- Casa

- Oil & Gas

High Quality Custom Oil & Gas Parts Manufacturing

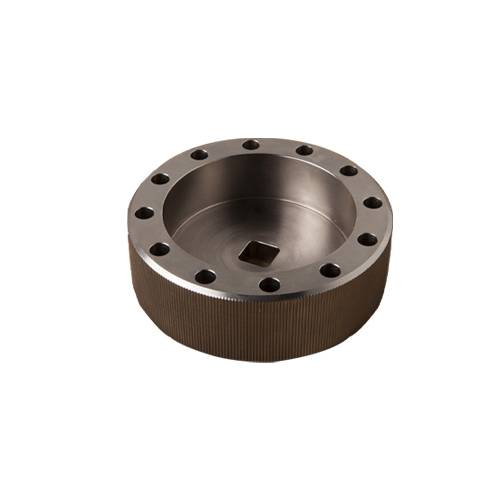

DEK has been specializing in the precision manufacturing of machined parts for the Oil & Gas industry, and we offer high-quality, durable components with industry-leading speed to customers around the world at cost-effective prices. We can quickly machine complex parts with tight tolerances of +/- 0.005mm, a wide range of production grade materials, and surface finish options. Get instant quote!

- Competitive Price & Reliable

- 24/7 Engineering Support & DFM

- ISO 9001:2015 Certified.

- Rapido giro, breve tempo di consegna, non MOQ

Precision Parts Manufacturing in the Industria del petrolio e del gas

DEK is renowned for our outstanding quality and exceptional customer service, providing precision machining of custom parts for the oil and gas industry. Our parts are reliably applied in the high-speed, high-volume, and corrosive environments commonly found in this industry.

As an ISO 9001-certified manufacturer, DEK possesses top-tier machining capabilities, achieving precision tolerances as tight as ±0.005mm. We strictly adhere to industry standards such as API and NACE, and specialize in machining specialty corrosion-resistant materials like Hastelloy, Inconel, and Monel, ensuring that every part processed by DEK delivers exceptional performance and durability.

Additionally, we offer surface treatments such as anodizing, QPQ, electroplating, nitriding, and Passivation. Our typical applications include MWD/LWD parts, drill string components, downhole motors, casing, and cementing accessories. We provide a fast, transparent quoting process and clear production scheduling, along with CMM inspection reports, FAI reports, and material certificates. Contact us today to reduce your total cost of ownership (TCO).

Turned Part

Turned Part

Machined Part

Albero di precisione

Albero di precisione

Gancio per tubi

Turned Part

Oil & Gas Component Capacità di produzione

Lavorazione CNC di precisione

DEK offers fast, accurate, and reliable CNC precision machining. Our strict tolerances can reach ±0.005mm, making us ideal for precision leak-proof rotation chuck parts, seal parts, casing heads, flanges, and connectors.

We specialize in precision parts machining for the oil and gas industry, with expertise in 5-axis machining of complex parts. We offer rapid prototyping services and free DFM analysis to reduce costs. Whether you need a functional prototype or are seeking a reliable partner for small-batch production, DEK provides flexible and efficient solutions.

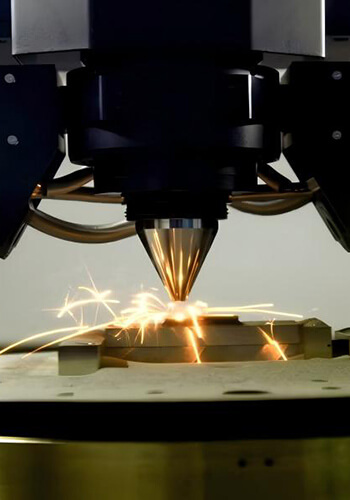

Stampa 3D industriale

DEK offers high-quality additive manufacturing technologies, including metal 3D printing, SLA, SLS, and FDM. We help you create rapid prototypes at low cost and produce high-precision, durable, corrosion-resistant parts.

We offer a variety of metals and plastics, including stainless steel, Inconel, and PTFE, for printing Inconel 718 turbine blades, mixed nozzles, or heat exchanger components. Additionally, we can provide surface treatments as required for your project, such as heat treatment, nitriding, QPQ, and PTFE coating.

