When building aerospace parts, you can’t just use any regular metal or plastic. You need to use materials that can survive extreme conditions.

This blog will discuss what materials are used in aerospace and why they are important.

What are Aerospace Grade Materials?

Aerospace grade materials are strong, light, and tough enough for aircraft like planes, drones, and satellites. They can handle extreme flying conditions, such as high speeds, pressure, and temperature changes.

But take note that not all aircraft are the same; that’s why there are different material grades for aerospace. Those grades cover a range of materials, depending on what kind of aircraft parts they are for.

Current Aerospace Material Trends

As the aerospace industry develops, a few big trends are leading the way, and these are the following:

- Continuous search for lighter materials to help aircraft perform better and use less fuel.

- Focus on how to make custom materials to be multifunctional

- Prioritizing materials that are easier to recycle, create less pollution, and are safer for people and nature.

Main Types of Aerospace Materials

Aerospace materials are grouped into four main types, and these are the following:

Metalli: They are strong and tough, so you’ll mostly find them in the aircraft’s frame and engine.

Compositi: These are made by combining two or more materials to get both strength and light weight.

Ceramica: These can handle very high heat. You’ll see them used in turbine blades and heat protection systems.

Polymers: These are plastics and rubbers. You’ll use them inside the cabin and parts that don’t need to hold much weight, because they’re flexible and don’t rust.

Top 5 Metals Used in the Aerospace Industry

These are the metals that are usually used to manufacture aerospace parts:

Leghe di alluminio

They are popular because they give you a great balance of light weight and good strength.

Advantages of Aluminum Alloys in Aerospace

- They are perfect for handling stress during flight because the parts are strong without being heavy.

- Aluminum is flexible and can be formed into many shapes, so it’s great when you’re designing for an aircraft frame.

- Aluminum naturally fights off rust by forming a protective layer. But for better protection over time, you can treat it with processes like anodizing or cladding.

- Compared to other aerospace metals, these alloys are cheaper and easier to find.

Common Types of Aluminum Alloys in Aerospace

2XXX Series (Aluminum Copper)

Very strong because of copper. You’ll find these in parts like fuselage sections and wing skins.

6XXX Series (Aluminum-Magnesium-Silicon)

Easy to shape and weld. These are great for non-structural or less critical parts.

7XXX Series ( Aluminum-Zinc)

Extra strong due to zinc. These are used in places like the upper wing where parts take a lot of stress.

Leghe di titanio

These are a favorite in aerospace because they’re both very strong and very light.

Advantages of Titanium Alloys in Aerospace

- Titanium alloys are strong like steel but lighter.

- Titanium forms a natural layer that protects it from rust, even in salty environments like the ocean.

- Some titanium alloys can work well even at high temperatures.

Common Types of Titanium Alloys in Aerospace

Alpha (α) Alloys: These are easy to shape and weld. They’re good when you need to make complex parts.

Alpha-Beta (α-β) Alloys: These have a nice balance of strength and flexibility. Use them for parts that take a lot of stress, like wing supports or the aircraft body.

Beta (β) Alloys: These are the strongest of the bunch. They’re perfect when you need maximum strength but want to keep the part as light as possible, like engine mounts.

Steel Alloys

Steel alloys are still one of the most trusted materials in the aerospace industry because they’re strong and dependable.

Advantages of Steel Alloys in Aerospace

- They can work well in tough aerospace environments because they can handle a lot of stress and pressure.

- Steel alloys usually cost less than other special aerospace metals and are easier to obtain.

- You can get the exact strength, toughness, or corrosion resistance you need for your part by adding different elements or using heat treatments.

Common Types of Steel Alloys in Aerospace

High-Strength Low-Alloy (HSLA) Steels: These have high strength and light weight. They are also affordable and easy to find.

Maraging Steels: These are super strong and tough. They stay strong in very cold temperatures.

Stainless Steels: Some types of stainless steel are strong and resist rust and corrosion. These are useful for parts exposed to the environment, like airframe parts or hardware on the outside of an aircraft.

