CNC lathe parts play an important role in securing the accuracy and efficiency of lathe machines. Understanding the important components and parts of these machines is necessary for technicians and creators looking to maximize productivity and machine lifetime.

In this blog, you can learn about the important CNC lathe parts, their functions, support guidelines, and how to maintain their performance for long-lasting stability.

What is A CNC Lathe Machine?

A CNC lathe machine is a computer-controlled device that revolves a part against a cutting tool to perform multiple activities, such as turning, preparing, and cutting threads. It uses accurate instructions from a CNC system, authorizing manufacturers to manufacture parts with high accuracy. CNC lathes are commonly used throughout industries such as aerospace, automotive, and manufacturing.

The CNC system guarantees that the machine works smoothly without physical involvement, improving speed, accuracy, and reliability for even the most advanced tasks.

How Does a CNC Lathe Machine Work?

In a CNC lathe, the workpiece is secured in place by a chuck or collet while the cutting tool is relocated along several axes. Typically, X, Z, and sometimes Y are used based on the difficulty of the operation. The movement of both the workpiece and tool is controlled by CNC software that offers highly accurate, consistent results.

CNC lathes are known for their capability to build complex shapes and maintain secure tolerances. The CNC system can control various operations together, such as threading, boring, and cutting, improving efficiency in one installation.

Main CNC Lathe Parts

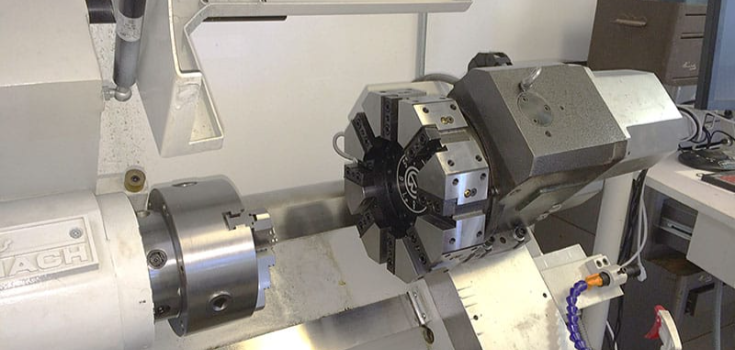

Testata

The headstock is one of the most important CNC lathe parts as it manages the rotation of the object. It contains the spindle and holds up the motor. The headstock secures smoothness and accurate spinning, which is necessary for getting accurate tolerances and quality finishes.

The headstock also contains the chuck, which grips the object in place. Its construction and resistance directly impact the machining accuracy and the capability to handle superior cutting pressure.

CNC Lathe Bed

The lathe bed offers the architectural support for the machine and is necessary for reliability. It receives machining forces and secures alignment, avoiding displacement during machining. An inflexible, high-quality foundation plays a significant role in durable accuracy and reliability.

A high-quality lathe foundation is necessary for extended processing, as it reduces heat expansion and changes that can cause errors in machining.

Chuck

The chuck controls the object safely in place during machining. It can be a three-jaw or four-jaw chuck, depending on the type of work being completed. A well-maintained chuck assures accurate gripping and avoids workpiece slipping, which is necessary for accuracy.

Chuck type selection relies on the shape of the workpiece. Three-jaw chucks are useful for round pieces, while four-jaw chucks provide good control for different-shaped objects.

Contropunta

The tailstock is placed opposite the headstock. The tailstock delivers strength for long or thin objects. It assures reliability and stops bending during lavorazione. It is widely used in operations like drilling and reaming.

By placing the tailstock properly, you can get a perfect alignment of lengthy spindles, useful to prevent bending or reduce errors at the time of machining.

Tailstock Quill

The tailstock quill expands and retracts to provide central support. It can be modified for arrangement with the spindle and is used to grip tools for perforazione or tapping operations. Proper adjustment of the tailstock quill assures high-accuracy results.

This part is essential when machining long parts. It supports the free end of the workpiece or displacement during rotation.

Foot Switch or Foot Pedals

Foot switches or pedals are utilized to handle certain machine functions without the need to use hands, advancing technicians’ productivity. They authorize quick and safe operation during recurring tasks like machine start/stop or instrument changes.

Foot pedals are particularly helpful when the technician requires both hands free to manage workpieces or instruments, securing smoother tasks in high-speed environments.

