Mecanizado CNC or computerized numeric control machining is the process of removing the excess material from the workpiece to get the desired part. CNC machining can be done in different ways. CNC milling and CNC turning are the most commonly performed operations in a machine shop. Understanding the difference between these two processes qualifies you to decide the best fit for your project. This article briefly tells about the differences, features, applications advantages, motion, and tool selection of the CNC milling and CNC turning.

¿Qué es el fresado CNC?

Computer numerical control milling or Fresado CNC is a machining process used to cut and drill different materials. It uses multi-point cutting tools to make workpieces and create custom designed products using different materials such as metal, glass wood and plástico. In CNC milling, your tool will rotate and turn while your workpiece will remain in the same position (most of the time). The CNC machine receives commands through Código G that tells it how and at what angles to cut and move along different axes.

¿Qué es el torneado CNC?

Por otro lado, Torneado CNC is the method of creating custom parts using the lathe. As its name suggests the tool remains stationary and does not rotate. Though, the workpiece spins as the cutting tool remains mounted. Workpiece slide can be moved up and down, closer or away to remove the material quickly. CNC turning is computer operated and requires minimal supervision, unlike traditional manual lathe machines.

Features and Benefits of CNC Milling

CNC milling uses sophisticated procedures and ensures precise results. These machines are highly efficient and productive. CNC milling is suitable for a wide range of products and is also cost-effective. Some of the benefits of CNC milling are as below.

- It is replicable, has low labor cost, and precise

- It can mill complex materials with high details

- CNC milling can be used on a variety of materials and it is highly diverse

- It can perform on very low weight to high weight items

- It can perform on multiple-axis which help develop parts with complex geometry

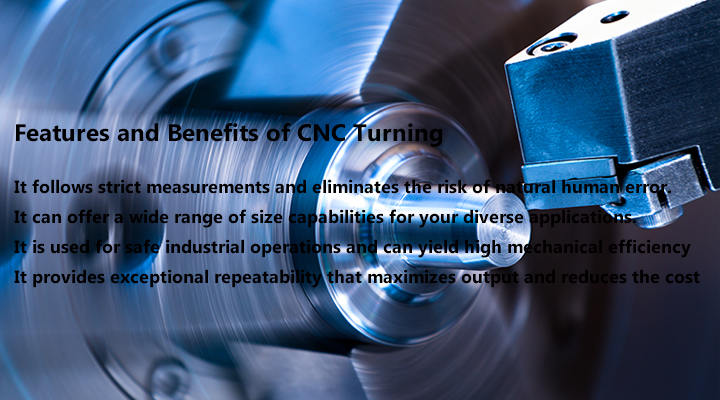

Features and Benefits of CNC Turning

CNC turning is used for creating different products that include shafts, bushings, prototypes, and spacers. You can modify your product by using certain software on your computer. It offers easy installation and durability. Some of the benefits of the CNC turning are as below.

- It follows strict measurements and eliminates the risk of natural human error.

- It can offer a wide range of size capabilities for your diverse applications.

- It is used for safe industrial operations and can yield high mechanical efficiency.

- It provides exceptional repeatability that maximizes output and reduces the cost.

Machining Operations

CNC milling includes machining processes such as face plain and angular milling, while CNC turning includes machining operations such as grooving, boring, drilling, threading, and moleteado.

Motion path of the cutting tool

However, both the machines are used by a variety of industries but their motion path to perform the operation is different. CNC turning uses single-point cutting tools, while CNC milling processes use multi-point cutting tools. CNC milling moves in the vertical and horizontal direction with a rotating cylindrical cutter to create shapes, holes, details, and slots. CNC turning has a chunk that holds the raw material and then spins around the spindle at high speed to remove the excess material and shape the final product.

The Workpiece

CNC milling rotates and moves across the workpiece to carve it and convert it into a finished good. On the other hand, CNC turning requires a workpiece to rotate at the speed and requires the tool to maintain the same place to create the shape.

