Aerospace Sheet Metal Fabrication Service

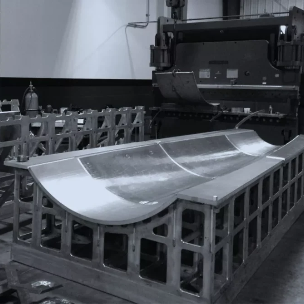

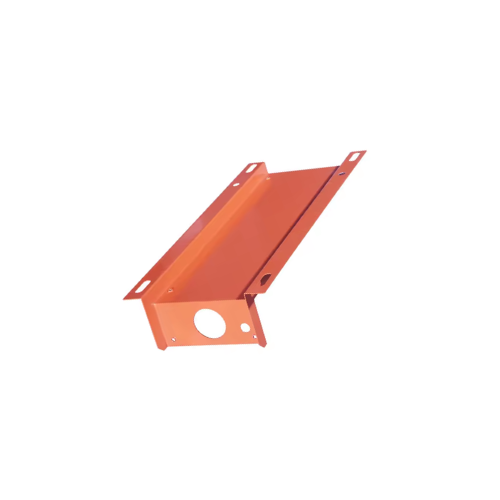

Aerospace sheet metal fabrication uses cutting, bending, and forming to make precise, lightweight parts that need tight tolerances and flight standards for strength and safety.

DEK offers custom sheet metal fabrication for all types of aircraft. We make complex parts for commercial, military, and private aircraft. From titanium skins to aluminum supports, we handle demanding jobs with speed and accuracy. Every part is inspected to meet strict aerospace requirements and built to handle pressure, heat, and motion.

introducción

Aerospace Sheet Metal Fabrication | Built to Spec, Built to Last

DEK makes aerospace sheet metal parts to your exact specs. We use fast service, advanced machines, and certified materials to support your toughest builds.

We provide full-service aerospace sheet metal fabrication designed for strength, accuracy, and repeatability. Every part is built to spec and made to last under real flight conditions. We use advanced tools like laser cutters, CNC punch presses, press brakes, and welding systems to shape certified materials—aluminum, titanium, stainless steel, and aerospace-grade alloys. From skins and brackets to enclosures and frames, your parts are cut, formed, and assembled with care. We also offer DFM support, rapid prototyping, surface finishing, and final assembly—all under one roof. In-process inspections and CMM checks ensure every part performs under pressure, heat, and motion.

Whether you need one part or full production, DEK delivers fast turnaround, consistent quality, and responsive support from start to finish.

- In-process inspections

- Flight-ready quality

- Custom tooling and jigs

- One-stop service

- Full DFM support

- Creación rápida de prototipos

Materiales for Aerospace Sheet Metal Fabrication

Metales

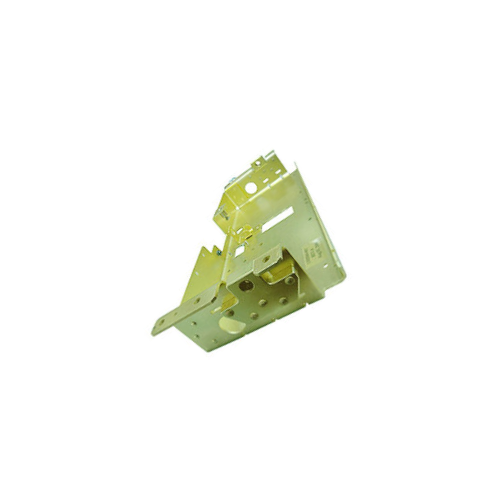

Acero aleado

Alloy steel offers exceptional strength, toughness, and weldability, making it perfect for aerospace sheet metal fabrication of structural supports, tubing, and mechanical assemblies.

DEK fabricates precision parts like struts, hydraulic line brackets, and reinforcement ribs with exacting quality and tight tolerances. Our experienced team uses advanced forming, welding, and finishing processes to ensure these components meet stringent aerospace requirements for durability and resilience. You get reliable, high-performance parts designed to withstand heavy loads and demanding operating conditions.

