- Casa

- Medical Device Prototyping Services

Prototipazione di dispositivi medici Servizi

Our medical device prototyping service provides functional, high-quality models. From simple to complex medical components, we produce on-demand at competitive prices, launching products to market faster through rapid prototyping, bridging tools, and low-volume production.

- Prodotti per la produzione

- Assistenza tecnica 24/7

- ISO 13485 Certification

- Analisi del design per la produzione (DFM)

Medical Device Prototyping and Manufacturing

DEK is a leading manufacturer of high-quality, cost-effective medical device prototypes and custom parts, specializing in CNC machining, injection molding, and 3D printing.

We offer 50+ certified biocompatible and sterilizable materials, paired with expert technical support for medical prototyping. We deliver high-precision custom components—maintaining tolerances of ±0.01mm—to ensure consistent quality and fast turnaround.

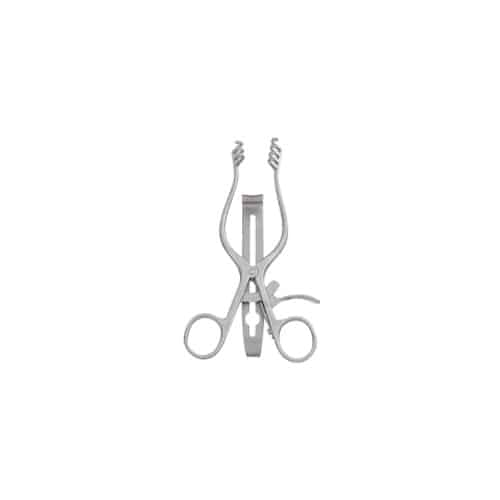

Our company partners with industry leaders to bring new products into the markets of clinical care, diagnostics, research, and rehabilitation. Our success stories include handheld devices, surgical instruments, diagnostic equipment, medical device housings, health monitors, and other medical devices. We have no minimum order quantities and offer solutions for projects of any scale or complexity. Our strict adherence to ISO 13485 ensures that medical prototypes and parts meet design requirements for human safety, size, performance, and durability.

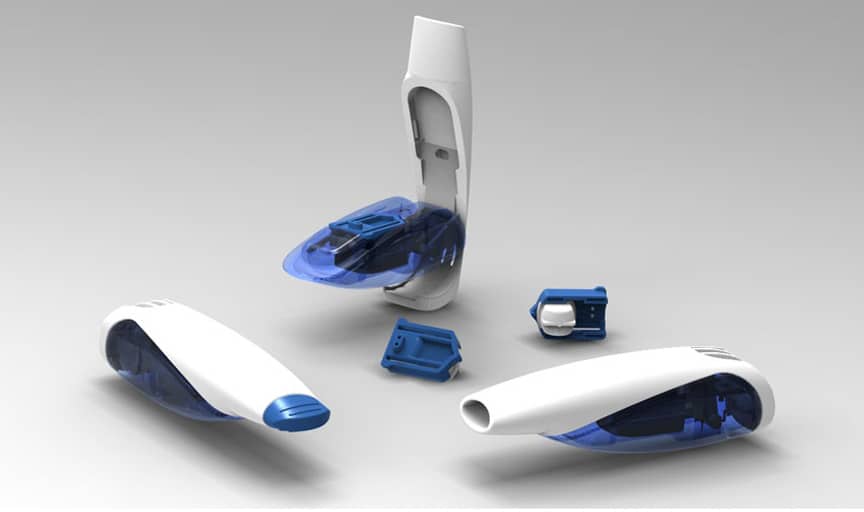

Handheld Device

Vital Sign Monitor

Medical Storage Cabinet

CT Scanner

Alloggiamento per dispositivi medici

Medical Cart

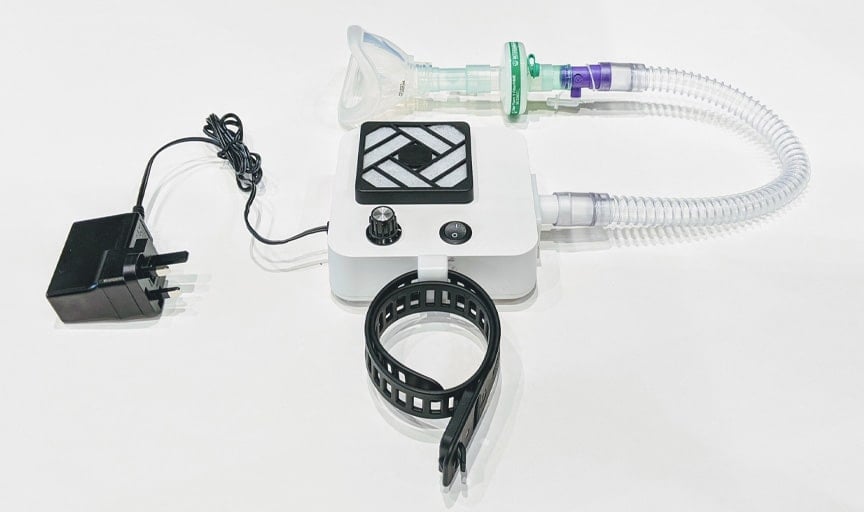

Medical Oxygen Machine

Surgical Instrument

Prototipazione di dispositivi medici Capacità

Lavorazione CNC

DEK has advanced 3, 4, and 5-axis CNC machining to provide product-grade plastics and metals, including ABS, nylon, aluminum, titanium, and stainless steel.

