- Inicio

- Materiales

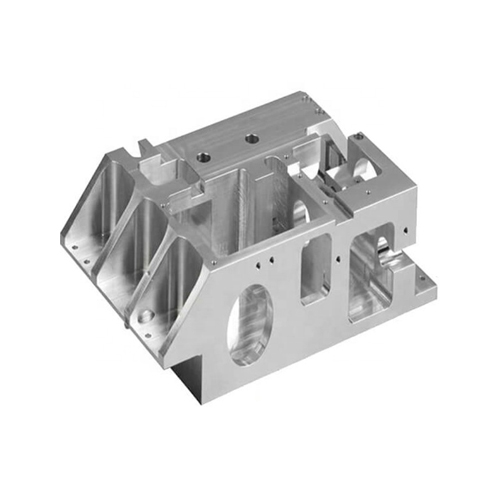

- Mecanizado CNC de metales

- Aluminio

- Aluminio MIC6

Aluminio MIC6

Tipo de material

Metal

Nombre del material

Aluminio MIC6

Compatibilidad de procesos

Fresado CNC, Torneado CNC

Aluminio MIC6 en Mecanizado CNC

MIC-6 is a cast aluminum plate made from a mix of metals. It offers high accuracy and easy machinability. The casting process gives it stress-relieving properties

MIC6 is highly used for precision CNC machining due to its outstanding flatness and stability. It possesses a fine-grain structure that enhances mechanical properties. It is lightweight, smooth, and free from tension, contaminants, and porosity. With excellent thermal conductivity, MIC6 effectively dissipates heat during machining, reducing the risk of thermal distortion. This material's machinability makes cutting, milling, and drilling easy. Manufactured with tight dimensional tolerances, MIC6 guarantees consistency and precision in the final product, remaining stable under varying temperatures.

MIC6 has a smooth surface finish, improving the machined parts' surface quality. Anodizing capability allows surface hardness, corrosion resistance, and wear resistance enhancements. Despite being pricier than standard aluminum alloys, MIC6's distinct properties and advantages in precision applications justify its cost. Standard sizes are readily available, facilitating convenience in CNC machining projects.

Tabla de propiedades of Aluminum MIC6

| PROPIEDADES MECÁNICAS | |

|---|---|

| Resistencia a la tracción | 160-170 MPa |

| Límite elástico | 70-130 MPa |

| Módulo de Young (elasticidad) | 71 GPa |

| Alargamiento a la rotura | 3-7 % |

| Propiedades físicas | |

| Resistencia a la corrosión | Bien |

| Magnetismo | No magnético |

| Soldabilidad | Bien |

| Propiedades térmicas | |

| Temperatura máxima de servicio | 427°C |

| Coeficiente de dilatación térmica | 23.6-24.5 x 10^-6/°C |

| Conductividad térmica | 142 W/(m·°C) |

| Propiedades eléctricas | |

| Resistividad eléctrica | 4.79 μΩ*cm |

Conocimientos básicos of Aluminum MIC6

What is Aluminum MIC6?

MIC6 is a precision cast aluminum tooling plate known for its superior flatness, stability, and machinability. The fine-grained structure of MIC6 ensures exceptional dimensional stability. Its ability to undergo anodizing further enhances its corrosion resistance and aesthetics.

With excellent thermal conductivity, MIC6 efficiently dissipates heat. The plate's reliability and ease of machining contribute to its popularity in producing precise components and tooling.

Advantages of Aluminum MIC6

- Excellent flatness and stability

- Ideal for precision machining applications

- Low internal stress and tight thickness tolerance

- Uniform hardness for enhanced machining performance

- Cast plate structure reduces the need for extensive post-machining processes

Applications of Aluminum MIC6

- Machined fixtures and tooling plates for aircraft parts

- High-precision chassis and enclosures

- Inspection gauges and jigs

- Precision components in medical imaging machines

- Tooling used in the fabrication of lenses and other optical elements.

Machining Aluminum MIC6 Preguntas frecuentes

Otros Materiales

Aluminio 7075

El aluminio 7075 es una aleación resistente y ligera que suele elegirse por su elevada relación resistencia-peso. Se utiliza ampliamente en el mecanizado CNC

Aluminio 6063

El aluminio 6063 se compone principalmente de aluminio, magnesio y silicio. Su excelente mecanizabilidad hace que se utilice habitualmente en procesos CNC.

Aluminio 6061

El aluminio 6061 (CNC) es la aleación de aluminio más popular. Tiene una buena relación resistencia-peso, excelente mecanizabilidad y resistencia natural a la corrosión.

Obtenga un presupuesto exacto Para sus próximos proyectos

No importa que su proyecto sea complicado o sencillo, no importa que sea de metal o de plástico, obtendrá un presupuesto preciso en un plazo de 6 horas.

Pida presupuesto hoy mismo