Aleaciones

4140, 4340, AISI 4130, 8620

Aluminio

Aluminum offers exceptional lightness and natural corrosion resistance, making it a top choice in aerospace sheet metal fabrication for skins, fuselage panels, and structural frames. Its excellent formability allows precise bending and shaping to tight tolerances.

DEK’s advanced fabrication techniques ensure smooth finishes and consistent quality for parts like wing skins, bulkheads, and cargo floor panels. Whether for prototypes or production runs, we deliver components that meet strict aerospace strength and weight standards, helping you build efficient and reliable aircraft.

Aleaciones

2024, 6061, 7075, 5052

Inconel

Inconel’s exceptional heat and corrosion resistance make it key for aerospace sheet metal fabrication in engine components, heat shields, and turbine blades.

DEK precisely fabricates parts such as exhaust manifolds, combustion chamber liners, and nozzle guide vanes. Our skilled processes maintain Inconel’s integrity under extreme temperatures and stress. The components we produce support engine reliability, durability, and performance, enabling aerospace systems to operate safely and efficiently in the harshest environments.

Aleaciones

Inconel 718, Inconel 625, Inconel 600

Magnesio

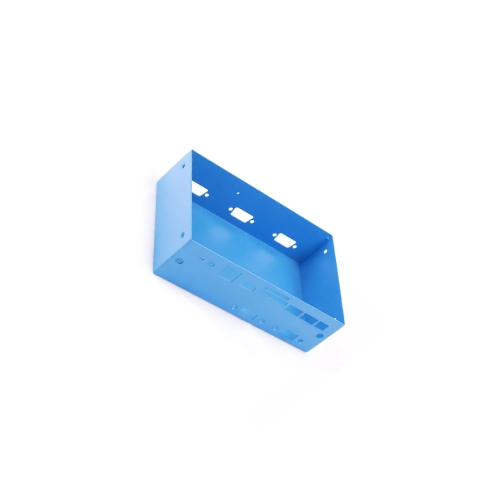

Magnesium’s lightweight properties suit aerospace sheet metal fabrication for parts where weight reduction is critical, including instrument housings, interior panels, and seat frames.

DEK handles magnesium carefully to produce components like avionics enclosures, cockpit panels, and structural brackets. Our fabrication processes ensure these parts meet aerospace standards for strength and dimensional accuracy while contributing to overall aircraft weight savings. Magnesium’s use helps improve fuel efficiency and performance by reducing aircraft mass without sacrificing durability.

Aleaciones

AZ31B, AZ61A, etc.

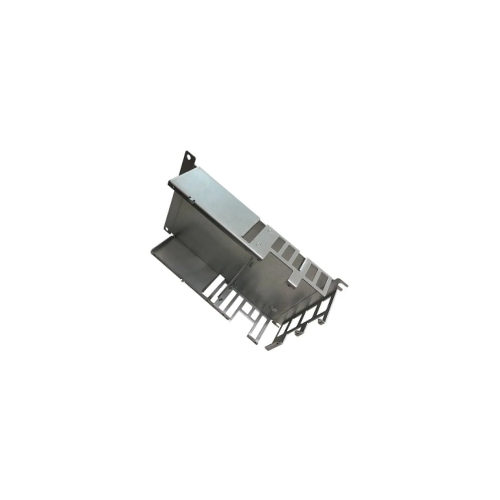

Acero inoxidable

Stainless steel is a reliable choice in aerospace sheet metal fabrication for parts requiring strength and corrosion resistance, such as exhaust ducts, fasteners, and mounting brackets.

DEK ensures precise forming and finishing to meet aerospace specifications. Our expertise supports manufacturing heat shields, fuel line supports, and bracket assemblies that withstand harsh environments, temperature changes, and mechanical stress. We provide durable, long-lasting components essential for aircraft safety, structural integrity, and operational reliability.

