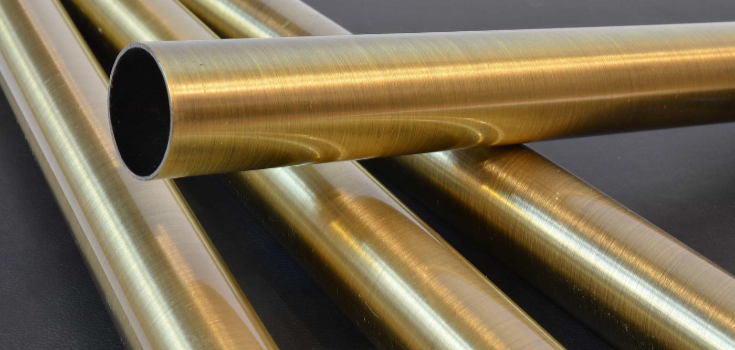

CNC machining brass is a great option when you need high-quality, precise parts. Brass is easy to cut, gives a smooth finish, and doesn’t damage your tools quickly. That makes it a favorite material for machining.

In this guide, you’ll learn what CNC machining brass is, its advantages, the properties and types of brass, and a lot more. If you want to save time and get clean results, this guide will help you get there.

Che cos'è la lavorazione CNC dell'ottone?

CNC machining brass means using computer-controlled machines to cut, shape, and form brass parts. These machines are very accurate and can make detailed and complex parts with ease.

Brass is composed of copper and zinc. It’s popularly used in machining because it’s easy to work with, resists rust, and conducts electricity well.

Advantages of CNC Machining Brass Parts

There are many benefits of CNC machining brass, and some of these are the following:

High Precision & Accuracy

You program the machine with G-code, and it follows the code exactly. Your parts come out the same every time.

Facile da lavorare

Brass cuts smoothly. You can make complex shapes faster, your tools last longer, and you spend less on production.

Economicamente vantaggioso

Brass CNC machining delivers high-quality parts without a high price tag. You save money on materials and machine time.

Rust Resistance

Brass stands up to moisture and water without corroding. Your parts stay strong and last longer in a damp or wet environment.

Versatilità

You can tweak the combination of copper and zinc to get different strengths, colors, or other traits. That means you can customize brass to your exact needs.

Good Conductivity

Brass moves heat and electricity well. If you need electrical connectors or heat-dissipating parts, use brass.

Fast Production

Macchine CNC work quickly and run unattended. You get your parts sooner and can meet deadlines.

Nice Appearance

Brass has a warm, golden shine that looks great on visible parts. Your components can be both functional and attractive.

What Properties of Brass Make It Ideal for CNC Machining?

Brass has several properties that make it a great choice for CNC machining, and here are some of them:

| Proprietà | Ottone |

| Punto di fusione | 885 to 890 °C |

| Densità | 8.5 g/cm³ |

| Modulo di elasticità | 97 GPa |

| Conduttività termica | 115 W/m·K |

| Resistività elettrica | 6.3 × 10⁻⁸ Ω·m |

Conduttività termica

Brass contains copper, which is a good conductor. That’s why it is a good choice for electrical or heat-related applications.

You can also use EDM as part of the CNC machining process, as it works well with brass and helps you cut parts faster and more accurately.

Altamente lavorabile

Brass is one of the easiest metals to machine. The lead in its alloy makes it more flexible and easier to cut.

Because it’s so machinable, you can get good results even if you’re still learning. That’s a big reason why many machinists choose brass for CNC projects.

Strength and Hardness

Even though brass is easy to machine, it’s still strong and durable. It might not be as strong as steel, but it holds up well and is tough enough for many jobs.

Some brass types include aluminum, which adds strength by forming a hard layer on the surface. You will need to use special tools like carbide cutters when machining this stronger type of brass.

Malleabilità

Brass is easy to shape; that’s why it’s perfect for CNC machining. You can bend or form it into different shapes without cracking it.

Brass gets this quality mainly from the copper in it. The more copper a brass alloy has, the easier it is to shape. That’s why you’ll find brass useful when making custom parts with complex designs.

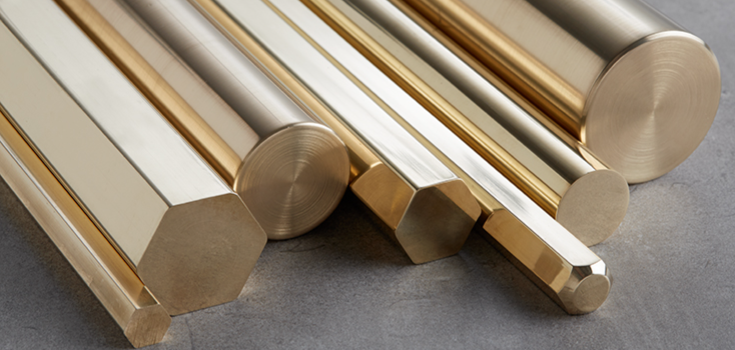

Common Types of Brass Alloys Used in CNC Machining

Below are the most commonly used types of brass alloys, as well as their advantages and disadvantages.

