Robotics CNC Machining Service

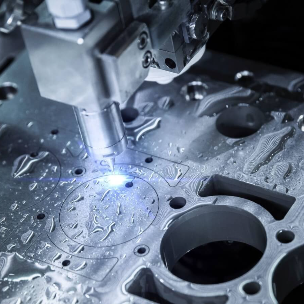

Robotics CNC machining creates precise robot parts using computer-guided machines to cut metal and plastic, ideal for prototypes or mass production with high accuracy and customization.

With DEK, you can order a variety of custom parts that are tailored to your specific production and project requirements. We offer fast quotes, no minimum order, affordable pricing, and high precision. Our quick turnaround, many finishing options, and strong quality control ensure parts are made exactly as needed.

introducción

Robotics CNC Machining: Precision Parts Made Easy

DEK offers high-precision robotics CNC machining services, delivering custom metal and plastic parts quickly and accurately to support robotics prototyping, production, and specialized component needs.

Here at DEK, our robotics CNC machining services are tailored to deliver high-quality, custom components for robotic systems of all sizes and functions. Our advanced CNC equipment includes 3-axis and 5-axis machining centers, Swiss turning machines, and precision grinders that enable us to produce complex parts with tight tolerances. We offer prototyping, low-volume runs, and full-scale production of robotic parts, ensuring each part meets the high standards of robotic applications.

In order to meet different robotic needs, we use a variety of materials, including aluminum, stainless steel, titanium, and engineering plastics such as PEEK and Delrin. With DEK, you are guaranteed to get the right parts on time, in the right quantities, and of the right quality, whether you need lightweight parts for drones or durable joints for industrial robots.

- 5-axis CNC with Swiss turning

- Precision up to ±0.005 mm

- Prototypes delivered as fast as 1 day

- Wide range of metals and plastics

- Sin cantidad mínima de pedido

- Fast, reliable global shipping

Materiales for Robotics CNC Machining

Metales

Plásticos

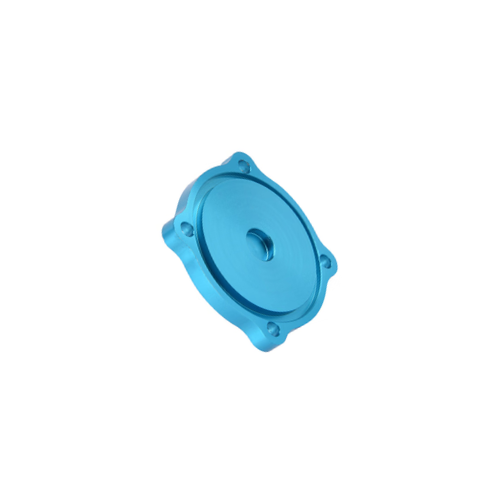

Aluminio

Aluminum is a popular alloy in robotics CNC machining due to its great strength-to-weight ratio, corrosion resistance, and ease of machining. It’s perfect for drone frames, robotic arms, and aerospace parts that need to be strong yet lightweight.

At DEK, we specialize in high-precision robotics CNC machining of various aluminum alloys for robotics and other demanding applications. Our services ensure reliable, cost-effective, and high-quality results tailored to meet performance standards across industries.

Aleación

AL6061, AL6063, AL5083, AL5052, etc.

Latón

Brass is highly valued in CNC machining for its excellent machinability, low friction, and natural corrosion resistance. It’s commonly used in electronics and robotic connectors, especially for parts that involve rotation or sliding. Its smooth finish also adds visual appeal.

DEK offers precision brass machining to produce high-quality, durable, and reliable components for the robotics industry, ensuring each part meets strict functional and aesthetic standards for demanding applications.

Aleación

Latón 260, C360, Cz121, etc.

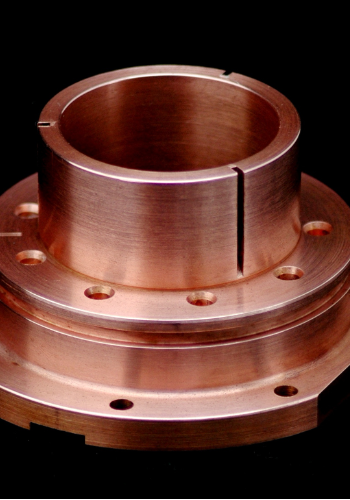

Cobre

Copper is widely used in CNC machining for its exceptional electrical and thermal conductivity, making it ideal for connectors, wiring housings, and heat sinks in robotics. Although too soft for structural parts, it’s essential where electrical performance is critical.

