Servicio de moldeo por inyección

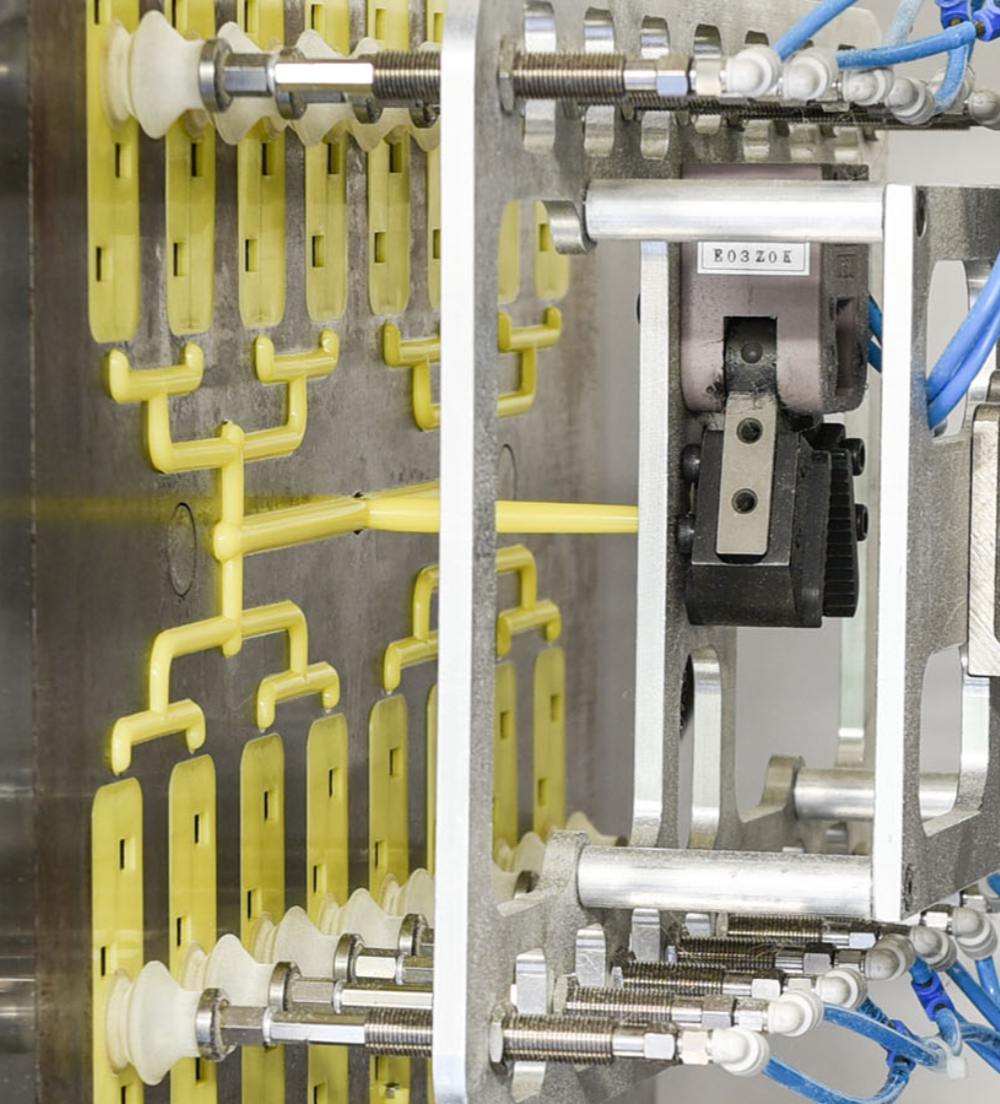

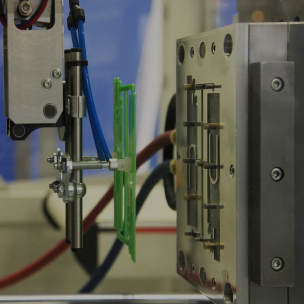

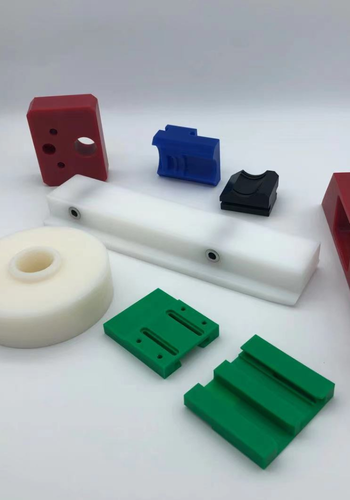

Estamos especializados en herramientas personalizadas, fabricación de moldes y moldeo por inyección de volúmenes medios y altos. También ofrecemos operaciones secundarias, acabado de superficies y servicios de montaje.