Ottone C230

C230 is called the red brass because of its reddish color. It’s made of about 85% copper and 15% zinc. It’s softer than other types but still strong.

You’ll like using C230 if you need something that resists water and doesn’t rust easily. That’s why it’s often used in plumbing, roofing, jewelry, and decorations.

Pro:

- Doesn’t rust or corrode easily

- Easy to bend, shape, and join (soldering or brazing)

- Nice color for decorative parts

Contro:

- Not as easy to machine as C360

- Softer so it can get scratched or dented

Brass C260

C260 has a nice yellow color and is easy to shape, bend, and weld. It’s called cartridge brass because it’s often used to make ammunition shells.

This brass is great for hardware, plumbing, electrical parts, architectural work, and consumer products.

Pro

- Very ductile

- Resists corrosion well

- Easy to form and work with

Contro

- Doesn’t react well to acids like acetic, hydrochloric, or nitric

- Not good around ammonia or ammonia-based compounds

Ottone C360

C360 is the most popular brass for CNC machining. It’s also called free-cutting or free-machining brass because it has about 3% lead, which makes it really easy to machine.

You’ll find it great for parts like screws, valves, fittings, fasteners, and joints, especially if you need to solder or braze them. It also holds up well under pressure and doesn’t crack easily.

Pro:

- Resists corrosion well

- Elevata resistenza alla trazione

- Easy to shape and machine

Contro:

- Doesn’t hold up against acid

- The lead in it is not good for medical use

Surface Finishing Options for CNC-Machined Brass

Here are some of the common finishes you can choose for your machined brass parts:

Polishing: For a Shiny, Mirror-Like Look

Polishing is a great choice when you want your brass part to look really shiny, like a mirror. It’s perfect for parts that people will see, like musical instruments or decorative pieces. Aside from making your part look better, it also helps in protecting it from rust.

Brushing: For a Soft, Textured Look

Brushing gives your brass part a soft, even texture instead of a shiny look. It’s a good option when you want the part to look more subtle and less flashy. People often choose brushing for architectural designs where a clean, simple style is best.

Plating: For Stronger Protection and a New Look

Plating covers your brass part with another metal, like gold, silver, nickel, or chrome. It makes the part stronger and better at resisting rust and damage. Plating also changes how your part looks, depending on the metal you use.

Applications of CNC Brass Components

Many industries use CNC brass parts, such as the following:

Plumbing and Heating

You use brass to make parts like valves, fittings, and apparecchi because it resists rust and transfers heat well. Brass parts are strong and can handle tough conditions, so they are perfect for these jobs.

Automotive

In the automotive industry, you use brass for things like radiator cores, sensors, and electrical connectors. Brass is easy to machine and very durable, which is important when you need precise parts that last a long time.

Electrical and Electronics

You can choose brass for making electrical parts such as connectors, switches, and terminals. It conducts electricity well, is easy to machine, and resists corrosion. Plus, brass looks good, so it’s great for high-end electronics too.

Industria nautica

If you build parts for boats or anything used in the ocean, you choose brass. Saltwater, humidity, and temperature changes can damage other metals, but brass stays strong and resists corrosion, so it is ideal for propellers, fittings, and fasteners.

What are the Factors to Consider for Custom Brass Parts?

There are many things you need to keep in mind when machining custom brass parts, and these are the following:

Material properties: Make sure the type of brass you choose matches what your project needs.

Production volume: CNC machining works for small or large orders. Think about the costs and choose the best option for your budget.

Tolerances and dimensions: CNC machines can make very precise parts. Check that the machine can meet the exact sizes you need.

Design complexity: CNC machining is great for making detailed and complicated parts. But make sure your design is not too difficult to manufacture.

Lead time: Think about how fast you need the parts. Check things like material availability, tooling, and how busy the production schedule is.

Conclusione

If you’re looking to create high-quality brass parts, DEK is ready to help. Our expert team specializes in CNC machining services, including milling, turning, drilling, and EDM. With years of experience working with different brass alloys, we know exactly how to handle your project, no matter how simple or complex it is.

At DEK, we are ISO 9001 certified, which means you can count on us for consistent, reliable results. Plus, we guarantee fast communication; you’ll always hear back from us within 12 hours. Contattateci today to get started!

FAQs about CNC Machining Brass

What is the tolerance range for brass?

The typical tolerance range for CNC-machined brass parts is ±0.005 mm, depending on the design and machining process.

C'è qualche svantaggio nella lavorazione CNC dell'ottone?

Yes, some types of brass are not suitable for medical or food-related applications due to potential toxicity. Also, brass is softer compared to steel, so it may scratch or dent more easily in some environments.

What is the lead time for machining brass?

At DEK, the typical lead time for machining brass parts is around 4-7 days, depending on the complexity and volume of the order.