Latches are one of the important mechanical components used to keep two parts fastened together. They have found their way into industries such as automotive and aerospace, furniture, and enclosures. There are many types of latches, each for a specific environment and performance requirement.

In this article, we discuss the main types of latches, their applications to materials and surface finish, and how precision CNC machining, milling, and turning can achieve accuracy and reliability for latches.

What is a Latch?

Latches are mechanical devices that hold two components together. These components do not move or open by accident. It is operated by a catch-and-lock design, which may be activated automatically or manually. Latches differ in design by function and application, such as bolt-style, compression types, or magnetic types.

Materials such as stainless steel, aluminum, and reinforced plastic assure long life. Corrosion resistance makes latches an important element for safety and functionality in any industrial system.

Why Choose CNC‐Machined Latches for Industrial Applications?

CNC-machined latches are unmatched by any other latches concerning precision, consistency, and large-scale industrial applications. Such latches are manufactured by computer numerical control. There is uniformity in size and tight tolerance. The strength and smooth operation under mechanical stress are their main advantages.

Industries such as automotive, aerospace, and electronics rely heavily on precision and reliability from CNC machining. In addition to that, designing customized shapes and sizes is also an option, so it is suitable for high-performance environments. CNC-machined latches are definitely the right choice.

Types of Latches

Latches can be classified depending on their applications. Common types would consist of indoor latches, outdoor latches, mechanical or magnetic latching, and visible or hidden latches. Each category is meant for a particular design and performance.

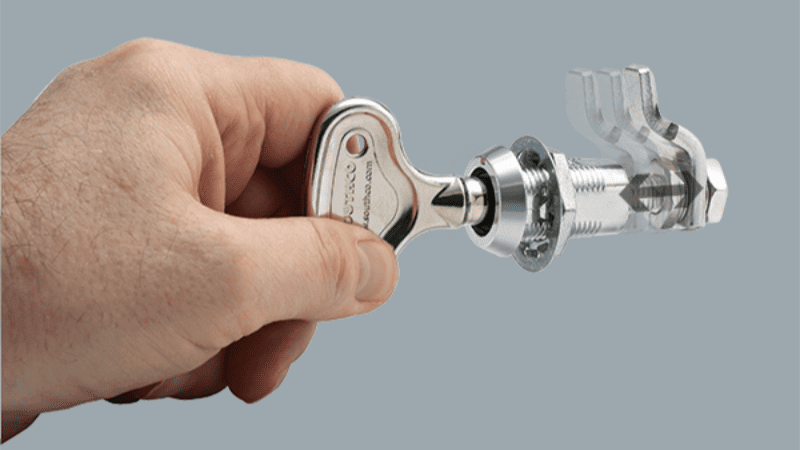

Cam Latches

Cam latches are simple rotating devices using a cam lever to lock doors or panels. They are commonly found on cabinets, electrical enclosures, and lockers where access is frequent. Their design allows the latches to be operated quickly while achieving a firm closure.

Cam latches are made of metal and plastic. It can also be sealed with keys or tools for additional security. Also, their ability to provide a solution that is easy to use effectively. Cam latches are one of the most versatile designs in both industrial and commercial applications.

Compression Latch

Compression latches guarantee a tight and vibration-resistant seal. They pull the door/panel tightly against the frame for excellent dust, moisture, and noise protection. These are best used in machinery compartments, marine equipment, and vehicles.

Compression latches are available in the adjustable and fixed-type versions, which add functional safety against inadvertent openings. They are preferred in industries where performance and environmental sealing are critical attributes. They ensure long-term stability and durability against continuous mechanical stress or temperature shifts.

Push-to-Close / Slam Latch

These are convenience latches, notwithstanding the design of slam locks being made for speed. Once the door is pushed to get it closed, the latch automatically engages without a manual lock. These are frequently used in latches for cabinets, toolboxes, and vehicle compartments while saving time in securing closure.

They are very durable, easy to install, and perfectly suitable for repetitive use applications. Either acero inoxidable or polymer in manufacture, push-to-close latches assure good performance and long service. They offer a very reliable solution for daily mechanical applications.