DEK offers precise, cost-effective molded components to clients across several industries. Using specialized molds, our manufacturing technique can produce consistent plastic components. We focus on producing accurate, high-quality molded parts that meet your specific needs. Whether you require a prototype or hundreds to thousands of components, our reliable and swift molding service is up to the task. Our manufacturing process follows a tight precision level of +/-0.005mm, ensuring you get consistent parts all around.

introducción

Moldeo por inyección | Consistent, High Precision, Cost-Effective

DEK offers high-quality, consistent, and precise molded components that are cost-effective. Whether you’re ordering in small or large quantities, we offer you relatively fair pricing.

With our specialized molds, team of experts, technological machines and tools, and variety of materials, we give reliable, effective, and efficient injection molding service. We are also ISO 9001, ISO 13485, and AS9100D certified, so you can be sure our manufacturing processes follow strict regulatory compliance.

You can order any amount, as we don’t have an MOQ. Whether you need just simple components or ones with complex geometries, we're here to serve.

- A wide variety of plastics to select from

- Tight tolerance within +/-0.005mm

- End-to-end quality assurance

- Custom finishes and surface treatments

- Professional packaging and worldwide delivery

Materials for Injection Molding

Plásticos

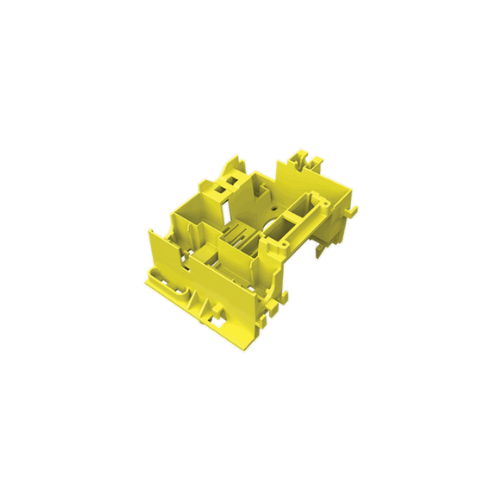

ABS

ABS is a tough, impact-resistant plastic known for its strength, rigidity, and ability to withstand everyday wear. It is easy to mold, has good surface finish qualities, and offers decent resistance to heat and chemicals.

At DEK, we use ABS to create durable and high-quality parts for the automotive, consumer electronics, and home appliance industries. These include components like dashboard panels, automotive sensor housing, device enclosures, etc. DEK’s injection molding service guarantees accuracy and reliability across every project, large or small.

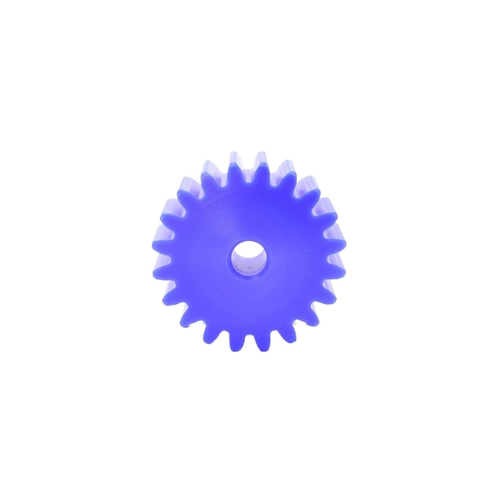

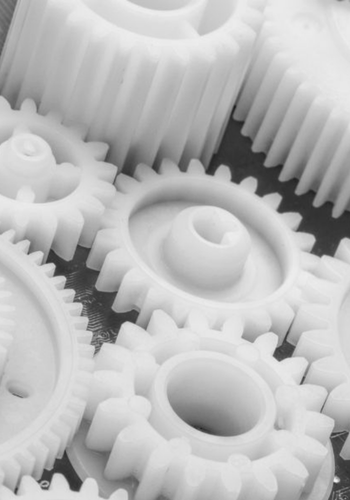

Nylon

Nylon is a strong, wear-resistant plastic with good thermal and chemical resistance. It performs well in mechanical applications requiring toughness, self-lubrication, and low friction under stress.

At DEK, we mold nylon into high-performance parts used in gears, bearings, and structural components across several industries. We focus on quality and detail; you’ll receive nylon components built to handle demanding conditions with accuracy and endurance that meet your industry’s expectations.

Grados

Nylon 6, Nylon 6 (30% Glass Filled), Nylon 6/6 (30% Glass Filled), Nylon 6 Flame Retardant.

