Metal 3D Printing Service

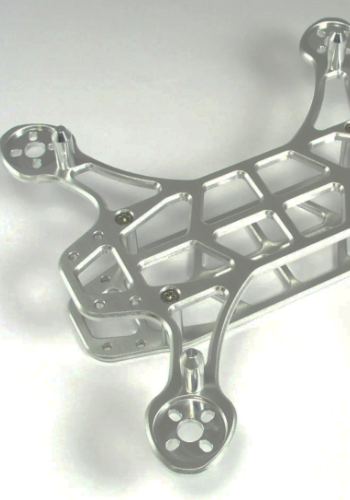

Parts are printed based on individual 3D design files, enabling customization and personalization in both function and aesthetics without high tooling costs. Go for metal 3D printing if low to medium volumes where customization, weight, and lead time are needed.

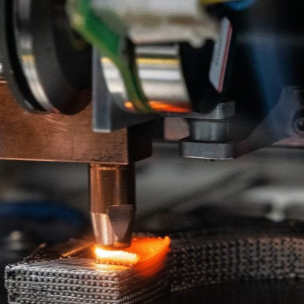

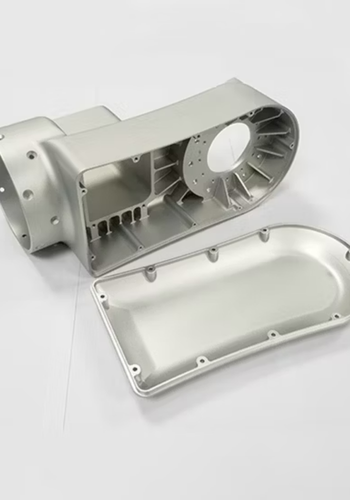

DEK provides comprehensive metal 3D printing services using advanced powder bed fusion technology and high-performance alloys like aluminum and titanium. Unlike many competitors, DEK integrates additive and subtractive manufacturing, in-house finishing, and ISO-compliant quality control. Our engineering expertise ensures optimized designs, faster turnaround, and cost-effective, production-ready parts.

introducción

High-Precision Impresión 3D en metal

DEK offers precision metal 3D printing services using advanced powder bed fusion technology, delivering complex, lightweight, and fully functional parts with integrated finishing and ISO-certified quality assurance.

Our facility is equipped with advanced metal printers capable of working with materials like aluminum, titanium, stainless steel, and other performance alloys. From concept to final part, we support customers through the full process, including design optimization, support structure planning, printing, post-processing, and quality inspection. Whether for prototypes or small-to-medium production runs, DEK ensures each part meets industry standards and functional requirements. In addition to printing, DEK offers integrated post-processing services, such as heat treatment, CNC machining, and surface finishing, all performed under strict ISO-certified quality control. Our team provides guidance on design, helping clients reduce material use, improve performance, and shorten production time.

By using both 3D printing and machining, we create high-quality metal parts faster, at lower cost, and with reliable results for industries like aerospace, medical, and automotive.

- Advanced PBF equipment

- Wide material selection

- Integrated finishing solutions

- ISO-certified processes

- Expert design support

- Fast project turnaround

Materiales for Metal 3D Printing

Metales

Aluminio

Aluminum is a lightweight, corrosion-resistant metal widely used in metal 3D printing for its excellent thermal conductivity and ease of machining. It is commonly used in aerospace, automotive, and consumer industries where weight reduction is critical.

DEK offers precise aluminum metal 3D printing services that produce parts like housings, brackets, and heat exchangers. Our technology ensures tight tolerances, smooth finishes, and quick turnaround times, making aluminum ideal for both prototypes and production parts.

Aleación

AL6061, AL6063, AL5083, AL5052, etc.

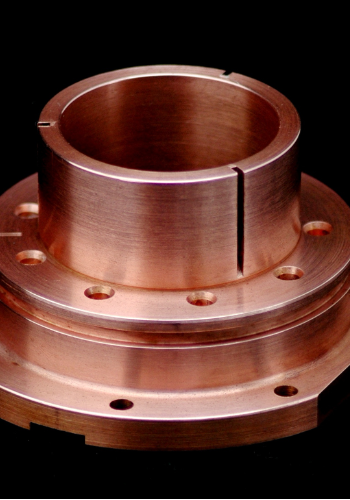

Cobre

Copper is valued for its exceptional electrical and thermal conductivity, corrosion resistance, and machinability. It is widely used in electrical components, heat exchangers, and RF devices.