Our engineering and production teams have extensive experience and design flexibility in medical device prototyping and part manufacturing, enabling rapid physical prototyping of complex geometries and accelerated time-to-market. From medical prototypes to lavorazione CNC di piccoli lotti, we can provide you with cost-effective quotes based on market prices.

Stampaggio a iniezione

DEK specializes in medical prototyping and parts via injection molding. We use medical-grade plastics (PE, PU, PP, PC, PS, ABS) and silicone to ensure compliance with strict standards.

Our injection molding process suits rapid prototyping and low-volume production, achieving complex geometries and tight tolerances for medical prototypes functionally validated before full-scale manufacturing. By integrating feedback at every stage, we help bring medical innovations to life, including microfluidic devices, health monitors, and other components.

Lavorazione della lamiera

DEK provides reliable sheet metal medical prototyping and custom fabrication, from precision molding of complex parts to full cutting, shaping, and finishing to meet your needs.

We have a wide selection of metals, including stainless steel, aluminum, titanium, and brass. In addition, we provide surface treatments like painting, plating, anodizing, and polishing to improve corrosion resistance and aesthetics. Meanwhile, we offer laser cutting and engraving to improve accuracy. Previous projects include diagnostic equipment, housings, and cabinets.

Colata sotto vuoto

DEK specializes in vacuum casting for medical device components, including displays, diagnostic housings, wearables, surgical instruments, and prosthetics.

We offer more than 50 certified materials and flexibility to produce the medical device prototype or part you need, ensuring the part meets project requirements. With advanced equipment and vacuum casting technology, we quickly manufacture complex shapes and test the feasibility of the design before producing the part. Prices are cost-effective for low-volume manufacturing.

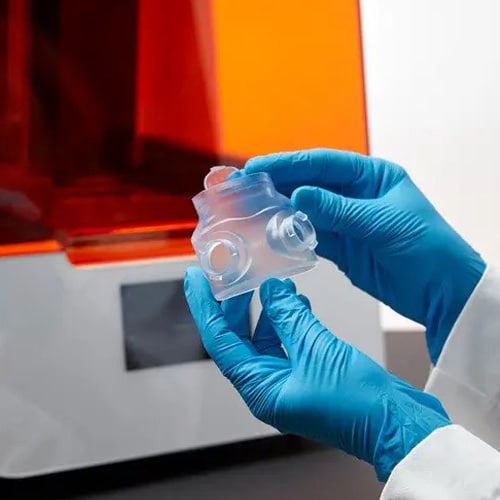

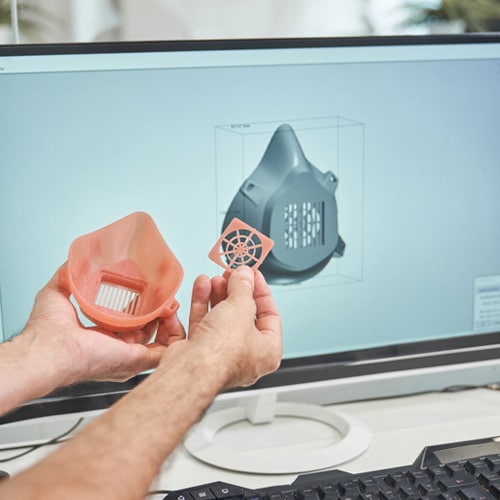

Stampa 3D

DEK's 3D printing accelerates medical prototyping and R&D, allowing designers to iterate, test, and adjust designs rapidly.

We provide over 50 certified materials. We achieve complex geometries, reduce design constraints, and customize the medical components you need. We streamline production with flexible manufacturing cost-effective for medical device prototyping and low-volume production. Our engineering team provides fast, efficient solutions for medical industry applications.

I materiali

Prototipo di dispositivo medico Opzioni di materiale

Acciaio inox

DEK machines SUS304, 316, 430, and 2205 into corrosion-resistant medical prototypes and components to your specifications.

Policarbonato (PC)

We machine durable, sterilizable PC into high-quality medical prototypes and components to your requirements.

Titanio

We machine Grade 1, 2, and 5 titanium into precision, biocompatible medical implants and devices.

Silicone

We manufacture precision biocompatible silicone medical components, seals, and fluid management devices.

Poliuretano (PU)

DEK machines biocompatible polyurethane into high-quality, flexible medical supports and handheld devices.

Polietilene (PE)

We manufacture biocompatible polyethylene medical disposables, packaging, and device housings to your standards.

Processo

Prototipazione to Production

Prototipazione

Using high-fidelity prototyping to support medical device innovation is an important part of our process. After working with you to analyze the feasibility of medical device prototyping, our engineers will select the right materials and processes to create a prototype or component that will look like the final product for your application.

