Welding and fabrication are critical processes in a more advanced manufacturing environment. They are usually spoken of together, but serve entirely different purposes. Both have an important role to play in the making of solid, reliable, and functional products across industries.

The difference between welding and fabricating helps to decide the right workflows for your project. This blog will help you through definitions, processes, tools, and benefits. Clarifies where they differ and connects.

What are Welding and Fabrication?

Fabrication is the full-fledged process by which a raw metal is transformed into its finished forms or components. Cutting, bending, machining, and assembling are some of the multiple steps in the fabrication. You can consider it as the larger picture of making a product.

Welding is a specialized process in the fabrication domain that involves the permanent joining of two or, in some cases, more pieces of metal by applying heat, filler, or pressure. Without fabrication, welding has nothing to join. Without welding, fabricated parts may lack strength and reliability.

The Metal Fabrication Process

Bidding

Bidding is the initial step in most fabrication projects. You prepare the cost estimates and the lists of materials to be used, and the timeline for their delivery to the client.

This stage requires technical know-how, excellent acquaintance with the market, and clarity in communication. A strong bid proves your ability to meet customer needs within budget and time.

Planning

Once a bid is accepted, planning confirms that every stage of production is mapped out. You select materials, allocate workers, and prepare detailed engineering drawings. Planning also covers safety, equipment setup, and resource scheduling. Without proper planning, fabrication projects can face delays or cost overruns.

Production

Production turns plans into reality. Skilled workers use machines and tools to cut, shape, and produce metal into its intended form. Quality checks happen throughout production to maintain accuracy. Depending on the complexity of the design, production can involve many small steps before the final assembly.

Types of Fabrication

Découpage plasma

Cuts metals conductively using a fast jet of ionized gas. This confirms faster, cleaner, and more accurate cutting as compared to traditional saws. It is very important for use in automotive, aerospace, and industrial applications where accuracy matters.

Drilling & Tapping

Drilling makes holes in metals with drilling bits. Tapping is adding threads to that metal for bolts and screws to fit firmly. The processing and tapping are both valuable in producing machines, automobile parts, and structures that need strength to hold well.

Polissage

Polishing is used to decorate the surfaces of metallic parts, provide a stylish look, reduce roughness, and offer limited protection against rust. Polishing is often industry-specific and functional (instruments) or purely decorative (furniture or jewelry).

Machining

Machining can create heavy metal into definite shapes and dimensions that might be very accurate and well-defined. The most common and general processes in machining are milling, turning, and grinding. Machining is needed when limits are very tight.

In other words, a part fits ideally in the system. Applications under precision machining go into the aerospace, medical, and automotive industries.

Pliage

Bending is a technique to change the physical form of a metal sheet without it breaking. Normally, people use press brakes and rollers for bending. It takes shape angles, curves, and rounded edges. Bending can create everything from tubes to brackets, producing highly fit designs with maintained material strength.

Assemblée

Assembly is the act of bringing all the manufactured parts together into a finished structure. It may be welding, fastening, or absorbing. In the last stage, small things become large products. For example, designing a vehicle, machine, or building, the frame, panel, and support are assembled into such larger products.

Cisaillement

Shearing is a method for cutting straight lines through metal sheets using sharp blades. It is generally used for rectangular pieces, but also for trimming off any excess material. Shearing is often chosen mainly because it is fast and high-volume capable.

Découpage

Among all cutting methods, saw, laser, and water jet cutting create a broad category of cutting. Each of these techniques has its special strengths.

While sawing is economical and simple, lasers are highly precise, and water jets cut without heat damage. The method best suited to the job will depend upon the project.

Punch Pressing

Punch press working is a method that forces a die down into deformation shapes for cutting or stamping sheet metals, as a means of revealing designs. It is useful for repetition and the very fast production of identical parts.

Punch press works by producing holes or slots, or other custom patterns, in industrial products.

Fabrication Tools

Fabrication depends on the tools for accuracy and efficiency. The most important fabrication tools include:

Press Brake: This tool is used to bend sheets into angles or shapes.

Shearing Machine: This tool is used for Straight-line cuts.

Welding Machine: A Welding Machine puts metal parts together.

Grinder: Grinder is mostly used for smoothing and finishing surfaces.

Drill Press: This is used for drilling holes and tapping precise, small holes.

Plasma Cutter: For fast-cutting, clean cuts in conductive metals.

Each tool depends on a different step, making the fabrication process complete.

Key Benefits of Metal Fabrication

Prominent advantages of fabrication include:

Personnalisation : One can design prototype components tailored towards a specific project standard.

Durabilité : Metal Structures and plastic are strong and can resist the wear and tear of life.