DEK specializes in precision copper machining, providing reliable, high-quality components for advanced electronic and thermal applications in robotics and automation, ensuring optimal performance where conductivity and heat management are key.

Aleación

Cobre C101, C110, etc.

Inconel

Inconel is a high-performance superalloy known for its outstanding resistance to heat, pressure, and wear, making it ideal for extreme environments. Commonly used in aerospace and defense robotics, it performs exceptionally well under high-stress, high-temperature conditions. Though difficult to machine, its unmatched strength and stability are crucial for mission-critical applications.

At DEK, we offer expert CNC machining of Inconel, delivering precise, durable components tailored for the most demanding robotic and industrial uses.

Aleación

Inconel 718, 625, 600, etc.

Acero dulce

Mild steel is a popular choice in robotics for structural and mechanical parts, thanks to its good strength, machinability, and affordability. It’s ideal for frames, brackets, and fixtures that must handle mechanical stress without requiring corrosion resistance.

DEK provides high-precision robotics CNC machining of mild steel, delivering durable and reliable components tailored for various industrial and robotic applications, ensuring consistent performance and cost-effective solutions for your engineering needs.

Aleación

Acero dulce 1018, 1045, A36, 1215, etc.

Acero inoxidable

Stainless steel is prized for its exceptional corrosion resistance and strength, making it ideal for robotic parts exposed to moisture, chemicals, or high wear. Commonly used in joints, frames, and support structures, it provides long-lasting durability, even though it’s heavier than aluminum.

At DEK, we specialize in precision CNC machining of stainless steel, producing reliable, high-performance components tailored for demanding robotic and industrial environments where strength and resilience are essential.

Aleación

Acero inoxidable 301, 303, 304, 304L, 316, 316L, etc.

Titanio

Titanium offers an outstanding strength-to-weight ratio, making it perfect for high-performance robotics and drone components. Commonly used for motor mounts, fasteners, and structural parts, it combines durability with low weight. Its excellent corrosion resistance also makes it ideal for outdoor and marine environments.

DEK specializes in precision CNC machining of titanium, producing reliable, high-quality parts tailored for demanding, weight-sensitive applications in robotics, aerospace, and other advanced engineering industries.

Aleación

Titanio Grado 1, Grado 2, Grado 5, etc.

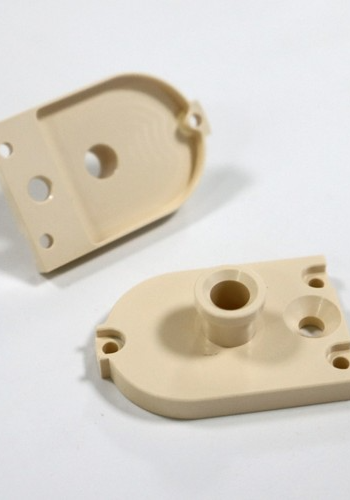

ABS

ABS is a durable, impact-resistant plastic widely used for drone housings, enclosures, and internal mounts. It’s lightweight, easy to machine, and cost-effective, making it an excellent choice for prototyping and production of protective parts. Its strength-to-weight balance ensures reliable performance in various robotics applications.

At DEK, we provide high-quality CNC-machined ABS components, including covers, mounting plates, and structural elements, all crafted with precision to meet the demands of both testing phases and final deployment.

Delrin

Delrin is a strong, low-friction plastic perfect for high-precision moving parts in robotics and drones. It offers excellent dimensional stability, wear resistance, and smooth motion, making it ideal for gears, bearings, rollers, and other components that require consistent performance. Lightweight and non-conductive, Delrin is also suited for electrical isolation needs.

DEK specializes in CNC machining Delrin to tight tolerances, producing durable, high-quality parts tailored for dynamic robotics systems and demanding mechanical assemblies where precision and reliability are essential.

HDPE

HDPE is a lightweight, moisture-resistant plastic known for its toughness and ease of machining. It’s commonly used in robotics for panels, spacers, and containers, and in drone CNC machining for battery mounts, landing gear, and other non-load-bearing components. Its durability, impact resistance, and low weight make it perfect for functional applications that demand reliability without added mass.

