Aluminum Extrusion Machining Service

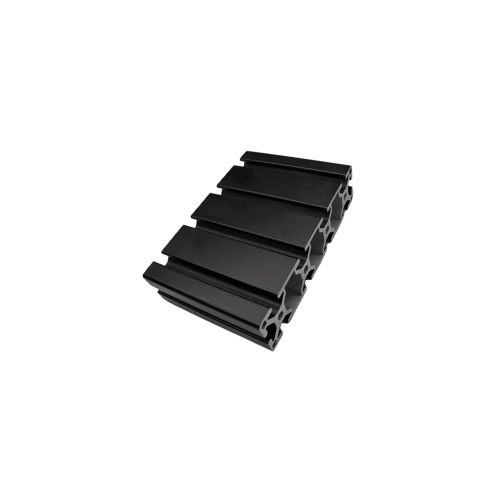

Turn your designs into strong, lightweight components with our aluminum extrusion machining services. We deliver custom profiles, smooth finishes, and precise cuts to match your specifications.

At DEK, every extrusion is engineered for accuracy with tight tolerances and consistent quality. We handle design review, cutting, machining, and finishing in one facility. Each part is inspected to meet performance requirements, supporting efficient assembly and reliability. From prototype to production, we deliver the precision and consistency your project needs.

introduzione

Aluminum Extrusion Machining | Precision, Strength, Custom Profiles

DEK delivers aluminum extrusion machining with accurate profiles, tight tolerances, and durable finishes, creating strong, lightweight components that meet strict performance requirements in aerospace, automotive, electronics, and more.

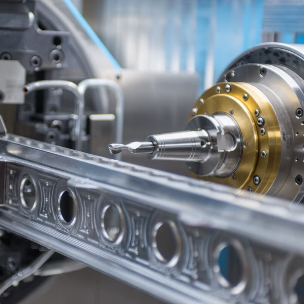

With DEK, aluminum extrusion machining is powered by advanced capabilities that ensure accuracy and consistency in every project. We use high-precision CNC machining centers, saws, and milling machines to process extrusions with exact dimensions and clean finishes. Our equipment handles drilling, tapping, slotting, contour milling, and complex cutouts with minimal deviation. CMM inspection systems are integrated into our process to verify tolerances, ensuring every component meets strict structural and functional requirements for its application.

Beyond machining, DEK delivers complete extrusion support, including custom die design feedback, extrusion production, surface finishing, and secondary assembly.

- High-speed processing

- Complex profile handling

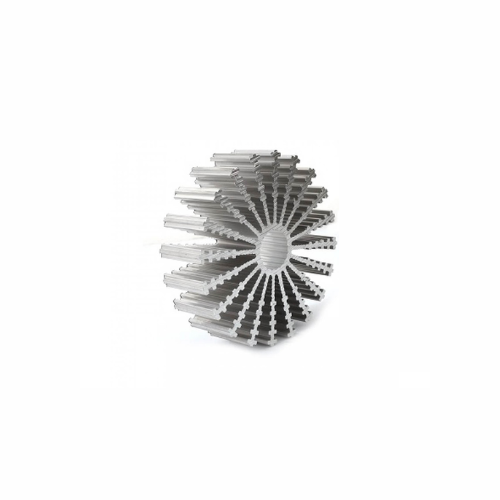

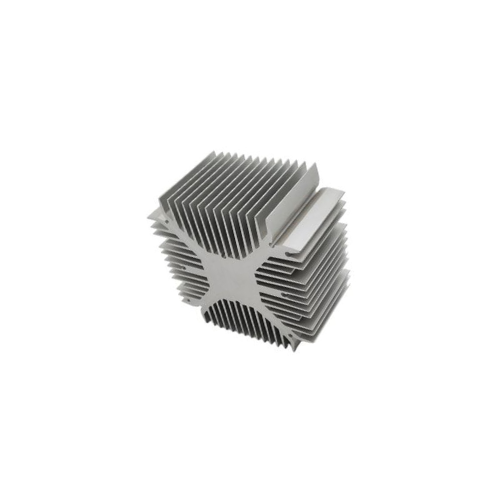

- Thermal management solutions

- Tight parallelism control

- Integration of threaded inserts

- Custom jigs and fixtures

I materiali for Aluminum Extrusion Machining

Leghe di alluminio

6061

At DEK, 6061 aluminum is one of the most versatile choices for aluminum extrusion machining. It offers an excellent balance of strength, corrosion resistance rating of 8/10, and machinability score of 90%, making it suitable for structural frames, machine components, and transportation parts.

Our process ensures tight tolerances and smooth finishes, allowing complex profiles to be integrated directly into assemblies. With its excellent anodizing response, 6061 extrusions can be tailored for both durability and appearance. Typical projects include precision machine frames, conveyor system rails, and custom heat sink housings for aerospace, automotive, electronics, and general engineering applications.