We offer precision copper metal 3D printing services that create intricate, conductive parts such as inductors and heat sinks. Our metal 3D printing ensures dimensional accuracy, smooth finishes, and consistent material performance, making copper ideal for both functional prototypes and end-use components in high-performance applications.

Aleación

Cobre C101, C110, etc.

Inconel

Inconel is a high-strength, corrosion-resistant nickel-based metal ideal for extreme environments like aerospace and power generation. Its excellent oxidation resistance allows it to maintain mechanical integrity at elevated temperatures.

DEK specializes in Inconel metal 3D printing, producing complex, heat-resistant parts such as turbine blades and exhaust components. Our advanced metal 3D printing process guarantees precise geometries, durability, and consistent performance for applications requiring strength under severe thermal and mechanical stress.

Aleación

Inconel 718, 625, 600, etc.

Magnesio

Magnesium is one of the lightest structural metals, offering a unique combination of strength, low density, and good thermal conductivity. It is used in aerospace, automotive, and lightweight engineering applications.

DEK provides metal 3D printing for magnesium components, delivering lightweight yet strong parts with intricate designs. Our process ensures dimensional accuracy and repeatable quality for prototypes and end-use applications.

Aleación

MgAZ318, MgAZ61B, MgAZ91D, etc.

Acero inoxidable

Stainless steel is a versatile metal known for its strength, corrosion resistance, and weldability, used across medical, industrial, and structural applications. It supports hygienic and durable components.

We use metal 3D printing to produce stainless steel parts with tight tolerances and excellent surface finishes. We manufacture intricate parts like surgical tools and mechanical brackets with consistent quality, enabling rapid prototyping and small- to medium-scale production for industries demanding robust metal components.

Aleación

Acero inoxidable 301, 303, 304, 304L, 316, 316L, etc.

Titanio

Titanium is a strong, lightweight, and corrosion-resistant metal widely used in aerospace, medical implants, and high-performance engineering. It offers an excellent strength-to-weight ratio and biocompatibility.

DEK provides titanium metal 3D printing services capable of producing complex geometries like surgical implants, brackets, and housings. Our technology delivers parts with precise dimensions, high durability, and smooth finishes, ideal for critical applications where weight savings and material performance are essential.

Aleación

Titanio Grado 1, Grado 2, Grado 5, etc.

Acero para herramientas

Tool steels are high-hardness metals designed for wear resistance, toughness, and durability, commonly used in tooling, molds, and dies. They withstand high loads and mechanical stresses.

DEK offers metal 3D printing for tool steel parts requiring complex shapes and superior mechanical properties. Our process ensures dimensional accuracy, repeatability, and long tool life, making it suitable for injection mold inserts, cutting tools, and custom tooling components in demanding manufacturing environments.

Aleación

Acero para herramientas A2, A3, D2, S7, etc.

Al instante & Citas precisas

No utilizamos herramientas de presupuesto automatizadas en línea, porque son muy imprecisas. Las plataformas de presupuesto en línea se basan únicamente en cálculos basados en cantidades de corte y coeficientes fijos, y no tienen en cuenta los matices reales de procesamiento, como la deformación del material tras el tratamiento térmico, requisitos de tolerancia estrictos, rectificado tras el tratamiento térmico, etc. En consecuencia, los cálculos de precios automatizados pueden dar lugar a imprecisiones que, en última instancia, aumentan sus costes.

¡Pero puedes estar tranquilo en DEK!

Nuestros presupuestos son rentables y precisos porque contamos con un equipo de ingenieros mecánicos profesionales que revisan meticulosamente cada dibujo. Estos ingenieros cuentan con más de 10 años de experiencia y poseen profundos conocimientos en programación, funcionamiento de máquinas, posprocesamiento, propiedades de materiales y mucho más. Le garantizamos que obtendrá presupuestos precisos en menos de 6 horas.

Nuestras ventajas

Más de 2300 ingenieros Trabaja con nosotros

Material Flexibility

DEK works with a broad range of metals, including aluminum, titanium, stainless steel, Inconel, cobalt-chrome, and custom metal powders. This material flexibility enables engineers to choose the best metal for strength, weight, heat resistance, or corrosion protection.

Tolerancias estrictas

DEK achieves excellent precision in metal 3D printed parts, with tolerances typically within ±0.005 mm. This level of accuracy ensures that parts fit and function as intended, even in high-performance applications.

Acabados personalizados

DEK offers multiple post-processing options for metal parts, such as polishing, sandblasting, bead blasting, and coating. These finishing processes enhance surface aesthetics, wear resistance, and corrosion protection.

