If you’re wondering how end milling works, or you’re on a mission to carry out an end milling project soon, or wish to learn more about the tool used, this blog post is for you.

We've provided all the crucial information you need to know. Now let’s read on.

Che cos'è la fresatura di testa?

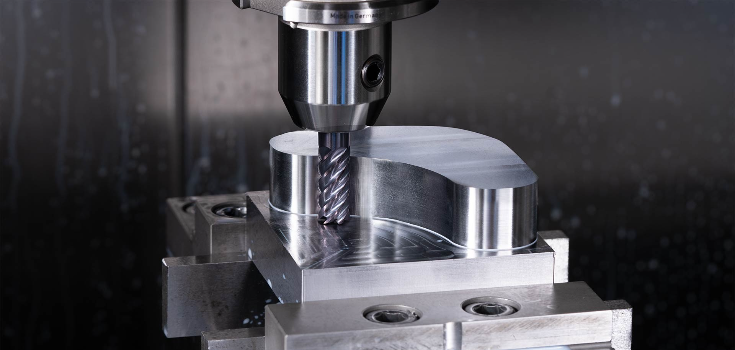

End milling is a fabrication technique that involves using a multi-directional, rotating tool known as an end mill to cut or form a shape in the machining material.

End mill tools are typically cylindrical in structure. They are designed with sharp milling edges on both their bodies and tips, allowing the equipment to cut material from various axes and directions with ease.

Different machining profiles I’ve found end milling helpful include contours, die cavities, slots, 3D profiles, and lots more

Why is End Milling Important?

Fresatura finale is essential in machining, as it enables the processing of a wide range of part designs, from simple to complex, with a single machine and tool setup.

This is particularly feasible due to the specific equipment design and CNC technology that automate and allow for accurate precision.

With the technique, I most often achieve precision as tight as ±0.05mm. This improves cutting efficiency as there’s no need for further milling procedures.

Additionally, I can work with a range of materials, including metal alloys, high-performance plastics, and composites, by utilizing the most suitable end mills for each material.

Another significant benefit is the ability to complete other procedures, such as roughing and finishing, with a single CNC milling setup. This helps me eradicate the need for multiple material positioning, thereby enhancing accuracy.

How Does the End Milling Process Work?

Our engineering team performs end milling operations according to the step-by-step process outlined below.

Component Design and CAM Programming

The first step we follow is to build a model design for the component using CAD software.

This is done with exact precision and dimensions. This design is then uploaded to a CAM software where the milling tool paths, including the profiles and contours, are determined.

After the testing and simulation process is completed, the tool paths are converted into G-code and transferred to the CNC machine, preparing it for milling.

Tool Set Up

The next step is setting up the tool. Here, the suitable end mill is placed firmly into its holder and attached to the spindle.

The workpiece is also secured with the aid of a clamp or vise to eliminate disruption or vibrations. Care is taken to ensure proper alignment and precision.

Choose Milling Parameters

Here, we select the machining parameters, including feed rate, spindle speed, depth, and others. Deciding on the type of cooling method is also done here. Depending on the material we are working with, we can use either water- or oil-based coolant.

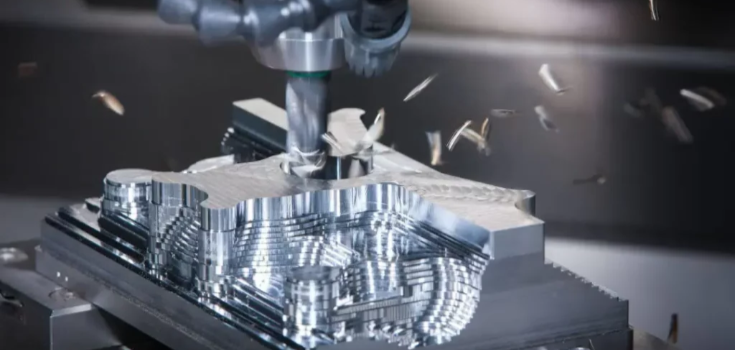

Actual Milling Process

Once the other steps are completed, including uploading the Codice G to the CNC machines, the milling process begins with the spindle rotating the end mill cutter to form a shape or create accurate cuts.