Draw Latch / Toggle Latch

Draw or toggle latches use a handle and latch action to bring two parts together under strong tension. They are ideal for securing covers, containers, and industrial cases that require a strong holding force. These latches come in various sizes and materials, are very strong, and adjustable.

Their mechanical advantage gives a tight closure and vibration resistance. Draw latches demonstrate their simplicity with the most robust performance. They render them perfect for heavy-duty and high-pressure fastening applications across shipping, automotive, and construction projects.

Sliding Latch / Bolt Latch

Sliding or bolt latches consist of a linear sliding bar locking a door or gate in a secure position. Their simple mechanism provides strength and reliability, making them ideal for gates, lockers, and access doors. Easy operation with installation in either surface mounts or flush mounts.

Fitted with a padlock, sliding latches provide a good measure of extra security. Made of corrosion-resistant materials such as stainless steel or brass. They withstand wear and help to provide lasting protection and an easy locking solution for a wide range of applications.

Spring Latch

Spring latch consists of an internal spring mechanism that releases and returns it to a latched position on an automatic basis. Primarily used in doors, cabinets, and particularly machinery covers. This activates a very fast and reliable engagement. Spring latches provide a single-handed operation for easy accessibility when a very frequent use takes place.

These latches are available in different tension strengths to ensure holding power while allowing easy release. Both compact structure and reliable functioning make spring latches exceptional for houses. These are for industries in which high efficiency and tight closure are required.

Hasps

Hasps contain a metal strap that is hinged, a staple to be secured by a padlock over a point. The simplest and effective locking system is extremely easy. The usual uses of such hasps are for toolboxes, storage units, and gates. So hasps are indeed durable and tamper-resistant.

Such designs allow easy installation with so many different sizes of locks. Stainless steel or coated hasps are available for non-weathering and non-corrosive long-lasting performance. Hasps are versatile and economical, which makes them an integral accessory across industries.

Swinging Latch

The swinging latch functions through a pivoting arm that locks itself into the keeper or strike plate. Most of the time, they are found in the gates, cabinets, and access doors that require the mechanical procedure. This swinging action opens quickly and closes fast.

They provide smooth operation and the necessary corrosion resistance possible are the offerings of these latches. It also comes in different metales and coatings. A combination of use and aesthetic appeal makes it highly recommended for use in modern installations.

Turn Latch

The turn latch more often uses a handle or knob rotating to turn and lock or release the lock. It is primarily used in controlled access into entry panels of electrical panels, furniture, and access covers. It can also be found in other objects. Rotating the turn action means it will give a good and comfortable grip for use.

They are available in quarter-turn or half-turn variations and ensure tight sealing with stability. Different materials can be used to manufacture turn latches. They are functional for industrial and decorative purposes.

Precision-engineered construction is the advantage of these turn latches. They ensure long-lasting durability and adaptability for many operational conditions and environmental situations.

Uses of Latches

Indoor Latches

Indoor latches are usually lightweight and designed for such applications as cabinets, furniture, and interior doors. They should be visually good-looking, user-friendly, and quiet-action, whereby materials such as zinc alloy or plastic can be used.

These latches come with comfortable handles or possibly some with hidden locking systems, helping preserve the indoor elegance. Indoor latches perform just that with reliable access and security. They are compromising on interior design and visual harmony, an accessory in office, residential, or equipment panel applications.

Outdoor Latches

Outdoor latches should protect against any of the elements. All of them would have to withstand rain, heat, or corrosion. These latches are typically made out of stainless steel, aluminum, or weatherproof alloys. They would ensure that they are strong enough to take some ruthless punishment.

Some other applications would include outdoor or field applications, such as gates, trailers, marine compartments, or even garden cabinets. This prevents rust due to their coatings and seals, while only a pressure-acting, mechanically designed one holds it tightly.

Most latches are equipped with locking mechanisms that increase protection. Outdoor latches, weighing strength and security against being crushed internally. They truly ensure long life and durability against any weather condition, particularly for exterior or exposed conditions.