Aleaciones

304, 316, 321, 17-4 PH

Acero para herramientas

Tool steel is essential in aerospace sheet metal fabrication for tooling, dies, and precision fixtures.

DEK creates components like press dies, forming tools, and precision jigs that maintain hardness, wear resistance, and dimensional stability. Our fabrication supports aerospace production by delivering durable tools designed for accuracy and repeatability. These tools help maintain tight manufacturing tolerances and quality control, ensuring consistent part production and smooth assembly processes critical to efficient aerospace manufacturing operations.

Aleaciones

A2, D2, O1, H13

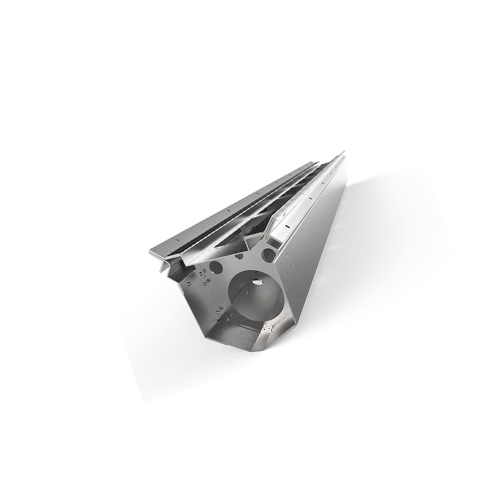

Titanio

Titanium’s high strength-to-weight ratio and corrosion resistance make it ideal for aerospace sheet metal fabrication of engine components, structural supports, and landing gear parts.

DEK expertly handles titanium’s toughness, producing parts like engine mounts, actuator brackets, and fuselage frames with tight tolerances. Our precision fabrication maintains durability and heat resistance critical for aerospace applications, supporting your need for lightweight, robust components that endure extreme conditions and enhance aircraft safety and performance.

Aleaciones

Grade 5 (Ti-6Al-4V)

Al instante & Citas precisas

No utilizamos herramientas de presupuesto automatizadas en línea, porque son muy imprecisas. Las plataformas de presupuesto en línea se basan únicamente en cálculos basados en cantidades de corte y coeficientes fijos, y no tienen en cuenta los matices reales de procesamiento, como la deformación del material tras el tratamiento térmico, requisitos de tolerancia estrictos, rectificado tras el tratamiento térmico, etc. En consecuencia, los cálculos de precios automatizados pueden dar lugar a imprecisiones que, en última instancia, aumentan sus costes.

¡Pero puedes estar tranquilo en DEK!

Nuestros presupuestos son rentables y precisos porque contamos con un equipo de ingenieros mecánicos profesionales que revisan meticulosamente cada dibujo. Estos ingenieros cuentan con más de 10 años de experiencia y poseen profundos conocimientos en programación, funcionamiento de máquinas, posprocesamiento, propiedades de materiales y mucho más. Le garantizamos que obtendrá presupuestos precisos en menos de 6 horas.

Nuestras ventajas

Más de 2300 ingenieros Trabaja con nosotros

Tolerancias estrictas

At DEK, every aerospace part is fabricated with tight tolerances, down to ±0.005 mm, ensuring critical fit, performance, and reliability. Our advanced cutting, forming, and measuring equipment allows us to meet demanding aerospace specs.

Aerospace Grade Materials

We work only with certified aerospace-grade materials. All materials are fully traceable and sourced to meet aerospace compliance standards. This guarantees consistent performance in high-pressure, high-heat environments.

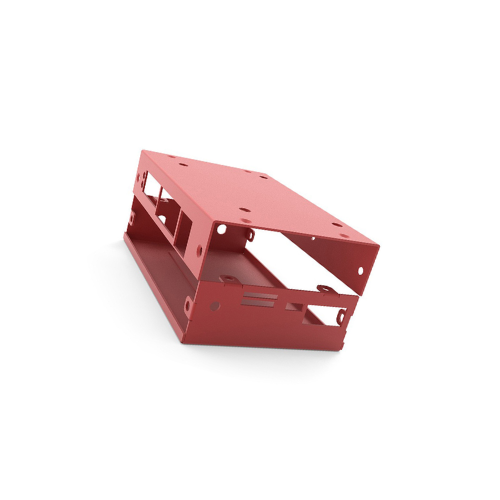

Geometrías complejas

DEK handles complex part designs using advanced equipment and smart processes. We use CNC punching, laser cutting, press braking, and custom jigs to form multi-angled parts, tight bends, and compound curves. Our skilled team brings your challenging geometries to life.