No Order Limits

DEK supports flexible production volumes with no minimum order quantity. Whether you need a single prototype or a low-to-mid-volume production run, DEK adapts to your needs. Explore metal 3D printing without committing to large batch quantities or high upfront manufacturing costs.

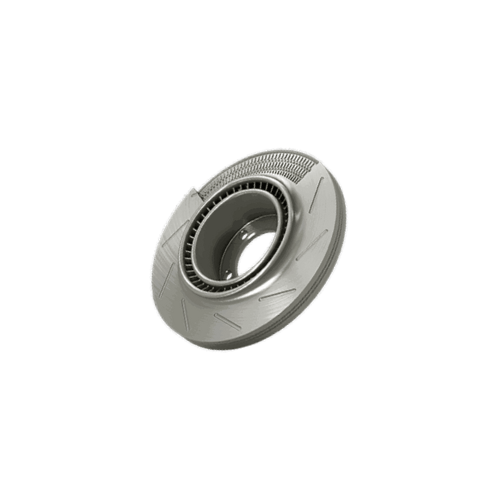

Complex Geometry Printing

DEK’s metal 3D printers can produce highly intricate geometries, including internal channels, lattice structures, overhangs, and organic shapes. This design freedom is ideal for lightweighting, fluid flow optimization, and part consolidation.

Cost-Effective Production

Metal 3D printing at DEK reduces overall production costs by minimizing waste, eliminating tooling, and shortening development timelines. Especially for low-to-mid volume orders or complex geometries, additive manufacturing becomes significantly more economical than traditional CNC or casting methods.

Nuestra Proceso de pedido

Enviar petición de oferta

Enviar RFQ con dibujos 2D/3D y requisitos detallados a través de correo electrónico o formulario en línea.

Revisión y presupuesto

Nuestro equipo de ingenieros revisará detenidamente cada plano y le proporcionará un presupuesto preciso en un plazo de 6 horas.

Confirmar pedido

Confirma el presupuesto, los detalles y el plazo de entrega, y luego firma el contrato.

Producción

Organizar el proceso de producción, iniciar la programación y el mecanizado.

Control de calidad

Estricto control de calidad durante la producción y la inspección final.

Embalaje y envío

Empaquete las piezas, coloque las etiquetas de identificación de las piezas y comience el envío.

Enviar RFQ 222

Revisión y presupuesto

Confirmar pedido

Producción

QC

Entrega

PREGUNTAS FRECUENTES

Metal 3D Preguntas frecuentes

Obtenga un presupuesto exacto Para sus próximos proyectos

No importa que su proyecto sea complicado o sencillo, no importa que sea de metal o de plástico, obtendrá un presupuesto preciso en un plazo de 6 horas.

Pida presupuesto hoy mismoImpresión 3D en metal Perspectivas

What is Metal 3D Printing?

Metal 3D printing refers to various additive manufacturing processes that construct metal parts layer-by-layer from 3D model data without the constraints of traditional subtractive methods. The most common technologies used are powder bed fusion, directed energy deposition, and binder jetting.

A focused heat source like a laser or electron beam selectively melts and fuses metallic powder or wire in thin layers based on cross-sectional slices of the 3D CAD model to build up a physical object. A wide range of metals can be printed, from stainless steel and titanium to nickel alloys, aluminum, and cobalt chrome. Compared to conventional manufacturing, this approach offers highly innovative design freedom for complex, lightweight, and customized geometries. Metal 3D printing excels at rapid prototyping, bridge tooling, and low to medium volume production.

What are the Advantages of Metal 3D Printing?

Metal 3D printing enables the production of high-performance components with greater speed, flexibility, and design freedom than traditional manufacturing.

- Lightweight structures

- Reduced material waste

- No tooling needed

- Creación rápida de prototipos

- Flexible production

- Faster turnaround

- Fewer assemblies

- Strong, durable parts

- Low-volume efficiency

- Optimized material use

- Custom designs

When Do You Use Metal 3D Printing?

Metal 3D printing is great for projects that require quick production, detailed customization, or small batches without the need for molds or tools. For example, in aerospace, it’s used to make engine parts, brackets, and heat exchangers that must perform under extreme conditions. In the medical field, doctors and dentists use it to create custom implants, surgical tools, and prosthetics made to fit each patient perfectly.

This technology is also widely used in the automotive industry to design and test lightweight parts quickly, such as exhaust manifolds or heat shields. In factories, it helps produce useful tools, jigs, and fixtures that support day-to-day manufacturing tasks. Metal 3D printing is also popular in fields like architecture, jewelry, and consumer electronics, where detailed and artistic metal designs are needed. Even in research labs, it’s used to create metal samples for testing and experiments.