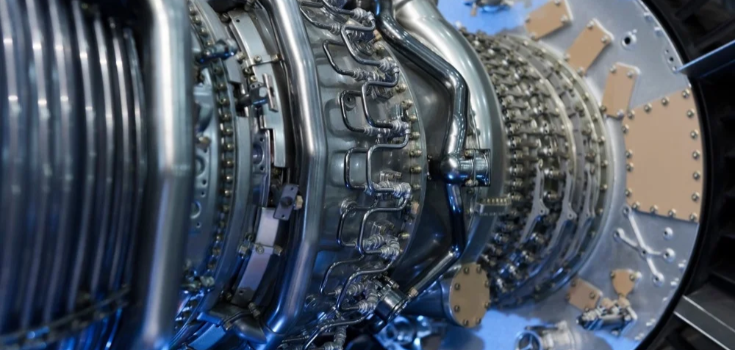

Superleghe

Superleghe, usually made with nickel, are built to work in extreme heat, over 1600°C. They stay strong and don’t lose their shape, even under constant stress, which is exactly what jet engines need.

Advantages of Superalloys in Aerospace

- Superalloys can handle way higher temperatures than regular metals.

- Superalloys include elements like chromium, cobalt, and tantalum, which help them resist oxidation at high heat.

- Even when things get super hot, superalloys stay strong and hold their shape.

Types of Superalloys Used in Aerospace

Nickel-Chromium (Ni-Cr) Superalloys: These give you a solid balance of heat resistance, strength, and protection from oxidation.

Nickel-Cobalt (Ni-Co) Superalloys: With more cobalt, these offer even better strength and creep resistance at high temperatures. They’re perfect for the hottest and most stressed parts.

Directionally-Solidified (DS) Superalloys: These are made in a way that lines up their internal grain structure in one direction. This makes them extra strong and heat-resistant, so they are ideal for the most extreme jet engine parts.

Leghe di magnesio

Magnesium alloys are the lightest structural metals you can get. They offer big benefits if you want to reduce weight in parti aerospaziali.

Advantages of Magnesium Alloys in Aerospace

- Using magnesium alloys can help you cut down weight, save fuel, and carry more cargo or equipment.

- They may not be the strongest, but even if they are so light, they still give you a good strength-to-weight ratio.

- Some magnesium alloys help absorb vibrations. This can make flights quieter and more comfortable for passengers.

Types of Magnesium Alloys in Aerospace

Magnesium-Aluminum (Mg-Al) Alloys: These are lightweight, and they have decent strength. They work well for parts that are not critical but still need some support.

Magnesium-Rare Earth (Mg-RE) Alloys: Adding rare earth elements makes magnesium alloys stronger and more stable under heat and stress. These are being tested for parts that need a little more strength without adding too much weight.

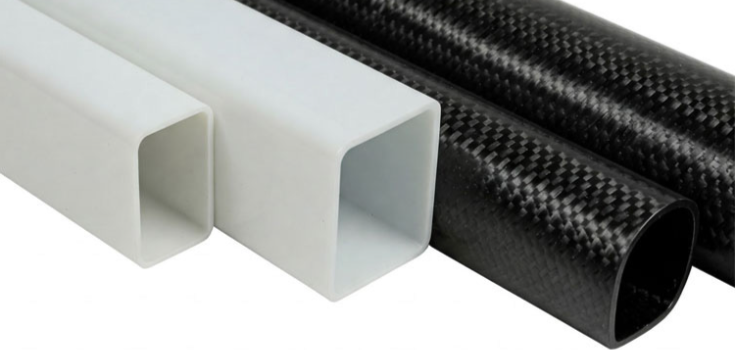

Advanced Composite Materials

You use advanced composite materials because they are strong, stiff, and light. They’re made by combining two or more different materials. Below are some of the common advanced composite materials:

Carbon Fiber-Reinforced Polymer (CFRP): This is very strong and lightweight

Glass Reinforced Plastic (GRP): This is also called fibra di vetro. It is strong, light, and resists rust.

