If you’re working with titanium or considering it for a project, you need to understand its properties.

You need to know the melting point of titanium and what can affect it for using it effectively in different applications.

This guide will explain everything you need– let’s start!

Che cos'è il titanio?

Titanio is a versatile material due to its properties. It is a high-performance silver-gray lightweight metal. It is as strong as steel but significantly lighter, which makes it ideal if weight matters in your project.

It resists oxidation and corrosion in different environments like seawater and acidic conditions. It’s non-toxic and does not react with the human body. This means you can use it for medical implants.

It retains its strength and stability at elevated temperatures. These are the reasons why you can use titanium for aircraft, spacecraft, and missiles.

Titanium has different forms, such as pure titanium and titanium alloys. These forms differ in properties such as strength, ductility, and resistance to extreme conditions. You can choose the form based on your needs.

What is the Melting Point of Titanium?

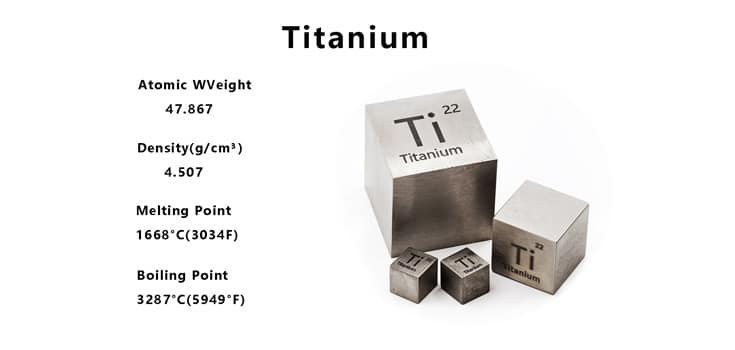

Titanium melting point is the temperature at which it can turn from solid to liquid state. The melt temperature of titanium is 1668°C (3,034°F).

Knowing this temperature is important, especially when you need to use it in processes like welding or casting, where the material’s behavior at high temperatures matters.

Its high melting point makes it an excellent choice for applications involving high-temperature environments, such as jet engines, turbines, and heat exchangers.

Factors Affecting Titanium’s Melting Point

The melting point of pure titanium is fixed. Several factors can influence how it behaves at high temperatures. Here are some of the factors you need to consider:

Purity of Titanium

If the titanium is not pure, its melting point may change. Impurities can slightly lower or raise titanium melting point, depending on their nature and concentration.

Elementi di lega

You can mix titanium with other metals to produce an alloy. Doing this can affect its melting point and other properties. Some metals that you can mix with titanium are aluminum and vanadium.

Aluminum adds strength and heat resistance, while vanadium improves flexibility and durability. These elements often create a melting point range rather than a single temperature.

Microstructure and Phase Composition

Titanium can exist in two main phases: alpha and beta phase. The proportion of these phases, influenced by alloy composition and heat treatment, can affect melting characteristics.

The alpha phase is stable at lower temperatures, offering good strength and corrosion resistance. The beta phase is stable at higher temperatures, providing greater flexibility.

The microstructure of titanium can also affect its properties and behavior under different conditions. Titanium with lamellar or layered microstructure offers better flexibility at low temperatures compared to evenly shaped grains.

Cryogenic titanium alloys are specially made for extremely low-temperature environments. They are typically near-α alloys or two-phase alloys with a small amount of β-phase, which improves performance.

Pressure Conditions

The melting temperature of titanium can vary under extreme pressure. High pressure tends to make the melting point higher, while lower pressure may slightly reduce it.

Vacuum or inert atmosphere maintains titanium’s standard melting point.

External Environmental

Titanium reacts with elements like oxygen and nitrogen at high temperatures. Oxygen or nitrogen exposure forms brittle layers on the surface, which can affect how the metal behaves when heated.

You can use a vacuum or inert gas during heating to prevent contamination and help maintain titanium’s properties.

Why Does Titanium Have Such a High Melting Point?

Titanium’s high melting point comes from its unique structure and chemical properties. Here are the main reasons you need to know:

Strong Atomic Bonds: Titanium atoms are tightly bonded, requiring a lot of energy to break apart.

High Electron Density: Its high electron density strengthens metallic bonds, making it harder to melt.

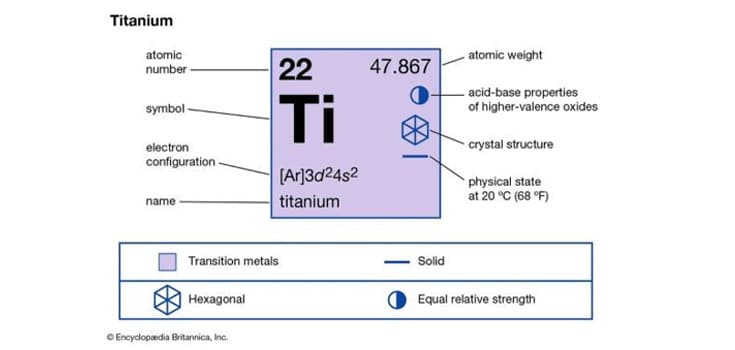

Compact Crystal Structure: The hexagonal close-packed (HCP) alpha phase of titanium is highly stable, even at high temperatures.