PC

PC is a strong and transparent plastic with high impact resistance and excellent dimensional stability. It holds up well under pressure and heat, making it suitable for applications requiring clarity and toughness at the same time.

At DEK, we use PC to produce robust and clear parts for lighting, safety gear, and electronics. Our skilled technicians deliver precision-molded components with smooth finishes and accurate detailing. Whether it’s protective casings or lenses, you can count on DEK’s high standards in quality, strength, and clarity to meet your exact industrial requirements with confidence.

PE

PE is a lightweight plastic known for its flexibility, chemical resistance, and moisture tolerance. It can handle low temperatures and repetitive stress, making it popular for packaging and fluid-handling systems.

At DEK, we mold PE into durable, flexible components used in industries like food processing, plumbing, and packaging. Our advanced equipment and skilled team ensure that every part is produced to exact specifications. We focus on delivering smooth surfaces and long-lasting performance, helping you get reliable, cost-effective plastic parts with DEK’s trusted quality and accurate results.

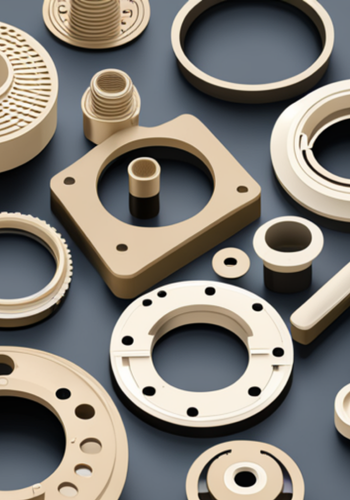

PEEK

PEEK is a high-performance plastic known for its exceptional heat resistance, mechanical strength, and chemical stability. It’s ideal for harsh environments and demanding engineering applications, especially where metal replacement is needed.

DEK uses PEEK to produce ultra-precise, durable parts for aerospace, medical, and electronics sectors. Our machines handle the material’s complexity while delivering excellent surface finish and accuracy. We make sure every part meets tight tolerances and performs reliably under stress. When your applications demand advanced materials and perfect execution, DEK’s expertise with PEEK gives you unmatched quality and precision.

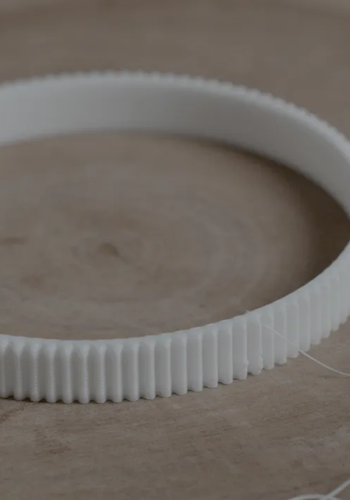

PP

PP is a lightweight, chemical-resistant plastic known for its fatigue resistance and flexibility. It is ideal for applications requiring hinged parts, containers, and medical components due to its durability and low moisture absorption.

At DEK, we use PP to create flexible and functional parts for the medical, packaging, and automotive sectors. Our molding process ensures high precision, consistent wall thickness, and smooth finishes.

Grados

PP Homopolímero, PP+GF(30%)

TPU

TPU is a flexible and elastic plastic with excellent abrasion resistance, impact strength, and resistance to oils and greases. It’s suitable for parts needing both strength and flexibility, like seals and protective covers.

With DEK’s injection molding service, we mold TPU into rugged, flexible components for industrial, automotive, and medical applications. These components include catheters, connector housing, automotive bushings, etc. We focus on tight tolerances, detailed features, and smooth finishes. We combine high-quality materials with expert craftsmanship so you receive durable, high-precision components designed for real-world performance and reliability.

Versátil Acabado de superficies Opciones

Anodizado

El anodizado es un proceso electroquímico que mejora la resistencia a la corrosión, la durabilidad y el aspecto de los metales, especialmente el aluminio.

Óxido negro

Get functional and aesthetic benefits in one with Black Oxide surface finishing. It's a matte […]

Revestimiento DLC

The low friction coefficient of DLC coatings reduces resistance between surfaces, providing durability to components […]

Al instante & Citas precisas

No utilizamos herramientas de presupuesto automatizadas en línea, porque son muy imprecisas. Las plataformas de presupuesto en línea se basan únicamente en cálculos basados en cantidades de corte y coeficientes fijos, y no tienen en cuenta los matices reales de procesamiento, como la deformación del material tras el tratamiento térmico, requisitos de tolerancia estrictos, rectificado tras el tratamiento térmico, etc. En consecuencia, los cálculos de precios automatizados pueden dar lugar a imprecisiones que, en última instancia, aumentan sus costes.

