Metal 3D Printing Service

Le parti vengono stampate sulla base di file di progettazione 3D individuali, consentendo la personalizzazione e la personalizzazione sia funzionale che estetica senza elevati costi di attrezzaggio. Scegliete la stampa 3D in metallo per volumi medio-bassi che richiedono personalizzazione, peso e tempi di consegna.

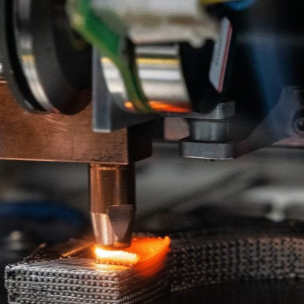

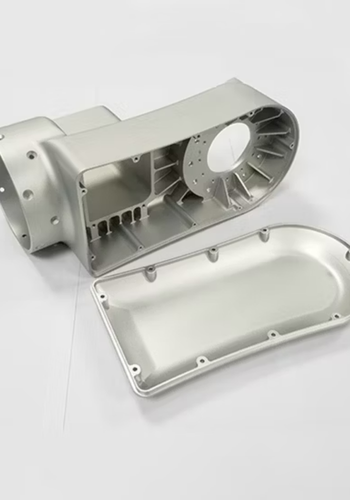

DEK provides comprehensive metal 3D printing services using advanced powder bed fusion technology and high-performance alloys like aluminum and titanium. Unlike many competitors, DEK integrates additive and subtractive manufacturing, in-house finishing, and ISO-compliant quality control. Our engineering expertise ensures optimized designs, faster turnaround, and cost-effective, production-ready parts.

introduzione

High-Precision Stampa 3D del metallo

DEK offers precision metal 3D printing services using advanced powder bed fusion technology, delivering complex, lightweight, and fully functional parts with integrated finishing and ISO-certified quality assurance.

Our facility is equipped with advanced metal printers capable of working with materials like aluminum, titanium, stainless steel, and other performance alloys. From concept to final part, we support customers through the full process, including design optimization, support structure planning, printing, post-processing, and quality inspection. Whether for prototypes or small-to-medium production runs, DEK ensures each part meets industry standards and functional requirements. In addition to printing, DEK offers integrated post-processing services, such as heat treatment, CNC machining, and surface finishing, all performed under strict ISO-certified quality control. Our team provides guidance on design, helping clients reduce material use, improve performance, and shorten production time.

By using both 3D printing and machining, we create high-quality metal parts faster, at lower cost, and with reliable results for industries like aerospace, medical, and automotive.

- Advanced PBF equipment

- Wide material selection

- Integrated finishing solutions

- ISO-certified processes

- Expert design support

- Fast project turnaround

I materiali for Metal 3D Printing

Metalli

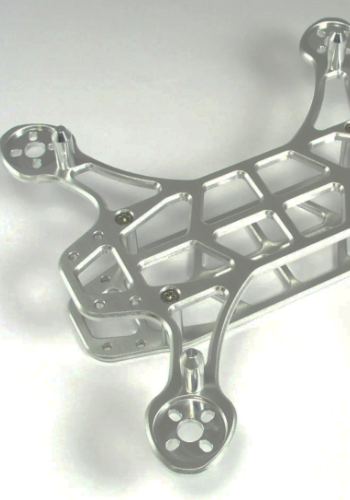

Alluminio

Aluminum is a lightweight, corrosion-resistant metal widely used in metal 3D printing for its excellent thermal conductivity and ease of machining. It is commonly used in aerospace, automotive, and consumer industries where weight reduction is critical.

DEK offers precise aluminum metal 3D printing services that produce parts like housings, brackets, and heat exchangers. Our technology ensures tight tolerances, smooth finishes, and quick turnaround times, making aluminum ideal for both prototypes and production parts.

Lega

AL6061, AL6063, AL5083, AL5052, ecc.

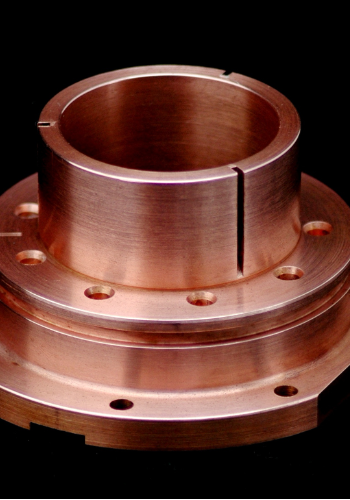

Rame

Copper is valued for its exceptional electrical and thermal conductivity, corrosion resistance, and machinability. It is widely used in electrical components, heat exchangers, and RF devices.

We offer precision copper metal 3D printing services that create intricate, conductive parts such as inductors and heat sinks. Our metal 3D printing ensures dimensional accuracy, smooth finishes, and consistent material performance, making copper ideal for both functional prototypes and end-use components in high-performance applications.