Polyvalence : Processes such as breaking, cutting, and process molding are applicable across industries.

Efficacité : Latest Appliance Fabrication tools shorten time and enhance productivity.

Quality: The right processes lead to end products of crucial quality.

These advantages explain why fabrication is important in construction, automotive, aerospace, and manufacturing industries.

Is Fabrication Different from Manufacturing?

Yes, fabrication and manufacturing are not the same. Manufacturing is the whole process of producing goods, which may use plastics, metals, or any other material. Fabrication is specifically considered the shaping and assembling of metals.

For example, metal body parts of the cars fabricated before the final assembly are a branch of manufacturing created under the aegis of fabrication.

The Welding Process

Soudage is the process of joining different kinds of metals, which is a permanent process. A degree of joint strength is created through heat, pressure, or the use of some welding filler material. In comparison to casting or invoking other temporary fasteners, welding creates bonds that will survive fixed stress and loading.

Welding is usually required for construction, shipbuilding, automotive, pipelining, and maintenance. Depending on the type of requirements, each of these requires a specific type of welding to ensure safety, durability, and efficiency.

Types de soudage

Shielded Metal Arc Welding (SMAW)

SMAW is also known as stick welding. It is one of the oldest and most commonly used processes. It uses a consumable electrode coated with flux to make the weld stronger. When the electrode melts, the flux produces a shielding gas that prevents the molten weld pool from pollution.

This method is flexible, reasonable, and works on thick materials. Making it popular in construction, pipelines, and heavy equipment repair. However, it needs skill to maintain spatter and electrode replacement.

Oxy-Acetylene Welding (OA)

Oxy-acetylene welding, also known as gas welding, uses a flame manufactured by burning oxygen and acetylene. It is mainly used for thin materials, sheet metal, and repair work. The flame temperature can exceed 3,200°C, enabling strong joints and easy cutting.

Although it is more time-consuming and less accurate than modern welding processes, it is still in current use in automotive repairs, art metalworking, and overall, in those applications where portability is an important factor.

Tungsten Inert Gas Welding (TIG)

TIG welding offers more precision and cleaner welds. It works with a non-consumable tungsten electrode to produce the weld. The shielding gas, generally argon, guards against oxidation. You can weld thin metals, like aluminum, stainless steel, and copper alloys, with great precision.

TIG welds are incredibly clean aesthetically. It finds its application in aerospace, medical devices, and high-end automotive manufacturing. It needs great skill and patience, but the results always prove to be the best.

Metal Inert Gas Welding (MIG)

MIG welding, or Gas Metal Arc Welding (GMAW), is one of the simplest welding techniques and is easy to learn. It is one of the fastest and most effective welding processes, especially suitable for larger projects with thicker materials.

In terms of productivity and application, MIG welding happens to be an unbeatable force in manufacturing, shipbuilding, and industrial applications. On the other hand, with simplicity, MIG welding is good for beginners, but the equipment demands a steady power supply and proper shielding gas.

Soudage à l'arc plasma

Similar to TIG welding, plasma arc welding employs a constricted plasma arc that maintains much higher temperatures. The advantage of this construction is the ability to attain deep penetration and precise control. It is suitable for aerospace components, electronics, and applications where ultra-high-quality welds are a must.

Plasma welding works on both thin and thick materials, making it flexible, but costly because the equipment is more complex.

Gas Tungsten Arc Welding (GTAW)

TIG welding is another name for this process, which involves using a tungsten electrode and shielding gas. The main difference between the two terms is that GTAW is the official technical term, while TIG is the common name.

GTAW highlights precision, control, and appearance of the weld, which is why it is greatly respected in industries where strong and defect-free joints are now the standard.

Submerged Arc Welding (SAW)

A continuously fed electrode is used in submerged arc welding, along with granular flux blanket coverage on the groove joint. The spatter is prevented, improving weld quality and permitting high access to take effect.

This technique perfectly welds thick steel plates over large areas. It has provided popularity in shipbuilding, pressure vessels, and structural construction. This limitation calls for using the process only in horizontal or flat positions.

Laser Beam Welding (LBW)

Laser beam welding uses a laser beam as a highly targeted source of heat. It welds very narrowly but more deeply, and with very little distortion. This welding process is fast and lends itself to automation operations. It is well-suited to electronic, automotive, and aerospace environments.

LBW perfectly fits into tolerances where critical rendering is involved. However, such outcomes on precision welding require expensive equipment for installation and strict safety measures due to high energy requirements.

Flux Cored Arc Welding (FCAW)

FCAW is similar to MIG welding. However, tubular wire filled with flux is used. This unique property allows outdoor welding without the use of any external shielding gas, especially under windy conditions.