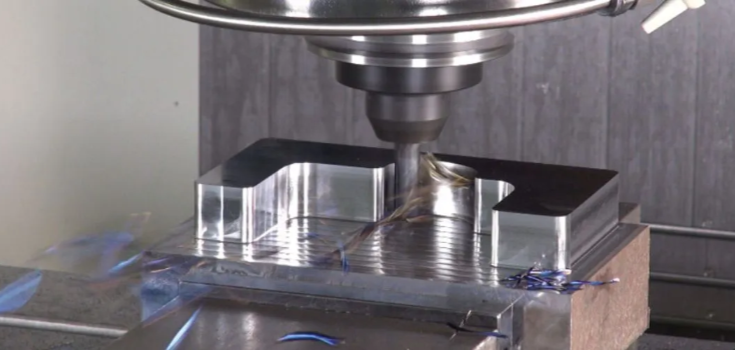

Finishing Procedure and Inspection

Lastly, the component undergoes a final finishing treatment. Deburring is complete, and a quality CMM check is performed to ensure precise accuracy.

Types of End Milling Based On Tool Geometry

Over the years, with our machining experience, we’ve used a wide range of end mill cutters. These are categorized based on tool geometry, flutes, material, helix angle, and other factors, and are explained below.

Frese a candela quadrate

These are the most versatile and popularly used. They are designed with flat milling ends that enable them to achieve 90-degree corners in the material. They are suitable for creating slots, contours, pockets, shoulders, and more, and support a variety of material machining.

Keyway End Mills

They are designed particularly to create narrow key slots found in mechanical structures. Keyway end mills are essential for producing keyways in gears, pulleys, and other similar components. Due to their unique geometry, they are capable of creating precise, fine cuts in steel and many other materials.

Corner Radius End Mills

These end mills possess rounded tips rather than sharp corners, which helps them eliminate chipping and wear. The tool's unique design enhances its durability, provides fatigue resistance, and facilitates accurate and consistent machining.

Corner Rounding End Mills

These end mills are designed to create rounded, fine edges on machined materials or components. With this, the component becomes less susceptible to cracking or damage. They are also widely used for machining parts that require exceptional resistance to stress and load.

Frese a sfera

These cutters feature circular or ball-end tips, allowing them to create contour or curved parts conveniently. They help create dies, molds, and other complex shapes. Due to their spherical end, they provide a smooth finish and reduce tool wear.

V-Bit End Mills

V-bit end mills are designed with a V-shaped tip and, as such, are used for machining procedures such as engraving and chamfering. They are suitable for materials such as plastics, wood, and certain metals, and are used in milling tasks that involve creating logos, lettering, and other artistic features.

Fishtail End Mills

Fish tail end mills feature a flat edge with a unique, slight upward curve, resembling the tail of a fish. With this design, the tool remains firm, eliminating splintering while milling on a surface. As a result, clean, highly accurate edges are achieved on the machining material. They are suitable for machining plastic, wood, or composite parts requiring smooth, precise edges.

Dovetail End Mills

Dovetail mills possess edges with angles that allow them to form dovetail slots. They are instrumental in producing components used in jigs, slides, and other similar mechanical structures. Due to their design, they ensure precise machining of slots used to lock components together.

Frese a candela Torus

The torus end mill is designed with a leveled bottom, along with a small circular tip. With this design, they retain their strength better than square end mills and are particularly useful for semi-finishing operations.

Frese per sgrossatura

Roughing end mills are capable of removing large material portions from a surface as quickly as possible. They have serrated designs that enhance machining efficiency, and they are thus used when part removal or cutting is more important than the surface finish. They can also work on extremely tough material without deforming and can mill heavy stock into smaller elements.

Finishing End Mills

As the name implies, finishing end mills are used at the finishing stages of an end milling process. These tools typically feature fine, smooth cutting tips that produce enhanced surface quality in the components. When finishing, appearance and precision matter; this tool is the ideal choice.

Frese coniche

These are specialized mills with a cone-like body. The cone shape of these mills is designed to be narrower toward the tip. With this design, they maintain their strength over a long period and can be used for milling deep cavities, molds, contours, and angled walls, among other applications.

Frese a candela

Drill mills enable multiple operations with a single tool. It has a sharp tip that carries out its drilling purpose. Additionally, the flutes enable it to perform milling and slotting operations. As such, it reduces the need to replace tools, as it performs two separate functions.

Types of End Milling Based on Flutes

2 Flutes End Mills

These possess two milling edges and an extensive chip space. They are used for cutting mild materials, such as aluminum, and milling materials quickly and efficiently, preventing clogging.

3 Flutes End Mills

These also provide clean cutting with additional edge durability. They are also suitable for materials like aluminum and provide a better surface finish compared to 2 flutes.

4 Flutes End Mills

These are suitable for tougher materials, such as steel, as they have a more potent and durable edge. They provide a smoother surface finish and are typically used for parts that require higher accuracy.