Lega

Rame C101, C110, ecc.

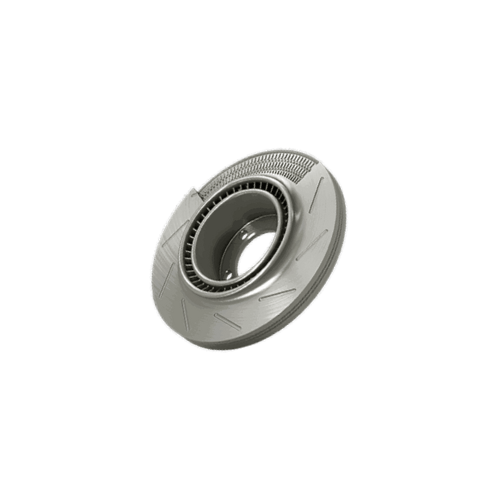

Inconel

Inconel is a high-strength, corrosion-resistant nickel-based metal ideal for extreme environments like aerospace and power generation. Its excellent oxidation resistance allows it to maintain mechanical integrity at elevated temperatures.

DEK specializes in Inconel metal 3D printing, producing complex, heat-resistant parts such as turbine blades and exhaust components. Our advanced metal 3D printing process guarantees precise geometries, durability, and consistent performance for applications requiring strength under severe thermal and mechanical stress.

Lega

Inconel 718, 625, 600, ecc.

Magnesio

Magnesium is one of the lightest structural metals, offering a unique combination of strength, low density, and good thermal conductivity. It is used in aerospace, automotive, and lightweight engineering applications.

DEK provides metal 3D printing for magnesium components, delivering lightweight yet strong parts with intricate designs. Our process ensures dimensional accuracy and repeatable quality for prototypes and end-use applications.

Lega

MgAZ318, MgAZ61B, MgAZ91D, etc.

Acciaio inox

Stainless steel is a versatile metal known for its strength, corrosion resistance, and weldability, used across medical, industrial, and structural applications. It supports hygienic and durable components.

We use metal 3D printing to produce stainless steel parts with tight tolerances and excellent surface finishes. We manufacture intricate parts like surgical tools and mechanical brackets with consistent quality, enabling rapid prototyping and small- to medium-scale production for industries demanding robust metal components.

Lega

Acciaio inox 301, 303, 304, 304L, 316, 316L, ecc.

Titanio

Titanium is a strong, lightweight, and corrosion-resistant metal widely used in aerospace, medical implants, and high-performance engineering. It offers an excellent strength-to-weight ratio and biocompatibility.

DEK provides titanium metal 3D printing services capable of producing complex geometries like surgical implants, brackets, and housings. Our technology delivers parts with precise dimensions, high durability, and smooth finishes, ideal for critical applications where weight savings and material performance are essential.

Lega

Titanio grado 1, grado 2, grado 5, ecc.

Acciaio per utensili

Tool steels are high-hardness metals designed for wear resistance, toughness, and durability, commonly used in tooling, molds, and dies. They withstand high loads and mechanical stresses.

DEK offers metal 3D printing for tool steel parts requiring complex shapes and superior mechanical properties. Our process ensures dimensional accuracy, repeatability, and long tool life, making it suitable for injection mold inserts, cutting tools, and custom tooling components in demanding manufacturing environments.

Lega

Acciaio per utensili A2, A3, D2, S7, ecc.

Immediato e Citazioni precise

Non utilizziamo strumenti di quotazione automatizzati online, perché sono molto imprecisi. Le piattaforme di quotazione online si basano esclusivamente su calcoli basati su importi di taglio e coefficienti fissi, e non tengono conto delle reali sfumature di lavorazione, come la deformazione del materiale dopo il trattamento termico, gli stretti requisiti di tolleranza, la rettifica dopo il trattamento termico, ecc. Di conseguenza, i calcoli automatici dei prezzi possono portare a delle imprecisioni, aumentando i costi.

Ma da DEK potete stare tranquilli!

I nostri preventivi sono convenienti e accurati perché disponiamo di un team di ingegneri meccanici professionisti che esaminano meticolosamente ogni disegno. Questi ingegneri vantano oltre 10 anni di esperienza e possiedono una profonda competenza in materia di programmazione, funzionamento delle macchine, post-elaborazione, proprietà dei materiali e altro ancora. Vi assicuriamo preventivi accurati entro 6 ore.

I nostri vantaggi

Oltre 2300 ingegneri Amore Lavora con noi

Material Flexibility

DEK works with a broad range of metals, including aluminum, titanium, stainless steel, Inconel, cobalt-chrome, and custom metal powders. This material flexibility enables engineers to choose the best metal for strength, weight, heat resistance, or corrosion protection.