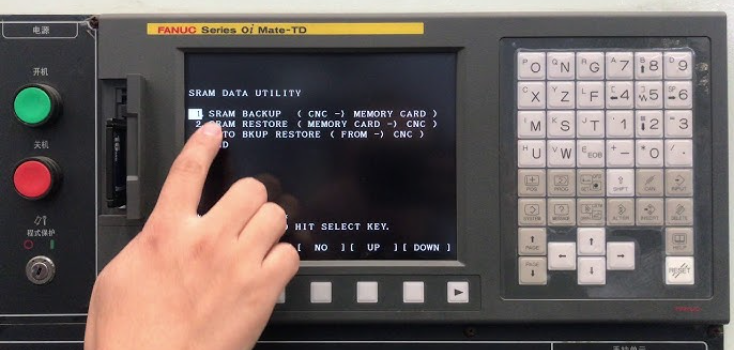

CNC Control Panel

The CNC control panel serves as the command center for the machine. Its operations are input from the technicians, control the spindle speed, feed rate, and instrument changes, and ensure the effortless operation of the lathe. The interaction can extend from simple to advanced. It provides more advanced functions like real-time diagnostics and automation.

Advanced control panels also feature touch-screen connections for user-friendly and authorization for the integration of Industry 4.0 abilities like data analytics and projection-based maintenance.

Tool Turret

The tool turret grips and rotates different cutting instruments on the CNC lathe. It allows for automatic instrument changes. Tool Turret allows streamlined multi-operation processes without manual involvement. A well-functioning turret guarantees accuracy and decreases downtime.

The tool turret supports quick setup and high accuracy, which is especially important for complicated machining tasks that need several tools in one cycle.

How to Maintain CNC Lathe Machine Parts Well?

Routine Inspection

Regular inspections are crucial to detecting wear and tear before it becomes a problem. Check the surface, headstock, tailstock, and other parts for any indications of damage or displacement.

Routine inspection can help you avoid major failures and support you in managing small issues before they disturb production.

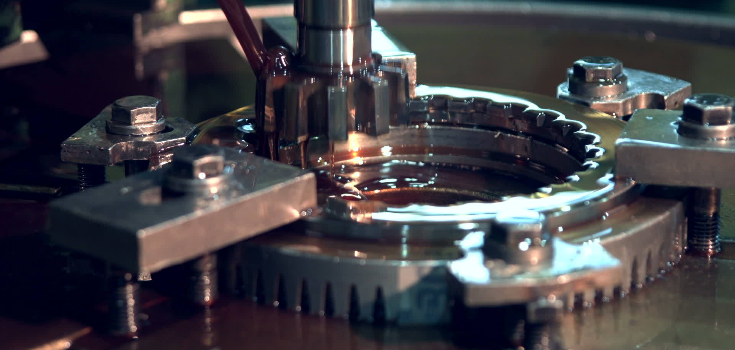

Lubrificazione

Proper lubrication of moving parts, such as the support, tool turret, and bearings, helps decrease friction and wear. It increases the life of elements and makes operations easier.

Lubricants should be appointed based on the machine's parameters, and regular checks should be performed to confirm that they are free of contaminants.

Cleanliness

Keep the machine clean. Dust and contaminants can affect the accuracy of CNC lathe parts and trigger issues like increased wear or impurity in the lubrication system.

A clean working environment decreases the risk of dust collection and ensures the valid operation of machine parts.

Update Software

Regular software updates ensure that your CNC lathe’s control system operations are consistent and stay compatible with the modern features and improvements.

Software updates can include improved performance, error diagnosis, and new machining abilities that improve the general performance of your machine.

Calibration

Calibration confirms that the machine maintains accuracy over time. Regularly check the adjustment and positioning of parts, such as the tailstock and chuck, to confirm they are within tolerance.

This step is important for maintaining secure tolerances, specifically for essential operations like threading or facing.

Train Operators

Well-trained operators can identify issues early and operate the machine more perfectly. Proper training is critical for avoiding mistakes and decreasing unnecessary wear on the machine.

A trained controller can also adapt to new technologies, like modern CNC control systems, to streamline machine performance.

Check Electrical Components

Electrical issues can lead to machine breakdowns. Regularly check wiring, connectors, and motors to avoid failures in operation.

Electrical maintenance includes checking for loose, unstable connections, overheating, and all of which can modify machine performance.

Backup Data

Ensure that all data, involving program files and machine settings, is verified frequently to prevent loss in case of a system failure.

Data backup is critical for preventing suspension and confirming the consistency of operations in the event of a sudden failure.

Follow Manufacturer's Guidelines

Always conform to the maintenance schedule given by the manufacturer. It will give specific instructions for your machine model, confirming optimal performance.

The manufacturer’s guidelines also include suggested replacement gaps for fundamental components like bearings and spindles.

Conclusione

Understanding the essential CNC lathe parts and how they contribute to overall performance is essential for technicians. Proper and regular upgradation can extend the life of machines and retain their validity.

For expert CNC machining solutions, DEK provides top-quality lathe machine parts, modified for your operational needs. Reach out to us today and optimize your CNC lathe performance!