High Thermal Stability: Titanium resists changes in structure when exposed to heat, making it more temperature-resistant.

Resistance to Oxidation: Titanium forms a thin oxide layer that protects it from reacting with oxygen, even at elevated temperatures.

Titanium Alloys and Their Melting Points

Check the table below to know some examples of titanium alloys and their melting points:

| Example of Titanium Alloy | Punto di fusione (°C) |

| Ti 6AL-4V | 1878 – 1933 |

| Ti 6AL ELI | 1604 – 1660 |

| Ti 3Al 2.5 | ≤ 1700 |

| Ti 5Al-2.5S | ≤ 1590 |

Applications of Titanium Based on Its Melting Point

Titanium’s high melting point makes it perfect for demanding applications, including the following:

Aerospaziale

You’ll find titanium in jet engines, airframes, and spacecraft, where parts face extreme heat and stress. Titanium is an excellent material for aerospace prototyping, with unrivaled mechanical properties.

Medico

It is ideal for surgical implants and tools, as it remains stable in body temperatures and is biocompatible. Titanium is an indispensable material for the medical industry and one of the metals of choice for medical device prototyping.

Automotive

You can use it in performance vehicles for parts like exhaust systems and engine components that must handle high heat. Titanium's light weight, corrosion and heat resistance will play an increasingly important role in future automobilistico technology.

Generazione di energia

You can also find titanium in turbines and heat exchangers, where materials must endure high temperatures and pressures.

Difesa

For the defense industry, titanium is used for armor, naval ships, and missile systems due to its heat resistance and strength.

Challenges in Working with Titanium

While titanium is incredibly useful, there are still challenges when using it for manufacturing. Here are a few you might encounter:

Costo elevato

Titanium is expensive to extract, process, and machine, making it costlier than many other metals.

Difficult to Machine

Titanium’s strength and heat resistance make it tough to cut or shape, so you’ll need specialized tools or machine. Titanium parts are commonly machined in 5 assi.

Reactivity at High Temperatures

When heated, titanium reacts with oxygen and nitrogen, which can weaken its surface. You’ll need to work in a vacuum or inert atmosphere to avoid this.

Bassa conducibilità termica

Titanium doesn’t dissipate heat well, so it can overheat during machining or welding, potentially causing damage.

How Hard is it to Melt Titanium?

Melting titanium is challenging because it requires high temperatures. The strong atomic bonds in titanium need a lot of energy to break, so you’ll need specialized furnaces.

Titanium also reacts with oxygen and nitrogen, forming brittle compounds, so you must melt it in a vacuum or inert atmosphere.

Additionally, using the right equipment is crucial to handle the extreme heat and prevent reactivity. In short, melting titanium isn’t just about high temperatures; it requires careful control.

Titanium Melting Point vs. Other Metals

When choosing materials for high-temperature projects, understanding how titanium compares to other metals can help you make the best decision.

Here’s a quick breakdown:

Titanium vs. Steel

Titanium melting point is higher than steel’s melting point of 1,370–1,510°C (2,498–2,750°F).

This makes titanium better for high-temperature environments. However, steel is stronger and cheaper, making it more common for general use.

Titanium vs. Aluminum

Titanium’s melting point is much higher than aluminum’s 660°C (1,220°F).

Titanium is better for heat-resistant applications, but aluminum is lighter, cheaper, and easier to work with, making it ideal for less demanding uses.

Titanium vs. Copper

Copper melts at a lower temperature of 1,085°C (1,985°F). Copper is great for conducting heat and electricity, but it doesn’t handle high temperatures, as well as titanium, which is stronger and more resistant to corrosion.

Titanium vs. Nickel-Based Alloys

Nickel-based alloys like Inconel melt at 1,350–1,450°C (2,462–2,642°F), which is lower than titanium’s.

While these alloys are heat-resistant, titanium’s higher melting point and lighter weight make it a better choice for some high-temperature applications.

Summary of Comparison

| Metallo | Punto di fusione (°C) | Strengths | Weaknesses |

| Titanio | 1668 | Heat-resistant, lightweight | Expensive, hard to machine |

| Acciaio | 1370-1510 | Strong, affordable | Lower heat resistance |

| Alluminio | 660 | Lightweight, easy to work with | Poor heat resistance |

| Rame | 1085 | Good conductor of electricity | Not heat resistant enough |

| Nickel-based alloys | 1350-1450 | Resistenza alle alte temperature | Heavy, more expensive |

Conclusione

The melting temperature of titanium is ideal for high-temperature uses. While other metals have their advantages, titanium is the best choice for heat resistance, strength, and lightweight properties.

However, there are still other factors that you need to consider when making your choice, so contattare DEK now. Let us help you determine the right material for your application.