Future Aerospace Materials

Even though great materials already exist for planes and spacecraft, people are still working on better ones, such as the following:

Nanoparticles: These are super tiny particles. You can mix them into other materials, like metals, to make them stronger and better.

Graphene: You know it from pencils, but it’s no lead; it’s made of thin layers of carbon. It’s great for carrying electricity, so it could be used in future airplane and spacecraft electronics.

Applications of Aerospace Materials

Below, we discuss the applications of common materials used in aerospace industry:

Leghe di alluminio

- Airframes like the body, wings, and support ribs

- Moving parts like elevators, rudders, and ailerons to control surfaces

- For inside panels and access doors

Leghe di titanio

- Landing gear, as it takes a lot of force

- High-stress parts like wing supports and bulkheads

- Engine parts like compressor blades

Steel Alloys

- Landing gear

- Missile bodies because they can handle high pressure and strong forces

- Great for pressure tanks that hold high-pressure gases or liquids

Superleghe

- Pale di turbina

- Combustor liners

- Turbine disks

Factors to Consider When Choosing Materials Used in the Aerospace Industry

Here are some of the things you need to consider when choosing aerospace materials:

Rapporto forza-peso

If the material is too heavy, it uses more fuel and carries less weight. If it’s not strong enough, it can put the safety of the aircraft at risk.

Resistenza alla temperatura

Aircraft parts go through very hot and very cold temperatures. You need materials that can handle heat from engines and the sun, cold temperatures at high altitudes, and extreme heat during takeoff and reentry.

Resistenza alla corrosione

Aircraft are exposed to things like moisture, salt, and chemicals. So use aerospace materials that won’t rust easily to keep parts safe.

Espansione termica

When materials heat up or cool down, they expand or shrink. In planes, big temperature changes happen often, so you need to choose materials that don’t change shape too much. Otherwise, the parts can warp or break.

Cost & Availability

High-performance and lighter materials may cost more at first, but save fuel in the long run; this is important for commercial airlines trying to keep costs down.

Considerazioni ambientali

Aerospace materials must meet safety and environmental rules. Look for eco-friendly composites and other materials that help lower noise and emissions.

Conclusione

To build better, safer aircraft, you need the right aerospace materials. At DEK, we help you get the most from these materials. Let’s talk about your needs and create the right solution for your project.

Domande frequenti

What challenges do engineers face when choosing materials for aerospace applications?

Balancing the material properties while ensuring cost-effectiveness and compliance with safety standards is a big challenge.

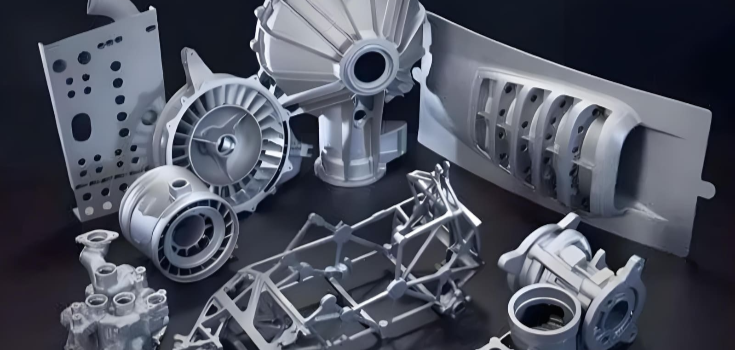

What are the advancements in additive manufacturing for aerospace materials?

Additive manufacturing, or 3D printing, lets you make complex, lightweight parts that were hard to produce before. It also allows the use of new materials and reduces waste by using recycled content.

How do high-temperature alloys improve engine performance in aerospace applications?

High-temperature alloys let engines run hotter, which makes them more efficient and powerful. They also last longer by resisting heat damage and wear.