¡Pero puedes estar tranquilo en DEK!

Nuestros presupuestos son rentables y precisos porque contamos con un equipo de ingenieros mecánicos profesionales que revisan meticulosamente cada dibujo. Estos ingenieros cuentan con más de 10 años de experiencia y poseen profundos conocimientos en programación, funcionamiento de máquinas, posprocesamiento, propiedades de materiales y mucho más. Le garantizamos que obtendrá presupuestos precisos en menos de 6 horas.

Nuestras ventajas

Más de 2300 ingenieros Trabaja con nosotros

Alta precisión

We ensure every part is produced with tight tolerances and exact dimensions. At DEK, we focus on delivering consistent accuracy for even the most detailed components. Your parts will fit, function, and perform just as expected every single time.

Complex Geometry

Whether your part includes undercuts, thin walls, or internal channels, our molding process and tooling capabilities can handle it all. You can rely on us to turn even your most challenging designs into fully functional and perfectly molded components.

Calidad certificada

We follow internationally recognized standards and perform strict quality checks throughout the production process. You’ll receive parts that meet your industry’s performance and safety requirements, backed by ISO certifications and full inspection reports.

Acabado de superficies

Beyond molding, DEK offers a range of surface finishing treatments to enhance the appearance and performance of your parts. From smooth polish to textured finishes, we tailor the final look to match your application.

Rentabilidad

Our efficient production systems and material optimization reduce waste and labor, saving you money without compromising quality. At DEK, you receive top-tier injection molding services at competitive prices.

Versatilidad de materiales

DEK supports a wide range of plastics. This gives you the freedom to choose the right material for your application. Whatever your industry or performance requirement, we help you select and mold the ideal material to bring your part to life.

Nuestra Proceso de pedido

Enviar petición de oferta

Enviar RFQ con dibujos 2D/3D y requisitos detallados a través de correo electrónico o formulario en línea.

Revisión y presupuesto

Nuestro equipo de ingenieros revisará detenidamente cada plano y le proporcionará un presupuesto preciso en un plazo de 6 horas.

Confirmar pedido

Confirma el presupuesto, los detalles y el plazo de entrega, y luego firma el contrato.

Producción

Organizar el proceso de producción, iniciar la programación y el mecanizado.

Control de calidad

Estricto control de calidad durante la producción y la inspección final.

Embalaje y envío

Empaquete las piezas, coloque las etiquetas de identificación de las piezas y comience el envío.

Enviar RFQ 222

Revisión y presupuesto

Confirmar pedido

Producción

QC

Entrega

PREGUNTAS FRECUENTES

Moldeo por inyección Preguntas frecuentes

Obtenga un presupuesto exacto Para sus próximos proyectos

No importa que su proyecto sea complicado o sencillo, no importa que sea de metal o de plástico, obtendrá un presupuesto preciso en un plazo de 6 horas.

Pida presupuesto hoy mismoMoldeo por inyección Perspectivas

¿Qué es el moldeo por inyección?

Injection molding is a manufacturing process used to create parts by injecting molten plastic into a mold. The mold is typically made from metal and designed to form the desired shape of the final product.

Once the plastic cools and solidifies, the mold opens, and the part is ejected. The process is fast, repeatable, and highly efficient for making large volumes of identical products. You start by choosing a suitable plastic, then the mold is closed, filled, cooled, and the part is released. If you need consistent, durable, and well-finished plastic parts with tight tolerances, injection molding is often the best solution to meet your production goals.

If you’ve moved past prototyping and are ready to scale your production, injection molding is likely the next step.

What are the Advantages of Injection Molding?

Injection molding offers reliable and efficient production with consistent quality, especially when you're creating parts in large volumes. It combines speed, precision, and material variety to deliver durable plastic components with clean finishes.

- Fast production cycles

- Consistent high-quality part

- Cost-effective production method

- Supports complex geometries

- High material flexibility

- Generación mínima de residuos

When Do You Use Injection Molding?

En el sector de la automoción, se utiliza para fabricar elementos interiores como paneles de salpicadero y piezas exteriores como parachoques. La industria de la electrónica de consumo se beneficia del moldeo por inyección para producir carcasas de dispositivos y componentes electrónicos intrincados.

En el campo médico, el método se utiliza para fabricar componentes de dispositivos médicos y piezas de precisión para equipos de diagnóstico. Las aplicaciones de envasado implican la creación de envases de plástico, tapones e insertos de envasado.

Its usage extends to appliances, construction materials, sporting goods, and household items, manufacturing diverse products with complex designs, precision, and consistency in large volumes.