Máquinas

The CNC milling machines can move in 3 to 5 axes and typically move along three dimensions X, Y, and Z axes. X-axis and Y-axis represent horizontal movement (backwards and forward respectively, on a flat plane), while the Z-axis moves vertical (Up and down). This movement provides great capability and functionality to CNC milling. CNC turning has horizontal and vertical lathes suited for different projects. In a horizontal lathe, the machines hold the workpiece from the side to carve it. While, in the vertical lathe, the machine grips the workpiece from the side to spin it like a top and perform necessary actions to produce the desired item.

Advantages of CNC Milling and CNC Turning

Fresado CNC

CNC milling relies on the computerized control operation that can be used to shape and carve the material. Unlike other CNC subtractive processing method, it is a mechanical process which is used to remove excess material from different objects through a mechanical process rather than chemical, thermal or electrical means.

- The products can be designed even without making a prototype first.

- Dedicated people are not required for each machine, one person can supervise many CNC milling machine

- CNC milling is consistent in replicate the design without defects

- Can act on limitless materials like different metals, plastics, glass, and woods.

Torneado CNC

CNC turning can be used for a wide range of operations like turning, facing, grooving, parting threading, drilling, and more. It can be used on so many materials and their profile could be round, square, hexagonal, or any other. Turning is the basic requirement of every industry due to its high accuracy, reliability, and repeatability.

- CNC turning can be installed with no time and hassle, so you can start making components

- Can produce high-quality products with absolute accuracy in less time comparing to traditional machines

- It has high-end technology for assembly X-axis and Y-axis.

- With the speed of 6000R/M, can make an extremely accurate and smooth finished product.

Selección de herramientas

Tool selection is an art as the machines can perform different functions. Some factors affect your decision to choose the right tool like nature of production, size, and shape of the workpiece, machine type, machining surface roughness, and workpiece material. Below mentioned are the two main types of the tool;

Single-point cutting tool: CNC turning uses the single-point cutting tool. It has only one cutting edge which remains in contact with the workpiece. Since it only has one cutting edge that remains contacted the heat generation is high. If the cutting-edge breaks, the process needs to be paused until replaced. Single-point performs low feed and depth of the cut and productivity is also low as compared to double and multi-point tools. The design of the single-point cutting tool is easier than others.

Multi-point cutting tool: CNC milling uses a multi-point cutting tool. It has more than one (even hundreds) of cutting edges. With so many cutting edges running simultaneously, it engages with the workpiece and removes material quickly to form the final shape. Its fast engagement and disengagement dissipate heat from the cutter thus controlling the temperature rise. If the one cutting edge breaks, you can continue using cutting edge without any issue. When the machine is using a multi-edge cutting tool, it provides a higher feed rate and increases productivity.

Applications of CNC Milling and CNC Turning

Fresado CNC

CNC milling can perform on almost any material. So, their application is near limitless. CNC operations include the plain, face, angular, and form milling. CNC milling can be used from small to medium production runs and suitable for high accuracy and tolerance. Aerospace companies produce prototypes and a wide variety of parts using the CNC milling process. CNC milling precise grooving and improved grip for better packages made it the first choice for the packaging company. It is also used in the consumer market for the prototyping and production of electronic items.

Torneado CNC

CNC turning can perform operations like turning, boring, and threading. It can perform on a wide range of metals like steel, aluminum, titanium, and copper alloys. In plastics, nylon, PE and POM are operational by CNC turning. CNC turning can create a precise component of all types. Industries use CNC turning for both, prototyping and large-batch manufacturing. These kinds of machines are built for high-end precision, spindle speed and hold devices stiff in one place.

Conclusión

There are so many applications of CNC milling and CNC turning depending upon the product requirement of different industries and their functionalities. While they both come under the name CNC machines, they differ in many aspects. But still, they can complement each other. For instance, a turning workpiece may need adding feature with the help of a CNC mill. There are several applications of CNC machining that depend upon the industry you are operating in.

If you are looking for CNC machining that might be CNC milling or CNC turning, DEK should be your first priority. DEK is a world-class demand manufacturing and machining service provider. We have high-end production technologies with strict control to ensure high quality. We deliver affordable and sustainable products to our valuable clients across the globe. Place your order today at DEK to receive your product at your business address. You can also contact our engineers for technical support.