6063

DEK frequently uses 6063 aluminum alloy for extrusion machining when high-quality surface finish and corrosion resistance are priorities. Known as the “architectural alloy,” it features a tensile strength of 190 MPa, a corrosion resistance rating of 9/10, and a machinability score of 80%. ideal for window frames, door frames, enclosures, and decorative trims.

Our precision machining processes integrate slots, grooves, and mounting features directly into the extrusion, reducing secondary work. With excellent anodizing properties, 6063 supports aesthetic and functional coatings for outdoor and architectural use. Applications include architectural curtain wall frames, decorative panel trims, and precision instrument enclosures.

6082

In DEK’s aluminum extrusion machining, 6082 is the alloy of choice for demanding structural and load-bearing applications. Known for its high strength with tensile strength of 340 MPa and excellent machinability, it is well-suited to cranes, bridges, transport structures, and offshore platforms.

DEK’s machining capabilities create complex shapes and precision joints directly into extruded profiles, enhancing assembly efficiency. With strong corrosion resistance and weldability, 6082 is ideal for both indoor and outdoor applications such as heavy-duty support beams, transport vehicle chassis rails, and offshore walkway frames.

7075

DEK uses 7075 aluminum alloy in extrusion machining when maximum strength is required without sacrificing precision. This high-strength alloy offers excellent fatigue resistance, making it ideal for aerospace components, defense hardware, and high-performance sporting equipment.

Our advanced CNC processes machine detailed geometries into 7075 extrusions with minimal deviation, maintaining tight tolerances. Although less corrosion-resistant than some alloys, DEK applies protective surface treatments to extend service life. Common uses include aerospace landing gear struts, precision firearm receiver housings, and performance bicycle frame members.

2024

In DEK’s aluminum extrusion machining, 2024 is valued for its superior fatigue resistance and high strength, making it ideal for aerospace and motorsport applications. It performs exceptionally well in parts subjected to repeated stress, such as wing structures, fuselage components, and racing chassis elements.

Our extrusion and precision machining processes allow complex features to be integrated seamlessly. While 2024 has limited corrosion resistance, DEK applies coatings like anodizing or plating to ensure durability. It is often used for aircraft fuselage stiffeners, racing car suspension arms, and helicopter rotor hub components.

5052

DEK works with 5052 aluminum alloy for extrusion machining projects requiring excellent corrosion resistance with a rating of 9/10, especially in marine and coastal environments. Its superior formability and weldability make it a strong choice for boat components, fuel tanks, enclosures, and food processing equipment.

DEK’s machining process incorporates precise holes, slots, and cutouts into extruded profiles, ensuring components are ready for immediate assembly. Typical applications include marine deck railings, refrigerated truck body panels, and food-grade processing enclosures.

5083

DEK’s aluminum extrusion machining with 5083 alloy serves industries requiring extreme corrosion resistance with a rating of 10/10 and high strength with 317 MPa, such as marine, cryogenics, and defense sectors. Known for its performance in challenging environments, 5083 maintains structural integrity even under prolonged exposure to seawater or low temperatures.

Our machining process enables intricate detailing in extrusions while preserving mechanical properties. It is widely used in ship hull reinforcement beams, cryogenic storage vessel frames, and military vehicle armor panels.

Immediato e Citazioni precise

Non utilizziamo strumenti di quotazione automatizzati online, perché sono molto imprecisi. Le piattaforme di quotazione online si basano esclusivamente su calcoli basati su importi di taglio e coefficienti fissi, e non tengono conto delle reali sfumature di lavorazione, come la deformazione del materiale dopo il trattamento termico, gli stretti requisiti di tolleranza, la rettifica dopo il trattamento termico, ecc. Di conseguenza, i calcoli automatici dei prezzi possono portare a delle imprecisioni, aumentando i costi.

Ma da DEK potete stare tranquilli!

I nostri preventivi sono convenienti e accurati perché disponiamo di un team di ingegneri meccanici professionisti che esaminano meticolosamente ogni disegno. Questi ingegneri vantano oltre 10 anni di esperienza e possiedono una profonda competenza in materia di programmazione, funzionamento delle macchine, post-elaborazione, proprietà dei materiali e altro ancora. Vi assicuriamo preventivi accurati entro 6 ore.

I nostri vantaggi

Oltre 2300 ingegneri Amore Lavora con noi

Material Flexibility

DEK’s aluminum extrusion machining supports a wide range of alloys, including 6061, 6063, 6082, and specialty grades. We can work with extrusions in hard, soft, or delicate materials without compromising accuracy or surface quality.

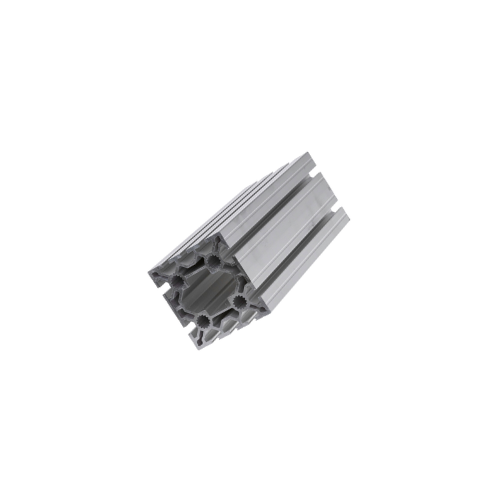

Complex Geometry

With advanced CNC machining, including 3-, 4-, and 5-axis capabilities, DEK processes intricate extrusion profiles with exceptional precision and tight tolerances. Our expertise allows integration of slots, grooves, angled cuts, deep pockets, and complex mating features directly into the extruded shape.

