- Inicio

- Prototipos de automoción

Prototipos de automoción Servicios

DEK has extensive experience in automotive prototyping and custom auto parts manufacturing, including manufacturing for world-renowned automotive companies such as BMW, Lamborghini, Land Rover, Toyota and Volkswagen. Whether it's from proof-of-concept to engineering testing of mechanical components, interior part manufacturing to exterior lighting prototypes, we provide expert technical support to produce high-performance physical prototypes and automotive parts.

- Precios competitivos

- Productos para la producción

- Asistencia técnica 24/7

- Launch Products Faster

- Certificación ISO 9001: 2015

Prototipo de automóvil Servicios

DEK is the world's leading manufacturer of automotive prototypes and custom automotive parts, and since our inception, we have been committed to maintaining low cost and high quality output using advanced technologies. Our automotive manufacturing services include CNC machining, vacuum casting, rapid tooling, 3D printing, die casting and sheet metal fabrication.

With access to over 50 certified materials and professional experienced technical support, DEK excels in automotive prototyping, while also providing alta precisión (tolerances up to +/-0.005mm) customized automotive parts for your project with calidad constante y entrega rápida.

Our goal is to exceed our customers' expectations and help you succeed in the marketplace. DEK has no minimum order quantity and can save you an average of 40% cost by recommending the right process for your project. In addition to surface finishes options, we can also provide expedited service to meet urgent customer needs. Our strict adherence to ISO 9001 standards ensures that automotive prototypes and parts meet design requirements for size, performance and durability.

Auto Engine Part

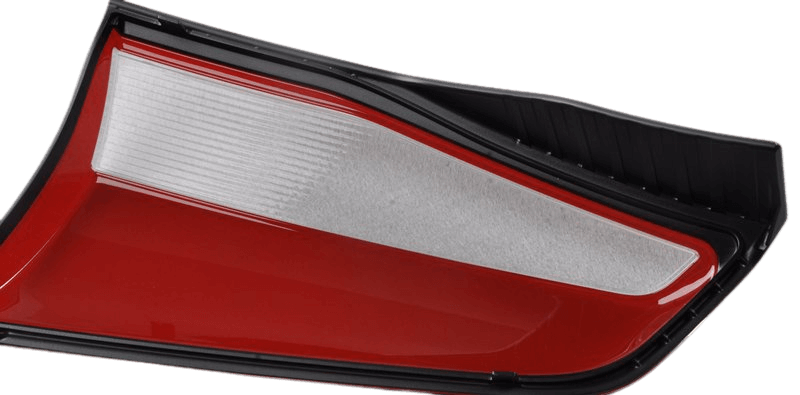

Reflector de faro

Parte estructural

Auto Starter Part

Car Body Part

Prototipos de automoción Capacidades

Mecanizado CNC

DEK has state-of-the-art CNC machining centers with 3-axis, 4-axis, 5 ejes for a wide range of metals and plastics, including aluminum, titanium, stainless steel, ABS, acrylic, nylon, and other product-grade materials.

Our engineering and production teams have the experience and design flexibility in automotive prototyping and component production to quickly produce physical prototypes of complex geometries and shorten development cycles. From automotive prototypes to low-volume manufacturing, DEK can provide you with cost-effective quotes based on market prices and quickly deliver high-precision and high-quality parts.

Fundición en vacío

DEK specializes in exterior prototype parts for automobiles made using vacuum casting methods, such as light housings and bumpers, as well as functional parts with complex internal structures, such as radiators and engine components.

We offer more than 50 types of certified materials and the flexibility to produce the automotive prototypes or parts you need to ensure that the end-use parts meet your project requirements. With our advanced equipment and proven vacuum casting technology, we can quickly manufacture complex shaped parts and test and verify the feasibility of the design before officially producing the part. Our prices are cost-effective for low-volume production.

Utillaje rápido

When multiple identical plastic prototypes need to be built, our rapid tooling services are your best solution. We use aluminum molds and silicone molds for manufacturing, allowing us to create small batches of prototypes for you, with a price advantage in terms of individual prototype cost.

Using a combination of rapid tooling and injection molding manufacturing methods, DEK is able to create hundreds of custom automotive parts, including bumpers, reflectors, light guides, bezels, exterior lenses, and other components for our customers in a much shorter period of time, allowing for flexible adjustments and modifications to meet the demands of rapid product development.

Fabricación de chapas metálicas

DEK provides high quality and reliable sheet metal fabrication services, capable of realizing complex shapes and precise dimensional requirements. We use proven sheet metal processes to manufacture prototype and customized parts for structural body parts that not only offer price advantages, but also ensure structural strength and stability.