At DEK, we deliver precision-machined HDPE parts designed for rugged, lightweight performance in drone assemblies and various robotic systems.

Nylon

Nylon is a strong, flexible plastic known for its excellent wear, impact, and chemical resistance. It’s commonly used in robotics for bushings, washers, insulators, and components that require flexibility and durability. In drone CNC machining, Nylon is especially valued for its vibration absorption and resistance to cracking under stress, helping ensure smooth, reliable operation.

At DEK, we specialize in machining high-performance nylon parts, delivering precise, resilient components built to withstand dynamic movement and harsh environments in both robotic applications.

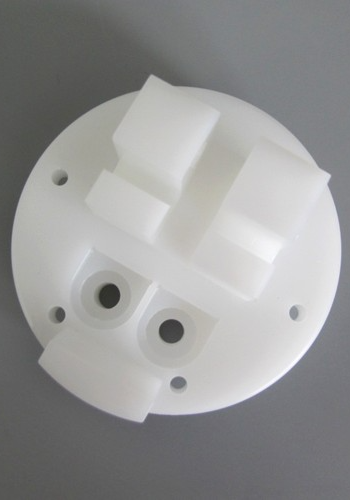

PEEK

PEEK is a high-performance engineering plastic prized for its exceptional resistance to heat, chemicals, and mechanical stress. Commonly used in robotics and aerospace, it’s ideal for applications requiring long-term reliability, cleanliness, and durability under extreme conditions. Although more expensive than other plastics, PEEK offers outstanding dimensional stability and toughness, making it perfect for precision components.

DEK specializes in machining high-quality PEEK parts tailored for advanced robotic and aerospace systems where performance, accuracy, and endurance are essential.

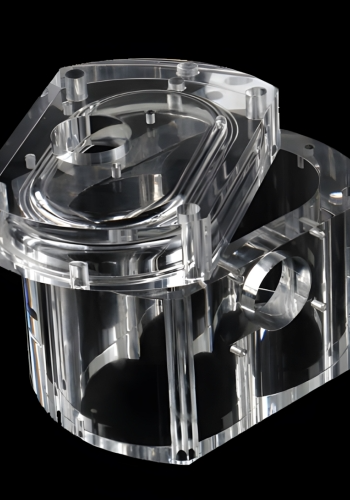

Policarbonato

Polycarbonate is a tough, transparent plastic known for its high impact resistance, making it ideal for protective shields, covers, and lenses in robotic systems. It combines excellent strength with light weight and heat resistance, offering both durability and clarity. Its precise machinability makes it a top choice for safety-critical parts where visibility and reliability are key.

DEK offers machining of high-quality polycarbonate components tailored for demanding robotic applications that require strong, lightweight, and transparent protection.

PTFE

PTFE is a soft, chemically resistant plastic ideal for robotics CNC machining where low friction and high temperature resistance are essential. Commonly used for seals, gaskets, and insulation parts, PTFE excels in harsh environments involving heat, chemicals, and mechanical stress. While less rigid than other plastics, its non-stick and durable properties make it vital for specialized applications.

DEK produces high-precision PTFE components designed to perform reliably in extreme thermal, chemical, and mechanical conditions within advanced robotic systems.

Al instante & Citas precisas

No utilizamos herramientas de presupuesto automatizadas en línea, porque son muy imprecisas. Las plataformas de presupuesto en línea se basan únicamente en cálculos basados en cantidades de corte y coeficientes fijos, y no tienen en cuenta los matices reales de procesamiento, como la deformación del material tras el tratamiento térmico, requisitos de tolerancia estrictos, rectificado tras el tratamiento térmico, etc. En consecuencia, los cálculos de precios automatizados pueden dar lugar a imprecisiones que, en última instancia, aumentan sus costes.

¡Pero puedes estar tranquilo en DEK!

Nuestros presupuestos son rentables y precisos porque contamos con un equipo de ingenieros mecánicos profesionales que revisan meticulosamente cada dibujo. Estos ingenieros cuentan con más de 10 años de experiencia y poseen profundos conocimientos en programación, funcionamiento de máquinas, posprocesamiento, propiedades de materiales y mucho más. Le garantizamos que obtendrá presupuestos precisos en menos de 6 horas.