Tolleranze strette

DEK achieves excellent precision in metal 3D printed parts, with tolerances typically within ±0.005 mm. This level of accuracy ensures that parts fit and function as intended, even in high-performance applications.

Finiture di superficie personalizzate

DEK offers multiple post-processing options for metal parts, such as polishing, sandblasting, bead blasting, and coating. These finishing processes enhance surface aesthetics, wear resistance, and corrosion protection.

No Order Limits

DEK supports flexible production volumes with no minimum order quantity. Whether you need a single prototype or a low-to-mid-volume production run, DEK adapts to your needs. Explore metal 3D printing without committing to large batch quantities or high upfront manufacturing costs.

Complex Geometry Printing

DEK’s metal 3D printers can produce highly intricate geometries, including internal channels, lattice structures, overhangs, and organic shapes. This design freedom is ideal for lightweighting, fluid flow optimization, and part consolidation.

Produzione economicamente vantaggiosa

Metal 3D printing at DEK reduces overall production costs by minimizing waste, eliminating tooling, and shortening development timelines. Especially for low-to-mid volume orders or complex geometries, additive manufacturing becomes significantly more economical than traditional CNC or casting methods.

Il nostro Processo di ordinazione

Invia RFQ

Inviare RFQ con disegni 2D/3D e requisiti dettagliati tramite e-mail o modulo online.

Recensione e preventivo

Il nostro team di ingegneri esaminerà attentamente ogni disegno e fornirà un preventivo accurato entro 6 ore.

Confermare l'ordine

Confermate il preventivo, i dettagli e il programma di consegna, quindi firmate il contratto.

Produzione

Organizzare il processo di produzione, avviare la programmazione e la lavorazione.

Controllo qualità

Rigoroso controllo di qualità durante la produzione e l'ispezione finale.

Imballaggio e spedizione

Imballare i pezzi, applicare le etichette di identificazione e iniziare la spedizione.

Inviare RFQ 222

Recensione e preventivo

Confermare l'ordine

Produzione

QC

Consegna

FAQ

Metallo 3D Domande frequenti sull'acquisto

Ottenere un preventivo accurato Per i vostri prossimi progetti

Non importa se il vostro progetto è complicato o semplice, se è in metallo o in plastica, riceverete un preventivo accurato entro 6 ore.

Richiedete un preventivo oggi stessoStampa 3D del metallo Approfondimenti

Che cos'è la stampa 3D dei metalli?

La stampa 3D di metalli si riferisce a vari processi di produzione additiva che costruiscono parti metalliche strato per strato a partire da dati di modelli 3D senza i vincoli dei metodi sottrattivi tradizionali. Le tecnologie più comuni utilizzate sono la fusione a letto di polvere, la deposizione a energia diretta e il getto di legante.

Una fonte di calore focalizzata, come un laser o un fascio di elettroni, fonde e fonde selettivamente la polvere metallica o il filo in strati sottili basati sulle sezioni trasversali del modello CAD 3D per costruire un oggetto fisico. È possibile stampare un'ampia gamma di metalli, dall'acciaio inossidabile e il titanio alle leghe di nichel, alluminio e cobalto-cromo. Rispetto alla produzione convenzionale, questo approccio offre una libertà di progettazione altamente innovativa per geometrie complesse, leggere e personalizzate. La stampa 3D in metallo è ideale per la prototipazione rapida, la costruzione di utensili a ponte e la produzione in volumi medio-bassi.

Quali sono i vantaggi della stampa 3D in metallo?

Metal 3D printing enables the production of high-performance components with greater speed, flexibility, and design freedom than traditional manufacturing.

- Lightweight structures

- Reduced material waste

- No tooling needed

- Prototipazione rapida

- Flexible production

- Faster turnaround

- Fewer assemblies

- Strong, durable parts

- Low-volume efficiency

- Optimized material use

- Custom designs

When Do You Use Metal 3D Printing?

Metal 3D printing is great for projects that require quick production, detailed customization, or small batches without the need for molds or tools. For example, in aerospace, it’s used to make engine parts, brackets, and heat exchangers that must perform under extreme conditions. In the medical field, doctors and dentists use it to create custom implants, surgical tools, and prosthetics made to fit each patient perfectly.

This technology is also widely used in the automotive industry to design and test lightweight parts quickly, such as exhaust manifolds or heat shields. In factories, it helps produce useful tools, jigs, and fixtures that support day-to-day manufacturing tasks. Metal 3D printing is also popular in fields like architecture, jewelry, and consumer electronics, where detailed and artistic metal designs are needed. Even in research labs, it’s used to create metal samples for testing and experiments.