- Inicio

- Oil & Gas

High Quality Custom Oil & Gas Parts Manufacturing

DEK has been specializing in the precision manufacturing of machined parts for the Oil & Gas industry, and we offer high-quality, durable components with industry-leading speed to customers around the world at cost-effective prices. We can quickly machine complex parts with tight tolerances of +/- 0.005mm, a wide range of production grade materials, and surface finish options. Get instant quote!

- Competitive Price & Reliable

- 24/7 Engineering Support & DFM

- ISO 9001:2015 Certified.

- Entrega rápida, plazo de entrega corto, sin MOQ

Precision Parts Manufacturing in the Petróleo y gas

DEK is renowned for our outstanding quality and exceptional customer service, providing precision machining of custom parts for the oil and gas industry. Our parts are reliably applied in the high-speed, high-volume, and corrosive environments commonly found in this industry.

As an ISO 9001-certified manufacturer, DEK possesses top-tier machining capabilities, achieving precision tolerances as tight as ±0.005mm. We strictly adhere to industry standards such as API and NACE, and specialize in machining specialty corrosion-resistant materials like Hastelloy, Inconel, and Monel, ensuring that every part processed by DEK delivers exceptional performance and durability.

Additionally, we offer surface treatments such as anodizing, QPQ, electroplating, nitriding, and Passivation. Our typical applications include MWD/LWD parts, drill string components, downhole motors, casing, and cementing accessories. We provide a fast, transparent quoting process and clear production scheduling, along with CMM inspection reports, FAI reports, and material certificates. Contact us today to reduce your total cost of ownership (TCO).

Turned Part

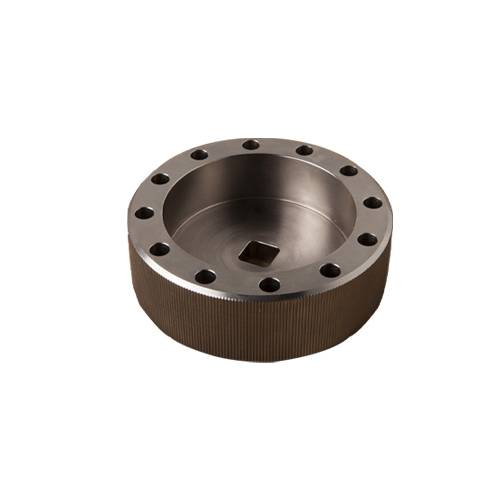

Machined Part

Eje de precisión

Eje de precisión

Colgador de tubos

Oil & Gas Component Capacidad de fabricación

Mecanizado CNC de precisión

DEK offers fast, accurate, and reliable CNC precision machining. Our strict tolerances can reach ±0.005mm, making us ideal for precision leak-proof rotation chuck parts, seal parts, casing heads, flanges, and connectors.

We specialize in precision parts machining for the oil and gas industry, with expertise in 5-axis machining of complex parts. We offer rapid prototyping services and free DFM analysis to reduce costs. Whether you need a functional prototype or are seeking a reliable partner for small-batch production, DEK provides flexible and efficient solutions.

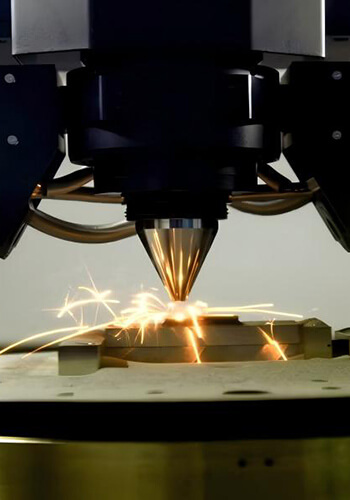

Impresión 3D industrial

DEK offers high-quality additive manufacturing technologies, including metal 3D printing, SLA, SLS, and FDM. We help you create rapid prototypes at low cost and produce high-precision, durable, corrosion-resistant parts.

We offer a variety of metals and plastics, including stainless steel, Inconel, and PTFE, for printing Inconel 718 turbine blades, mixed nozzles, or heat exchanger components. Additionally, we can provide surface treatments as required for your project, such as heat treatment, nitriding, QPQ, and PTFE coating.

