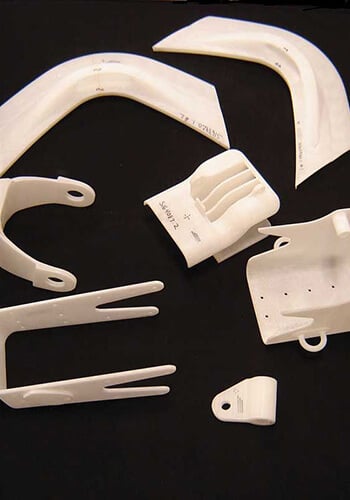

Impression 3D industrielle

DEK provides high-quality additive manufacturing services to help you create rapid prototypes at low cost and produce complex geometric parts that are wear-resistant, durable, and rust-proof on demand.

We can provide a wide range of metals and plastics, including stainless steel, aluminum, titanium, nylon, PEEK, and PEI, for printing custom propellers, replacement parts, custom ergonomic fittings, custom housings, and brackets for UUVs. Additionally, we offer surface treatments required for your projects.

Fabrication de tôles

DEK specializes in machining high-quality custom sheet metal parts for the marine industry, including radar mounting bracket, cable tray,ventilation louver, chain locker cover, and enclosure, providing reliable structural support and protection for your key components.

We offer a variety of sheet metal materials, including stainless steel, aluminum, and steel. From instant quotes to rapid production, you can receive hundreds of premium sheet metal parts in just days. Additionally, we provide surface treatment options such as brushing, anodizing, and coating to meet your parts' high demands.

Moulage par injection

DEK provides high-quality injection-molded parts for the marine industry, with particular expertise in marine safety and electronic equipment. If you are in the marine sector and seeking a plastic injection molding supplier, we offer comprehensive support from concept design to finished product manufacturing.

In applications where parts are exposed to corrosive environments, the use of thermoplastic materials offers unmatched longevity and durability compared to metal parts. Our classic case studies include thermoplastic rubber adapters, drive shafts, spring shafts, shift mechanisms, bearings, gear sets, dog clutches, seals, and gaskets. Whether you need 1 piece or over 10 million pieces, DEK can meet your volume requirements.

Matériaux

Matériaux Options

Acier

Marine-grade carbon steel and stainless steel are the most widely used and fundamental materials in marine applications, offering excellent machinability, high strength, corrosion resistance, and weldability. They are ideal for manufacturing propellers, anchors, platform legs, shafts, valve stems, and hydraulic cylinder piston rods. Additionally, we offer DLC coatings and PVD coatings.

Aluminium

Marine-grade aluminum alloys, particularly the 5xxx and 6xxx series, are highly favored in marine applications due to their lightweight properties and excellent corrosion resistance. They are ideal for manufacturing valve blocks, sheaves, instrument housings, steering nozzles, heat exchangers, rudder quadrant, jet drive impeller, hatch latch, outrigger mount, and ROV thruster propeller, hydraulic fittings, and precision mounting brackets.

Cuivre

Copper alloys, particularly copper-nickel alloys, are renowned in marine applications for their exceptional resistance to biofouling and corrosion. Combining excellent electrical and thermal conductivity, they are ideal for manufacturing propeller shaft bearings, valve seats, pump wear rings, propeller nuts, thru-hull fittings, silicon bronze screws, and pipe unions.

Titane

Titanium and its alloys are premium materials in marine engineering, renowned for their near-perfect corrosion resistance and extremely high strength-to-weight ratio. They are ideal for manufacturing propeller shafts, subsea sensor housings, arm components, custom rigging fittings, heat exchanger tube sheets, pump impellers, and acoustic transducer housings.

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Pourquoi choisir Nos services

La production unique de pièces de haute qualité vous permet d'économiser du temps et de l'argent.

Capacités d'ingénierie

Délai d'exécution rapide

Contrôle de la qualité

Finitions de surface

Assemblage de précision

Packaging and Logistics

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.