- Accurate prototypes with complex geometries

- Production-grade materials and rapid design changes

- High-fidelity prototypes that are close to the final component

Engineering Validation and Testing

After engineering testing and verification of performance requirements, you can easily identify design issues and make corrections to the design, quickly make the appropriate detail changes to the functional medical device prototype, and finally we create a functional prototype that resembles the final product.

- Assistenza tecnica 24/7

- High-precision prototyping

- Optimized design and material selection

Design Validation and Testing

From fluid management systems to drug delivery devices to respiratory aids, these medical components often have highly complex designs. DEK validates the functionality and appearance of your medical prototypes in the most efficient way possible, ensuring that the necessary design iterations are made to save production time and costs.

- Quality Surface Finishes Options

- Functional and cosmetic validation

- Quality prototypes for market testing

Production Validation and Testing

Make your medical device prototypes ready for volume production using medical-grade materials and appropriate processing. Our technicians will build a prototype of the product that matches your design, allowing you to accurately assess manufacturability and suitability for scale production.

- Tight tolerances on prototypes and critical components

- Biocompatible, non-toxic or sterilizable materials

- Quality control with CMM or on-machine inspection

Produzione di massa

DEK has many years of experience in the medical field. We manufacture medical device prototypes, medical device components, surgical instruments, handheld devices and fixtures for a wide range of customers. From early prototypes to final parts, we can realize the most complex designs and help your project move quickly from the product testing stage to full production of end-use medical components.

- Medical-grade materials

- Precise quality requirements

- Superior post-processing operations

- Precision machining with tight tolerances

- High quality medical device prototypes and custom parts

Perché scegliere I nostri servizi

La produzione in un'unica soluzione di prototipi di alta qualità vi fa risparmiare tempo e denaro.

Capacità ingegneristiche

Produzione rapida

Finiture di superficie

Assemblaggio di precisione

Controllo qualità

Imballaggio e trasporto

Il nostro Processo di ordinazione

Invia RFQ

Inviare RFQ con disegni 2D/3D e requisiti dettagliati tramite e-mail o modulo online.

Recensione e preventivo

Il nostro team di ingegneri esaminerà attentamente ogni disegno e fornirà un preventivo accurato entro 6 ore.

Confermare l'ordine

Confermate il preventivo, i dettagli e il programma di consegna, quindi firmate il contratto.

Produzione

Organizzare il processo di produzione, avviare la programmazione e la lavorazione.

Controllo qualità

Rigoroso controllo di qualità durante la produzione e l'ispezione finale.

Imballaggio e spedizione

Imballare i pezzi, applicare le etichette di identificazione e iniziare la spedizione.

Inviare RFQ 222

Recensione e preventivo

Confermare l'ordine

Produzione

QC

Consegna

Prototipazione di dispositivi medici Domande frequenti sull'acquisto

Ottenere un preventivo accurato Per i vostri prossimi progetti

Non importa se il vostro progetto è complicato o semplice, se è in metallo o in plastica, riceverete un preventivo accurato entro 6 ore.

Richiedete un preventivo oggi stessoConoscenza of Medical Device Prototyping

What is Medical Device Prototyping?

Medical device prototyping is the process of creating functional samples based on a product's design and specifications for testing, evaluation, and business demonstration. These prototypes help manufacturers check the efficiency and feasibility of the design and determine if any changes are needed before the product is put into high-volume production and market distribution.

3D designs may seem ideal and revolutionary, but in reality, problems come to the fore when taken in hand. Through prototype testing, you can get quick feedback to ensure that the final product will meet medical requirements and safety standards.

If you want to know more about medical device prototyping, you can read this blog about a guide to medical device prototyping qui.

Advantages of Medical Device Prototyping

Rischio ridotto: Medical device prototypes reduce the risk of mass production by identifying design and functional defects as early as possible.

Risparmio sui costi: Risolvere i problemi durante la fase di prototipazione garantisce un processo di produzione economicamente vantaggioso.

Migliorare la qualità: Attraverso test e perfezionamenti iterativi, la prototipazione assicura che il prodotto finale sia esteticamente gradevole e funzionale.

Comunicazione potenziata: La prototipazione favorisce una migliore comprensione e coordinazione tra i membri del team e le parti interessate.

Faster Development: Prototyping can streamline the development process by allowing teams to iterate quickly and improve designs based on real-world testing.

Applications of Medical Device Prototyping

Respiratory Equipment: Develop prototypes of adjustable ventilators to meet the ventilation needs of different patients, enhance the accuracy of oxygen delivery, and improve the quality of life of patients with chronic lung disease.

Monitors: Design prototypes of novel multi-parameter monitors to monitor heart rate, blood oxygen and respiratory rate in real time to ensure patient safety during surgery and critical care.

Wearables: Explore prototypes of wearable health monitoring devices that collect ECG and activity data through sensors to help users track their health status and detect abnormalities in a timely manner.

Imaging devices: Develop prototypes of high-resolution ultrasound or CT devices to optimize imaging quality and processing speed, improve diagnostic accuracy, and aid in early disease detection.