Cost-Effective Production

With DEK, you get high-quality aerospace parts without inflated costs. We streamline setup times, minimize rework with in-process inspections, and reduce waste with efficient nesting and cutting strategies. We help you stay on budget while still meeting tight aerospace specs.

Advanced Surface Finishing

We offer a full range of aerospace-compatible finishes, including anodizing, passivation, powder coating, sandblasting, and polishing. All finishing work is handled in-house to ensure full control over quality and lead time.

Normas de calidad certificadas

DEK operates under AS9100D-certified quality systems and other aerospace requirements, giving you full confidence in every aerospace part we deliver. Every project includes detailed inspections, process controls, and CMM verification to guarantee accuracy and reliability.

Nuestra Proceso de pedido

Enviar petición de oferta

Enviar RFQ con dibujos 2D/3D y requisitos detallados a través de correo electrónico o formulario en línea.

Revisión y presupuesto

Nuestro equipo de ingenieros revisará detenidamente cada plano y le proporcionará un presupuesto preciso en un plazo de 6 horas.

Confirmar pedido

Confirma el presupuesto, los detalles y el plazo de entrega, y luego firma el contrato.

Producción

Organizar el proceso de producción, iniciar la programación y el mecanizado.

Control de calidad

Estricto control de calidad durante la producción y la inspección final.

Embalaje y envío

Empaquete las piezas, coloque las etiquetas de identificación de las piezas y comience el envío.

Enviar RFQ 222

Revisión y presupuesto

Confirmar pedido

Producción

QC

Entrega

PREGUNTAS FRECUENTES

Aerospace Sheet Metal Fabrication Preguntas frecuentes

Obtenga un presupuesto exacto Para sus próximos proyectos

No importa que su proyecto sea complicado o sencillo, no importa que sea de metal o de plástico, obtendrá un presupuesto preciso en un plazo de 6 horas.

Pida presupuesto hoy mismoConocer Aerospace Sheet Metal Fabrication

What is Aerospace Sheet Metal Fabrication?

Aerospace sheet metal fabrication is the process of cutting, bending, and forming thin metal sheets into parts used in aircraft. These parts include panels, brackets, frames, and skins. The process uses specialized tools to meet tight tolerances and aerospace-grade standards, ensuring parts are lightweight, strong, and ready for flight.

In addition to shaping parts, this process also includes finishing steps like deburring, riveting, and surface treatment to prevent corrosion and wear, ensuring long-lasting performance under extreme flight conditions.

What are the Advantages of Aerospace Sheet Metal Fabrication?

This fabrication process supports complex designs and uses certified materials to meet strict requirements for safety and performance. Benefits include:

- Lightweight, high-strength components

- High precision and tight tolerances

- Compatibility with aluminum, titanium, and more

- Quick turnaround for prototyping and production

- Reduced material waste and cost-efficiency

- Reliable quality for critical flight parts

When Do You Need Aerospace Sheet Metal Fabrication?

Use aerospace sheet metal fabrication when building or repairing aircraft components that must handle pressure, vibration, and heat. It is ideal for commercial, military, and private aircraft, including UAVs. You need aerospace fabrication when accuracy, weight savings, and structural performance are critical to your part’s success in flight.

It’s also the right choice when your design involves complex geometries, tight timelines, or certified materials. Whether you’re working on early-stage prototyping or ready-to-fly assemblies, aerospace fabrication helps ensure every part fits perfectly and performs dependably in demanding flight environments.