5 Flutes End Mills

These have 5 flutes, resulting in a smoother surface finish. They are also suitable for more rigid materials, have a longer service life, and support high-depth axial cutting.

Multi Flutes (5 or more flutes)

These have more than five flutes, offer the best finishing, but evacuate less material in a pass. They are also used for hard metals and parts that require exceptional dimensional accuracy.

Types of End Milling Based on Tool Material

High-Speed Steel (HSS) End Mills

These are suitable for mild metals and plastics, and are suitable for low-speed machining. They are pretty economical and flexible.

Cobalt Tools

Cobalt tools have greater strength compared to HSS and can withstand higher temperatures. They are ideal for harder materials, such as stainless steel, and can withstand high-speed machining without wearing out.

Solid Carbide End Mills

These are stronger tools that maintain their strength even at 800 degrees Celsius. They are suitable for high-speed and tough material machining, providing exceptional accuracy.

Micro-grain Carbide End Mills

They contain carbide elements, which give them more durability. They are also suitable for high-speed machining and for exact parts.

PCD (Polycrystalline Diamond) and DLC-Coated Carbide Tools

They are suitable for machining non-metals, such as graphite, and have excellent edge strength, making them suitable for large-scale batch manufacturing processes.

Types of End Milling Based on Coating

Nitruro di titanio (TiN)

This helps improve the service life of tools by up to 30%, making them suitable for metals such as steel and copper, while enhancing strength and reducing friction.

Carbonitruro di titanio (TiCN)

These are used for tougher metals, such as stainless steel. The coating enhances thermal resistance, improves durability, and reduces wear and tear.

Aluminum Titanium Nitride (AlTiN) and AlTiCrN Coatings

They are typically used in high-speed machining. They also enhance heat resistance and are suitable for milling hard steel.

Carbonio simile al diamante (DLC)

DLC provides exceptional surface finishing that eliminates friction. They are perfect for materials like alluminio and plastics.

CVD Diamond

CVD diamond coatings provide additional strength and resistance to wear. They are suitable for cutting abrasive materials, such as composites and other hard-to-cut materials.

Types of End Milling Based on Helix Angle

Low Helix (~30°)

This helix angle is best suited for hard materials, such as cast iron. They are ideal when strength and stability are a priority, but may result in rougher finishing.

Medium Helix (~40°)

They are versatile and work well with a wide range of materials. They offer better surface finish and material removal.

High Helix (>45°)

A high helix angle is perfect for mild materials like aluminum. They provide precise, fast cutting, leaving a smooth surface finish.

Variable Helix (e.g., 35°–42°)

This helps eliminate vibration and distortion in high-speed milling. They provide better finishing and offer an extensive service life.

Specialty End Mills

Corner-Radius–Plus–Rougher

They offer roughing and finishing purposes. They cut material quickly with a rounded corner, eliminating stress and breakage.

Long-Reach or Reduced-Shank Tools

These have a long, slimmer body that allows deep cutting. They are designed for hard-to-reach areas, and they retain their strength and precision while milling these parts.

Compression Cutters

Compression cutters are ideal for cutting composites, wood, and other materials. They ensure that the top and bottom tips remain smooth during milling.

T-slot and Woodruff Cutters

These are used to create special shapes in parts. Suitable for T-slots, grooves, and keyways for structures requiring precise accuracy.

Modular “Switch-Blade” End Mills

These end mills allow for easy replacement of cutting blades, improving work efficiency and reducing costs. When a cutting blade wears out, it’s quickly replaced, enabling fast machining.

Solid vs. Indexable End Mills

Solid end mills are suitable for machining small to medium components. They are usually rigid and strong, enabling exact milling processes with quality surface finishing. Solid end mills don’t have replaceable inserts, and as such, the entire tool must be changed or sharpened when it wears out.

Indexable end mills are suitable for heavy machining activities and typically come with a replaceable carbide insert, allowing for improved machining efficiency as the insert wears. They are suitable for roughing procedures rather than finishing.

Choosing the Right End Mill For Your Project

For optimal results, it’s essential to select the correct end mill for your project. Firstly, I consider the materials I’m working with; softer materials, such as alluminio, require fewer flutes and high helix tools. For rigid materials, carbide and tools with 5 or more flutes will be suitable.

I also check the kind of operations at hand, whether it is roughing or finishing. While the roughing tool cuts material fast, the finishing tool focuses on surface quality. As such, I balance the tool geometry, material, and coating based on the operation.

Fattori da considerare nella scelta di una fresa a candela

Material of the Workpiece

Considering the hardness of the material, mild material like aluminum and soft plastics works well with fewer flutes and HSS. Materials like acciaio are ideal with carbide and 4 flutes or more.