We have a wide range of materials to choose from, mainly using lightweight materials, including aluminum alloys, HSS, UHSS, magnesium alloys, etc., to improve the performance of the vehicle as well as energy saving and environmental protection. In addition, we can provide a variety of surface treatments, such as painting, galvanizing, and polishing, to improve the corrosion resistance and aesthetics of auto components. Our efficient sheet metal technology enables high volume production and ensures consistency and quality of parts.

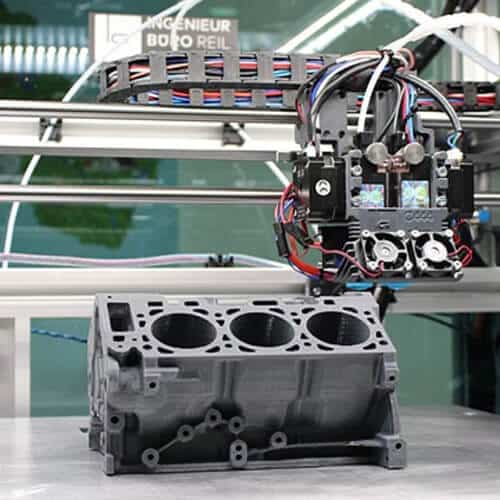

Impresión 3D

DEK's 3D printing services can help you quickly turn your automotive prototyping ideas into reality, shorten the development cycle, and help designers and engineers iterate and test quickly and make timely adjustments.

We can provide over 50 certified materials to meet different customer needs. We can realize complex geometries, reduce design constraints, and customize the automotive components you need. We simplify the production process with flexible manufacturing that is cost-effective in automotive prototyping and low-volume part production. Our talented engineering team provides fast, efficient and flexible solutions for automotive applications.

Materiales

Prototipo de automóvil Opciones de material

Aluminio

At DEK, we specialize in machining a variety of aluminum alloys including AL6061, AL5052, AL7075, AL5083, and AL2024, perfect for automotive prototypes and custom parts. Utilizing aluminum's light weight, strength, and corrosion resistance, we create high quality housings, cylinder heads, manifolds, ductwork, and bus ducts that meet your exact specifications.

Acero

At DEK, we specialize in machining all types of steel, including alloy steel, mild steel and stainless steel, ideal for automotive prototypes and custom parts. Utilizing the strength, durability, and corrosion resistance of steel, we produce high-quality brake components, engine components, chassis components, gears, exhaust systems, and suspension components to meet your exact specifications.

Titanio

At DEK, we specialize in machining all types of titanium, including Grade 1 titanium, Grade 2 titanium, and Grade 5 titanium, which is an excellent material for automotive prototypes and custom auto parts. Utilizing titanium's light weight, high temperature and corrosion resistance, we produce high precision fasteners, turbines and suspension components to meet your exacting requirements.

Nylon (PA)

At DEK, we specialize in nylon precision machining for automotive prototypes and custom parts. Nylon's strength, abrasion resistance and lightweight properties make it ideal for demanding automotive applications. Our advanced capabilities allow us to manufacture durable, high-quality automotive components such as engine peripherals, covers and housings.

Acrílico (PMMA)

At DEK, we specialize in the machining of Acrylic for automotive prototypes and custom auto parts. PMMA has excellent transparency, shatter resistance and lightweight properties, making it ideal for automotive lighting applications. We manufacture high-quality automotive clear components such as headlight housings, headlight lenses, dashboard lenses and taillight lenses on demand.

Silicona

At DEK, we specialize in silicone precision fabrication for automotive prototypes and custom parts. Silicone's flexibility, heat resistance and durability make it an excellent choice for automotive applications. We are a one-stop shop for high-quality seals, cover assemblies, fluid management devices and respiratory devices. Trust DEK for reliable, top-tier machining solutions.

Proceso

Our Manufacturing Proceso

Concept Prototype and CAD Digital Model

The automotive prototyping process begins with an initial presentation of design ideas based on market requirements using hand-drawn structural drawings, followed by the creation of a conceptual prototype using CAD (Computer Aided Design) software. Concepts are then brought to life using clay models to realize the idea of a real object, helping automotive designers to better evaluate and optimize the iterative process within the team, customers, and stakeholders to ensure both functionality and aesthetics before final production.

Structure and Function Verification

Automotive engineers refer to this phase as the “mule phase,” during which they build a series of functional prototypes, primarily to validate the spatial fit of components and collect functional data. This helps to assess structural dimensional reasonableness and ease of installation, and enables engineers to observe how prototype components work with the vehicle and other components, while examining design, materials, strength, tolerances, assembly, operating mechanisms and manufacturability, so that potential problems can be detected and solved in advance.