Mechanical or Magnetic Latching

Mechanical and magnetic latches exist for specialized applications based on needs and requirements. Mechanical latches are those locks that work on physical parts for engagement, which are extremely strong and stable. Magnetic latches use the magnetic capacity for silent and smooth operation and are perfect for cleanrooms or electronic enclosures.

So each category will give specific advantages, mechanical for toughness and magnetic for fine-tuning. The industry usually chooses between either according to the operational environment accessibility. Its maintenance requirements are to ensure efficiency and safety in performance.

Visible or Hidden Latches

Visible latches are meant to be seen and are part of the appearance of the product in furniture and decorative installations. Hidden latches are part of the panel or frame for an immaculate aesthetic, as well as security. They offer tampering resistance and cleaner surfaces.

Choosing between visible and hidden latches depends on accessibility, security, and design preference. However, being functional, both are reliable for various visual requirements. It is common for hidden versions to be used in modern machinery and electronics. Visible ones are found in a majority of traditional architectural applications.

Finishing and Coating for Latches

Surface finishing and coating processes have a very important effect on the performance and durability of latches. They help protect the latch against corrosion, abrasion, and deterioration in the environment, while at the same time improving its aesthetic.

Tactile quality and friction during the operation will also be affected by finishing. Below are some of the common techniques used for latch finishing.

Polishing and Buffing

Polishing and buffing will create a better appearance and smooth surface in metal latches. The flaws will be removed, and a clean reflective finish will be obtained for aesthetic or hygienic use. Polished latches are now easier to clean and resist corrosion better.

The common application of buffing is for stainless steel or brass components, as it reduces friction and wear. Industrial manufacturers polish latches that are used in medical or food-grade equipment where surface quality is required. This finishing method is to ensure durability, functionality, and an appealing lustrous metallic nature.

Painting and Powder Coating

Strong protective layers against oxidation, rust, and chemical exposure are painted and powder-coated surfaces. These coatings add to the durability and color improvements, making the latches appear more professional.

Powder coating is the process that is commonly chosen for being environmentally friendly and not using solvents in its application. Both methods offer varieties in texture, gloss, and color customization. It contributes to making the products compatible with the aesthetics that the brand may want to portray.

Coated latches are also ideal for outdoor or marine conditions where there is continuous exposure. They not only protect. These also bring in better resistance for longer functional as well as visual consistency in the application share.

Metal-Plating

In metal-plating, a thin protective layer such as zinc, nickel, or chrome is applied to the latch surface. This gives it a strong corrosion resistance, as well as moisture and abrasion resistance. It also helps in the improvement of conductivity and enhancement of overall mechanical performance.

Chrome latches are famously known for shining like a mirror. The zinc plating provides an economically convenient protection solution. Industries commonly use metal-plated latches where there are extreme conditions or moisture, as this is the most important for endurance.

The plating guarantees enhanced surface quality and prolongs service life without affecting performance and external looks over time.

How to Choose the Right Latch for Your Application

Among the factors to consider when choosing a latch are the environmental settings, materials, locking strength, and frequency of use. This factor checks whether the latch would face vibration, weather, or heavy mechanical loads, among other criteria.

Size, mounting style, and access needs are some other examples under consideration. CNC-machined metal latches are useful for designated assembly lines. Industries with CNC machines use them for their precision and durability features.

Indoor or decorative applications may use plastic or hidden latches, especially in the absence of easy maintenance. Considering ease of maintenance, durability, and finish quality helps provide reliable performance. Match functionality with application requirements for the best latch choice.

High Quality Custom Latches from DEK

DEK focuses on accuracy, custom latches built for strength, accuracy, and efficiency. We also provide custom latch designs for industrial and commercial use. Our products undergo demanding testing to meet performance standards.

For excellent strength and corrosion resistance, DEK is the trusted choice. Póngase en contacto con nosotros today to discuss your latch design requirements and experience quality in custom-manufactured industrial components.

Conclusión

Latches may seem simple, yet they play an important role in security, stability, and accessibility across different applications. By understanding different types and finishes, most users can make choices for their operational needs.