Nuestras ventajas

Más de 2300 ingenieros Trabaja con nosotros

Tolerancias estrictas

Robotics CNC machining delivers extremely accurate parts with tight tolerances, often up to ±0.005 mm. This level of precision is critical for robotic components, which require perfect alignment and smooth operation.

Respuesta rápida

CNC machining enables fast production of robotic parts, ideal for tight deadlines or time-sensitive projects. This rapid turnaround helps businesses speed up development, reduce downtime, and bring robotics products to market faster without sacrificing quality.

Flexibilidad de volumen

Whether you need one prototype or thousands of parts, CNC machining offers full flexibility. There’s no minimum order requirement, making it cost-effective for startups, R&D teams, and large manufacturers alike.

Versatilidad de materiales

Robotics CNC machining supports a wide range of materials. This flexibility allows engineers to choose the best material for strength, weight, and environmental resistance, depending on the robot’s function and working conditions.

Geometrías complejas

In robotics CNC machining, custom-shaped components, curved surfaces, and multi-face features are common. It ensures functional, space-efficient parts with minimal need for additional assembly.

Relación coste-eficacia

CNC machining offers an excellent balance of quality and cost, especially for precision robotics components. With efficient processes, minimal waste, and low labor needs, it provides high-value parts at a competitive price.

Nuestra Proceso de pedido

Enviar petición de oferta

Enviar RFQ con dibujos 2D/3D y requisitos detallados a través de correo electrónico o formulario en línea.

Revisión y presupuesto

Nuestro equipo de ingenieros revisará detenidamente cada plano y le proporcionará un presupuesto preciso en un plazo de 6 horas.

Confirmar pedido

Confirma el presupuesto, los detalles y el plazo de entrega, y luego firma el contrato.

Producción

Organizar el proceso de producción, iniciar la programación y el mecanizado.

Control de calidad

Estricto control de calidad durante la producción y la inspección final.

Embalaje y envío

Empaquete las piezas, coloque las etiquetas de identificación de las piezas y comience el envío.

Enviar RFQ 222

Revisión y presupuesto

Confirmar pedido

Producción

QC

Entrega

PREGUNTAS FRECUENTES

Robotics CNC Machining Preguntas frecuentes

Obtenga un presupuesto exacto Para sus próximos proyectos

No importa que su proyecto sea complicado o sencillo, no importa que sea de metal o de plástico, obtendrá un presupuesto preciso en un plazo de 6 horas.

Pida presupuesto hoy mismoConocer Robotics CNC Machining

What is Robotics CNC Machining Service?

Robotics CNC machining service is a specialized service that creates precise parts used in building robots. It uses computer-controlled machines to cut and shape materials like metal and plastic into custom parts, such as robot arms, joints, and frames. This process helps ensure each piece fits perfectly and works reliably, whether for a prototype or mass production. It's a fast, accurate, and reliable way to make the parts needed for modern robotics.

These services are helpful for many industries, including manufacturing, healthcare, and automation. CNC machining supports the development of everything from factory robots to medical devices, making it easier to bring complex ideas to life. Whether you're designing a brand-new robot, upgrading an existing one, or replacing a worn-out part, CNC machining gives you the precision and quality needed to get the job done right. With its ability to produce parts quickly and consistently, it’s an essential tool for anyone working in robotics.

What are the Advantages of Robotics CNC Machining Services?

Robotics CNC machining services offer several advantages that make them a reliable choice for creating high-quality robotic parts. These services ensure accuracy, consistency, and flexibility, making them ideal for both simple and complex components across various industries.

Here are the benefits of robotics CNC machining services:

- Exact measurements for a perfect fit

- Same high quality every time

- Quickly delivers parts

- Various material options

- Matches your exact design

- Prototypes and large production

When Do You Need Robotics CNC Machining Services?

You need robotics CNC machining services when you require custom, high-precision parts for building or repairing robots. This is especially important when commercially available parts don’t fit your design or when you’re creating a new robot with unique features. Whether it’s a robotic arm, joint, or base, CNC machining ensures each part is made accurately to match your specifications.

These services are also helpful during prototyping or testing, allowing you to quickly create and adjust parts before full production. With CNC machining, it's easy to test different designs and make changes on the fly, helping you avoid costly delays or errors later on. If you need durable components made from specific materials like aluminum or plastic, or you're working on a tight deadline, CNC machining offers a fast and dependable solution. It gives engineers and designers the flexibility to bring their ideas to life without compromising on quality or speed.