Efficienza dei costi

Our streamlined aluminum extrusion machining process minimizes setup time, material waste, and unnecessary secondary operations. By integrating extrusion and precision machining into a single, efficient workflow, we reduce production overhead and deliver cost savings directly to you.

Controllo qualità completo

We enforce rigorous quality control throughout every stage of aluminum extrusion machining, from initial material inspection to in-process measurements and final verification. Using CMMs, micrometers, and surface roughness testers, we confirm each part meets your exact specifications.

Finiture di superficie personalizzate

DEK provides a wide selection of finishing options for aluminum extrusions, including Type II and Type III anodizing, powder coating, sandblasting, and polishing. These treatments improve durability, corrosion resistance, and visual appeal while addressing precise functional needs.

Secure Global Shipping

Our packaging solutions include foam inserts, anti-rust wrapping, corrugated boxes, and custom wood crates. Each shipment includes a detailed packing list for accurate tracking and verification. We deliver worldwide using trusted couriers such as DHL, FedEx, and UPS, as well as sea or air freight for bulk orders.

Il nostro Processo di ordinazione

Invia RFQ

Inviare RFQ con disegni 2D/3D e requisiti dettagliati tramite e-mail o modulo online.

Recensione e preventivo

Il nostro team di ingegneri esaminerà attentamente ogni disegno e fornirà un preventivo accurato entro 6 ore.

Confermare l'ordine

Confermate il preventivo, i dettagli e il programma di consegna, quindi firmate il contratto.

Produzione

Organizzare il processo di produzione, avviare la programmazione e la lavorazione.

Controllo qualità

Rigoroso controllo di qualità durante la produzione e l'ispezione finale.

Imballaggio e spedizione

Imballare i pezzi, applicare le etichette di identificazione e iniziare la spedizione.

Inviare RFQ 222

Recensione e preventivo

Confermare l'ordine

Produzione

QC

Consegna

FAQ

Aluminum Extrusion Machining Domande frequenti sull'acquisto

Ottenere un preventivo accurato Per i vostri prossimi progetti

Non importa se il vostro progetto è complicato o semplice, se è in metallo o in plastica, riceverete un preventivo accurato entro 6 ore.

Richiedete un preventivo oggi stessoConoscere Aluminum Extrusion Machining

What is Aluminum Extrusion Machining?

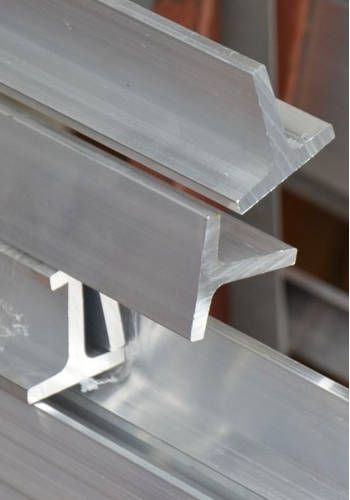

Aluminum extrusion machining is the process of creating custom aluminum profiles by pushing heated aluminum through a shaped die, then precisely cutting and machining the extruded pieces. This combination allows you to produce strong, lightweight components with complex cross-sections. Machining operations—such as drilling, tapping, milling, and finishing—are added after extrusion to meet exact specifications, improving function, fit, and appearance.

It is a versatile manufacturing method that supports both prototyping and large-scale production. With the ability to work in a wide range of alloys, it can meet specific requirements for strength, corrosion resistance, and thermal performance in industries from aerospace to consumer products.

What are the Advantages of Aluminum Extrusion Machining?

Aluminum extrusion machining combines the flexibility of extrusion with the precision of CNC machining, offering:

- Complex shapes with consistent cross-sections

- High strength-to-weight ratio in parts

- Reduced material waste and cost efficiency

- Excellent corrosion resistance with suitable alloys

- Smooth finishes with optional anodizing or coating

- Ability to integrate multiple features in one profile

- Shorter production times than full machining

- Reliable, high-quality components

When Do You Need Aluminum Extrusion Machining?

You need aluminum extrusion machining when your design requires long, uniform profiles with detailed machining features. It’s ideal for frames, enclosures, heat sinks, rails, and structural components across industries like aerospace, automotive, electronics, and construction. This method is especially useful when you want to balance lightweight design, structural strength, and precise functionality, without excessive machining time or cost.

It is also a practical choice when projects demand consistent part-to-part accuracy across high volumes. By combining extrusion with precision machining, you can streamline assembly, reduce secondary operations, and achieve repeatable quality even in complex designs.