Geometria dello strumento

The component profile definitely determines the tool geometry to go for. Square ends are used for flat slots and pockets, and ball end mills are used for curved surfaces, molds, and dies.

Milling Operation

Whether the milling operation is more about roughing or finishing is another factor. Roughing tasks require a roughing geometry end mill tool and vice versa.

Kind of Coating

Coatings like TiCN and TiN, etc, help provide protection against heat and enhance tool service life. However, considering the workpiece material is also crucial in this case.

Advantages of End Milling

Versatilità

The end milling process can achieve several machining operations, such as slotting, roughing, and contouring, with just one setup. With this, efficiency is enhanced while reducing production time.

Alta precisione

The machining process is capable of achieving a tolerance level of up to ±0.005mm, even in intricate and complex shapes. With the CNC procedure, accuracy is even more enhanced.

Quality Surface Finish

With the proper parameters and tool setup, end milling provides a smooth surface finish that requires no further processing. With finishing end mills and the correct flute tool, smooth, polished surfaces can be obtained.

Complex 3D Designs

End mills can be used to create various 3D designs that can't be achieved with traditional or standard cutters. Molds, slots, dies, and other intricate shapes can be seamlessly milled with this procedure.

Variety of Tool Options

There are several types of end mills. With this, engineers can easily select the one that best suits a project or use as many as possible. This, in turn, improves production efficiency.

Disadvantages of End Milling

Expensive Tool Cost

Investing in good-quality end mills can be expensive. While they may have a long lifespan, maintaining them can even add to the cost.

Tool Wear

When consistently used in machining hard materials, it could wear out. This, in turn, affects the surface finish and accuracy of the component formed.

Complessità del set up

Setting the material in place, determining cutting parameters, and using fixtures all require experts to ensure accurate machining. An incorrect setup can cause vibration and affect dimensional accuracy.

End Milling vs Other Milling Methods

End Milling vs Face Milling

The main difference between end milling and face milling is that end milling enables cutting through its edges and sides from multiple directions, and as such, is suitable for deep slots and 3D complex parts. Face milling, on the other hand, utilizes only the cutting tool edge for milling, allowing for quick cutting of flat surfaces.

Another distinguishing feature between face milling and end milling is that face milling offers better surface quality, while the latter focuses on intricate geometry designs.

End Milling vs Drilling

While drilling is primarily used to form round holes in parts with the aid of a drill bit, end milling can cut in multiple directions, both vertically and horizontally, and can also create exact holes.

End Milling vs Traditional Milling

Traditional milling basically cuts flat, plain surfaces, while end milling can work on complex shapes and cut from different directions. End milling also achieves accurate precision and superior surface quality compared to conventional milling.

End Milling vs Slab Milling

While a slab milling cutter is used in machining large, flat material surfaces, it has a wider cutter and is mainly used for roughing jobs. In contrast, end milling focuses on accurate, intricate designs, utilizing a narrow cutter that machines contours and corners.

Applicazioni della fresatura di testa

Industria aerospaziale: End milling is used to create critical precision components, such as turbine blades, brackets, and wing ribs.

Automotive Industry: Valuable in creating engine blocks and gear parts, which require consistent reliability.

Medico: Used in fabricating prosthetic components, surgical equipment, implants, etc, which must meet exact dimensional accuracy.

Elettronica: Essential in producing heat sinks, casings, and parts requiring exceptional heat resistance.

Marina: Used in making propellers and housing that must perform well in severe environmental conditions.

DEK: Your Best Partner for Milling Projects

DEK is your reliable go-to partner for all end milling and related projects. We have advanced technology facilities, including CNC machines and tools, a wide range of materials, and an expert team of engineers, which enable us to deliver swiftly and effectively worldwide. Contattateci now to get started.

Conclusione

This comprehensive guide provides all the information you need to know about end milling, from its various types to how it works and more, which I’m sure will be helpful for you in carrying out a successful milling project.

Domande frequenti

Si può forare con una fresa?

Yes, we can drill with an end mill. However, they aren’t suitable for very deep holes, such as those that a drill bit can reach.

Side milling vs end milling, what are the differences?

Side milling cuts material mainly from its sides to create a smooth, vertical, flat surface, whereas end milling removes material in multiple directions, both vertically and horizontally, with its tip and sides, to form curves and complex shapes.

Which end mills are best for stainless steel?

End mills with 4 flute or more, solid carbide made, and those with TiCN or AlTiN are best for stainless steel due to enhanced strength and ability to withstand heat.