- Casa

- Costruzione

High Quality Custom Construction Parts Manufacturing

DEK specializes in the precision manufacturing of machined parts for the Construction industry. We offer high-quality, durable components to customers worldwide with industry-leading speed and at cost-effective prices. We can rapidly machine complex parts with tight tolerances of +/- 0.005mm, utilizing a wide range of production-grade materials and surface finish options. Get an instant quote!

- Competitive Price & Reliable

- 24/7 Engineering Support & DFM

- ISO 9001:2015 Certified.

- Rapido giro, breve tempo di consegna, non MOQ

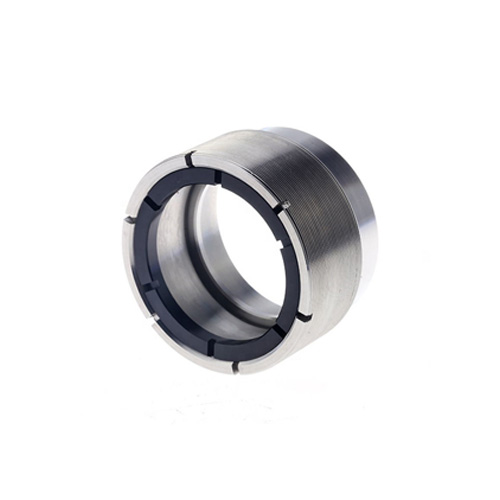

Precision Parts Manufacturing in the Construction Industry

DEK is your trusted partner for precision-machined custom parts for the construction industry, known for exceptional quality and service. Our parts are built to perform reliably in high-vibration and extreme weather environments.

As an ISO 9001 certified manufacturer, DEK offers advanced machining capabilities with tolerances up to ±0.005mm. We strictly adhere to construction industry standards, specializing in machining corrosion-resistant, high-strength materials such as stainless steel, alloy steel (e.g., 4140, 4340), ensuring every part delivers superior performance and exceptional durability.

Additionally, we offer surface treatments including passivation, electroplating, PVD coating, and QPQ coating. Our typical applications include architectural hardware, steel structure connectors, aluminum profiles, custom bolts, and nuts. We provide CMM inspection reports, FAI reports, and material certificates. Contact us now to quickly obtain your quote.

Machined Part

Machined Part

Staffa

Staffa

Turned Part

Turned Part

Machined Part

Turned Part

Construction Component Capacità di produzione

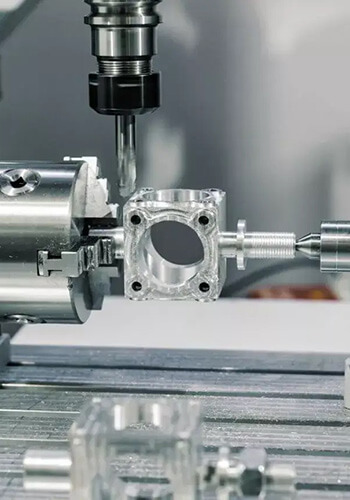

Lavorazione CNC di precisione

DEK offers fast, accurate, and reliable CNC precision machining services with tight tolerances up to ±0.005mm, ideal for manufacturing steel structural connectors, custom anchor bolts, precision shims & spacers, and brackets.

We specialize in 5-axis machining for complex, high-precision construction components. We provide rapid prototyping services and free DFM analysis to reduce costs. Whether you need a functional prototype or a reliable partner for small-batch production, DEK delivers flexible and efficient solutions.

Lavorazione della lamiera

DEK specializes in machining high-quality custom sheet metal parts for the construction industry. From metal frames to equipment enclosures, we provide reliable structural support and protection for your core components.

We offer a variety of sheet metal materials, including aluminum, stainless steel, and steel. From instant quotes to rapid production, you can receive hundreds of high-quality sheet metal parts in just a few days. Additionally, we provide surface treatment options, including brushing, anodizing, and coating, to meet your parts’ demanding requirements.

Stampa 3D industriale

DEK offers advanced additive manufacturing technologies, including metal 3D printing, SLA, SLS, and FDM, enabling low-cost rapid prototyping and the production of durable, corrosion-resistant parts with complex geometries.

We provide a wide range of metals and plastics, including stainless steel, alloy steel, PEEK, and PTFE, for printing special-shaped steel structure joints, corrosion-resistant pipe flanges, and high-stress building anchor bolts. Additionally, we offer surface treatments tailored to your project’s needs.

I materiali

I materiali Opzioni

Acciaio inox

This high-performance metal, renowned for its exceptional corrosion resistance, high strength, and fire-resistant properties, is the preferred material for architectural structural components, functional parts, and aesthetic or decorative applications.

Acciaio al carbonio

Carbon steel offers excellent machinability, weldability, and mechanical properties, making it widely used in the construction industry. It is ideal for manufacturing building frames, custom bolts, and rivets. Additionally, we provide DLC and PVD coating options.

Acciaio legato

Alloy steel is a high-strength, high-temperature resistant, and wear-resistant metal. It is the preferred material for drill pipes, flanges, tubing heads, high-pressure fasteners, and connectors, and it has excellent low-temperature impact toughness and good machinability.

Alluminio

Aluminum is lightweight, corrosion-resistant, easy to process, and aesthetically pleasing, making it ideal for large-span structures and high-rise buildings by reducing foundation loads. It is perfect for manufacturing curtain wall profiles, structural components, connectors, and aluminum composite panels.

Immediato e Citazioni precise

Non utilizziamo strumenti di quotazione automatizzati online, perché sono molto imprecisi. Le piattaforme di quotazione online si basano esclusivamente su calcoli basati su importi di taglio e coefficienti fissi, e non tengono conto delle reali sfumature di lavorazione, come la deformazione del materiale dopo il trattamento termico, gli stretti requisiti di tolleranza, la rettifica dopo il trattamento termico, ecc. Di conseguenza, i calcoli automatici dei prezzi possono portare a delle imprecisioni, aumentando i costi.

Ma da DEK potete stare tranquilli!

I nostri preventivi sono convenienti e accurati perché disponiamo di un team di ingegneri meccanici professionisti che esaminano meticolosamente ogni disegno. Questi ingegneri vantano oltre 10 anni di esperienza e possiedono una profonda competenza in materia di programmazione, funzionamento delle macchine, post-elaborazione, proprietà dei materiali e altro ancora. Vi assicuriamo preventivi accurati entro 6 ore.

Perché scegliere I nostri servizi

La produzione in un'unica soluzione di pezzi di alta qualità consente di risparmiare tempo e denaro.

Capacità ingegneristiche

Tempi di consegna rapidi

Controllo qualità

Finiture di superficie

Assemblaggio di precisione

Packaging and Logistics

Il nostro Processo di ordinazione

Invia RFQ

Inviare RFQ con disegni 2D/3D e requisiti dettagliati tramite e-mail o modulo online.

Recensione e preventivo

Il nostro team di ingegneri esaminerà attentamente ogni disegno e fornirà un preventivo accurato entro 6 ore.

Confermare l'ordine

Confermate il preventivo, i dettagli e il programma di consegna, quindi firmate il contratto.

Produzione

Organizzare il processo di produzione, avviare la programmazione e la lavorazione.

Controllo qualità

Rigoroso controllo di qualità durante la produzione e l'ispezione finale.

Imballaggio e spedizione

Imballare i pezzi, applicare le etichette di identificazione e iniziare la spedizione.