Fabricación de chapas metálicas

DEK specializes in manufacturing high-quality custom sheet metal parts for the oil and gas industry. From equipment skids to electrical control cabinets, we provide reliable structural support and protection for your core equipment.

We offer a variety of sheet metal materials, including aluminum, stainless steel, steel, brass, and copper. From instant quotes to rapid production, you can obtain over 300 high-quality sheet metal parts in just a few days. Additionally, we provide surface treatment options to meet your parts' high-demand requirements.

Moldeo por inyección de plásticos

DEK offers high-performance injection molding for the Oil & Gas industry. We specialize in advanced polymers like PEEK, PPS, PTFE, and PEI for critical seals, insulators, and wear components.

Our expert mold design and rigorous process control ensure exceptional dimensional accuracy and tight tolerances. We focus on material stability and creep resistance, guaranteeing reliable, consistent components for your most critical high-pressure, high-temperature (HPHT) applications.

Materiales

Materiales Opciones

Acero inoxidable

This high-performance metal is renowned for its excellent corrosion resistance, high strength, and resistance to high and low temperatures, making it the material of choice for offshore platform structural components, fasteners, impellers, and shafts.

Acero al carbono

Carbon steel has high strength, excellent workability, and weldability. It is widely used in the oil & gas industry and is ideal for manufacturing pressure-bearing components, structural parts, and downhole tools. In addition, we also offer DLC coating and PVD coating.

Acero aleado

Alloy steel is a high-strength, high-temperature resistant, and wear-resistant metal. It is the preferred material for drill pipes, flanges, tubing heads, high-pressure fasteners, and connectors, and it has excellent low-temperature impact toughness and good machinability.

Inconel

Inconel is a nickel-chromium-based superalloy with outstanding high-temperature strength and creep resistance, superior corrosion resistance, and extreme temperature adaptability. It is ideal for use in subsea Christmas trees, turbine blades, high-temperature bolts, and springs.

Al instante & Citas precisas

No utilizamos herramientas de presupuesto automatizadas en línea, porque son muy imprecisas. Las plataformas de presupuesto en línea se basan únicamente en cálculos basados en cantidades de corte y coeficientes fijos, y no tienen en cuenta los matices reales de procesamiento, como la deformación del material tras el tratamiento térmico, requisitos de tolerancia estrictos, rectificado tras el tratamiento térmico, etc. En consecuencia, los cálculos de precios automatizados pueden dar lugar a imprecisiones que, en última instancia, aumentan sus costes.

¡Pero puedes estar tranquilo en DEK!

Nuestros presupuestos son rentables y precisos porque contamos con un equipo de ingenieros mecánicos profesionales que revisan meticulosamente cada dibujo. Estos ingenieros cuentan con más de 10 años de experiencia y poseen profundos conocimientos en programación, funcionamiento de máquinas, posprocesamiento, propiedades de materiales y mucho más. Le garantizamos que obtendrá presupuestos precisos en menos de 6 horas.

Por qué elegir Nuestros servicios

La producción única de piezas de alta calidad le ahorra tiempo y dinero.

Capacidades de ingeniería

Plazo de entrega rápido

Acabados superficiales

Control de calidad

Montaje de precisión

Packaging and Logistics

Nuestra Proceso de pedido

Enviar petición de oferta

Enviar RFQ con dibujos 2D/3D y requisitos detallados a través de correo electrónico o formulario en línea.

Revisión y presupuesto

Nuestro equipo de ingenieros revisará detenidamente cada plano y le proporcionará un presupuesto preciso en un plazo de 6 horas.

Confirmar pedido

Confirma el presupuesto, los detalles y el plazo de entrega, y luego firma el contrato.

Producción

Organizar el proceso de producción, iniciar la programación y el mecanizado.

Control de calidad

Estricto control de calidad durante la producción y la inspección final.

Embalaje y envío

Empaquete las piezas, coloque las etiquetas de identificación de las piezas y comience el envío.