Engineering Testing and Pilot Production Run

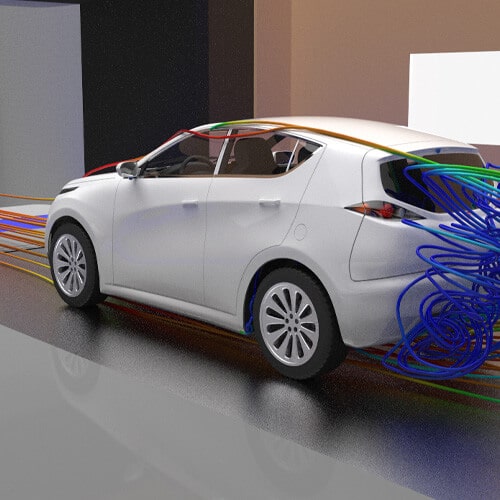

In order to ensure that automotive prototypes are truly equipped with a variety of useful features, they need to be tested for a number of things, including aerodynamics, ergonomics, mechanical properties, thermal properties, electrical properties, product longevity, and safety standards.

By testing prototypes in real-world conditions, engineers can quickly iterate based on feedback to meet the required performance, validation, certification and quality requirements. Prototypes loaded for component testing are tested in different scenarios and extreme conditions, enabling rapid identification of potential problems, such as those that prevent the product from functioning properly or pose a safety hazard. Small-volume manufacturing for pilot production can help identify vehicle production challenges and optimize the cost-effectiveness of manufacturing.

Por qué elegir Nuestros servicios

La producción única de prototipos de alta calidad le ahorra tiempo y dinero.

Capacidades de ingeniería

Producción rápida

Acabados superficiales

Control de calidad

Montaje de precisión

Embalaje y transporte

Nuestra Proceso de pedido

Enviar petición de oferta

Enviar RFQ con dibujos 2D/3D y requisitos detallados a través de correo electrónico o formulario en línea.

Revisión y presupuesto

Nuestro equipo de ingenieros revisará detenidamente cada plano y le proporcionará un presupuesto preciso en un plazo de 6 horas.

Confirmar pedido

Confirma el presupuesto, los detalles y el plazo de entrega, y luego firma el contrato.

Producción

Organizar el proceso de producción, iniciar la programación y el mecanizado.

Control de calidad

Estricto control de calidad durante la producción y la inspección final.

Embalaje y envío

Empaquete las piezas, coloque las etiquetas de identificación de las piezas y comience el envío.

Enviar RFQ 222

Revisión y presupuesto

Confirmar pedido

Producción

QC

Entrega

Automotive Prototyping Service Preguntas frecuentes

Obtenga un presupuesto exacto Para sus próximos proyectos

No importa que su proyecto sea complicado o sencillo, no importa que sea de metal o de plástico, obtendrá un presupuesto preciso en un plazo de 6 horas.

Pida presupuesto hoy mismoConocimientos of Automotive Prototyping

What is Automotive Prototyping?

Automotive prototyping entails creating the first sample (prototype) of a vehicle, part, component, or tool. Prototyping is one of the most vital steps between the initial sketch or design and the final product.

With the help of prototyping, manufacturers can check the functionality of a component, the proper materials, visualize its structure, check for errors, and, most importantly – test its safety.

If you want to know more about automotive prototyping, you can read la guía definitiva para la creación de prototipos de automoción aquí.

Advantages of Automotive Prototyping

Riesgo reducido: Automotive prototypes reduce the risk of mass production by identifying design and functional defects as early as possible.

Ahorro de costes: Resolver los problemas durante la fase de creación de prototipos garantiza un proceso de fabricación rentable.

Mejorar la calidad: Mediante pruebas iterativas y perfeccionamiento, la creación de prototipos garantiza que el producto final sea estéticamente agradable y funcional.

Comunicación mejorada: La creación de prototipos fomenta una mejor comprensión y coordinación entre los miembros del equipo y las partes interesadas.

Applications of Automotive Prototyping

Lighting Systems: Optical prototyping is used to test and evaluate the shape, optical clarity, heat dissipation, and weather resistance of headlights, taillights, fog lights, and lamp housings.

Interior Systems: Prototyping was used to evaluate button layout, tactility, display placement and visibility to ensure easy and safe access for the driver.

Body Systems: Body panel prototypes are used to test the aerodynamic performance, structural strength and visual appearance of vehicles.

Power System: Engine prototypes test the fit of various components, the efficiency of the cooling system, and vibration and noise levels.