Deep access and high deposition rates are functions of FCAW welding, making it suitable for use in construction, heavy machinery, and structural steel work. It is efficient, although not without the disadvantages of high smoke.

Gas Metal Arc Welding (GMAW)

GMAW is another term for MIG welding. It includes feeding a wire electrode through a welding gun while the weld itself is protected with shielding gas. This technique is commonly used in industries where speed and performance are needed.

The variation in terminology helps to identify the fact that MIG and GMAW in professional parlance are one and the same.

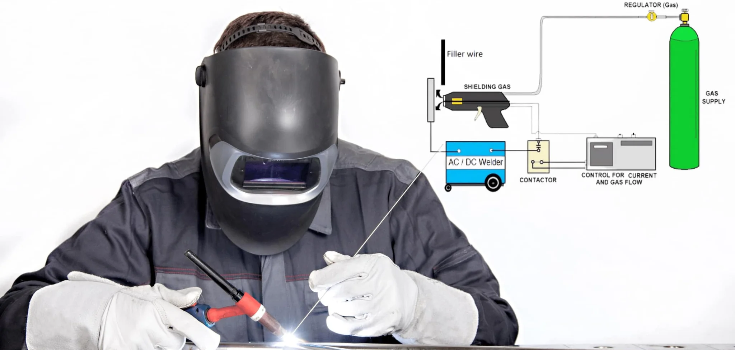

Welding Tools

For welders to perform their work, they require the following specific equipment:

Welding machine: The welding machine must provide heat energy.

Electrodes and wires: The weld is made from different consumables. These include electrodes and wires.

Protective helmet: The eyes and face should be protected from sparks by wearing a protective helmet.

Clamps: They should hold parts tightly together during welding.

Chipping hammer: The slag from welds should be removed with the help of a chipping hammer.

Angle grinder: The angle grinder has to be used to prepare and clean metal surfaces.

These tools provide good safety, efficiency, and accuracy in welding.

Key Benefits of Metal Welding

Welding provides several advantages:

Strong joints: Welded joints survive high stress and pressure.

Permanent connections: Unlike bolts, welds do not loosen.

Polyvalence : Anything from metals of various types to thicknesses can be welded.

Cost efficiency: Welding would do away with the cost sustained on expensive fasteners.

Adaptability: Performance techniques exist for both small repair and large-scale project work.

These are some of the reasons why welding is so important in various construction and manufacturing processes, as well as in repair applications.

Why is It Important to Understand the Basics of Welding?

The fundamentals of welding certify a general understanding of how products are manufactured and repaired. Without it, the assessment of project requirements is a big guess.

Certifications are equally necessary. Certified welders show that they meet all the industry requirements in terms of the quality and safety of their work. For a manager of a project, knowing these certifications will prove that the welder possesses the right skills for the job.

Also, from here, you know why welding is in existence, strong bonds where fasteners fail. From the pipelines to the skyscrapers, welding knowledge contributes to safety and performance.

Skill Sets Difference Between Welding and Fabricating

| Aspect | Welding Skills | Fabrication Skills |

| Primary Focus | Joining metals permanently | Shaping and assembling components |

| Knowledge Required | Metallurgy, heat control, safety standards | Reading blueprints, machining, and material selection |

| Tools Used | Welding machines, electrodes, and shielding gases | Cutting machines, drills, grinders, benders |

| Precision Level | High precision in creating strong joints | High precision in measuring and forming |

| Work Environment | Construction sites, shipyards, repair workshops | Manufacturing plants, fabrication shops |

| Training Needs | Welding certifications, safety compliance | Technical training in design, planning, and machining |

| Common Output | Welded joints, repairs, pipelines, structures | Frames, panels, enclosures, and equipment housings |

| Creativity Involved | Limited, mostly joining | Higher involves design and planning |

DEK - Your Reliable Partner in Welding and Fabrication

Au DEK, you can depend on expert welding and fabrication resources constructed for accuracy and productivity. Our team combines advanced tools with extensive technical knowledge to provide solutions throughout several industries.

Like custom fabrication, a specialized welding process for your projects can confirm that you are getting the highest quality standards. Professional accuracy and attention to detail always give you the same results. Trust us to be your most reliable partner for welding and fabrication excellence.

Conclusion

Understanding the core difference between welding and fabricating helps you choose the right process for your project. Welding is the art of putting together strong joints, and fabrication is the process of shaping and assembling parts to produce whole structures. Both demand skill, precision, and the correct tools.

By learning about their steps and advantages, you can make decisions for industrial, construction, or custom projects. Choosing one of the experienced professionals like DEK assures efficiency, safety, and superior quality, helping you achieve reliable results every time.