Lavorazione della lamiera

DEK specializes in manufacturing high-quality custom sheet metal parts for the oil and gas industry. From equipment skids to electrical control cabinets, we provide reliable structural support and protection for your core equipment.

We offer a variety of sheet metal materials, including aluminum, stainless steel, steel, brass, and copper. From instant quotes to rapid production, you can obtain over 300 high-quality sheet metal parts in just a few days. Additionally, we provide surface treatment options to meet your parts' high-demand requirements.

Stampaggio a iniezione di plastica

DEK offers high-performance injection molding for the Oil & Gas industry. We specialize in advanced polymers like PEEK, PPS, PTFE, and PEI for critical seals, insulators, and wear components.

Our expert mold design and rigorous process control ensure exceptional dimensional accuracy and tight tolerances. We focus on material stability and creep resistance, guaranteeing reliable, consistent components for your most critical high-pressure, high-temperature (HPHT) applications.

I materiali

I materiali Opzioni

Acciaio inox

This high-performance metal is renowned for its excellent corrosion resistance, high strength, and resistance to high and low temperatures, making it the material of choice for offshore platform structural components, fasteners, impellers, and shafts.

Acciaio al carbonio

Carbon steel has high strength, excellent workability, and weldability. It is widely used in the oil & gas industry and is ideal for manufacturing pressure-bearing components, structural parts, and downhole tools. In addition, we also offer DLC coating and PVD coating.

Acciaio legato

Alloy steel is a high-strength, high-temperature resistant, and wear-resistant metal. It is the preferred material for drill pipes, flanges, tubing heads, high-pressure fasteners, and connectors, and it has excellent low-temperature impact toughness and good machinability.

Inconel

Inconel is a nickel-chromium-based superalloy with outstanding high-temperature strength and creep resistance, superior corrosion resistance, and extreme temperature adaptability. It is ideal for use in subsea Christmas trees, turbine blades, high-temperature bolts, and springs.

Immediato e Citazioni precise

Non utilizziamo strumenti di quotazione automatizzati online, perché sono molto imprecisi. Le piattaforme di quotazione online si basano esclusivamente su calcoli basati su importi di taglio e coefficienti fissi, e non tengono conto delle reali sfumature di lavorazione, come la deformazione del materiale dopo il trattamento termico, gli stretti requisiti di tolleranza, la rettifica dopo il trattamento termico, ecc. Di conseguenza, i calcoli automatici dei prezzi possono portare a delle imprecisioni, aumentando i costi.

Ma da DEK potete stare tranquilli!

I nostri preventivi sono convenienti e accurati perché disponiamo di un team di ingegneri meccanici professionisti che esaminano meticolosamente ogni disegno. Questi ingegneri vantano oltre 10 anni di esperienza e possiedono una profonda competenza in materia di programmazione, funzionamento delle macchine, post-elaborazione, proprietà dei materiali e altro ancora. Vi assicuriamo preventivi accurati entro 6 ore.

Perché scegliere I nostri servizi

La produzione in un'unica soluzione di pezzi di alta qualità consente di risparmiare tempo e denaro.

Capacità ingegneristiche

Tempi di consegna rapidi

Finiture di superficie

Controllo qualità

Assemblaggio di precisione

Packaging and Logistics

Il nostro Processo di ordinazione

Invia RFQ

Inviare RFQ con disegni 2D/3D e requisiti dettagliati tramite e-mail o modulo online.

Recensione e preventivo

Il nostro team di ingegneri esaminerà attentamente ogni disegno e fornirà un preventivo accurato entro 6 ore.

Confermare l'ordine

Confermate il preventivo, i dettagli e il programma di consegna, quindi firmate il contratto.

Produzione

Organizzare il processo di produzione, avviare la programmazione e la lavorazione.

Controllo qualità

Rigoroso controllo di qualità durante la produzione e l'ispezione finale.

Imballaggio e spedizione

Imballare i pezzi, applicare le etichette di identificazione e iniziare la spedizione.