Medical device housings require high dimensional accuracy, tight assembly tolerances, and flawless surface finishes to meet hygiene and functional demands. Material selection and sharp edge control further add to the machining complexity.

DEK employs multi-axis CNC milling with edge-breaking and fine deburring processes to achieve sharp geometry without burrs. We use validated process flows with traceable material lots to maintain dimensional stability and surface integrity.

Each housing is inspected for tight fits, surface quality, and material compliance using optical CMM, surface profilometers, and visual standards under ISO 13485 protocols.

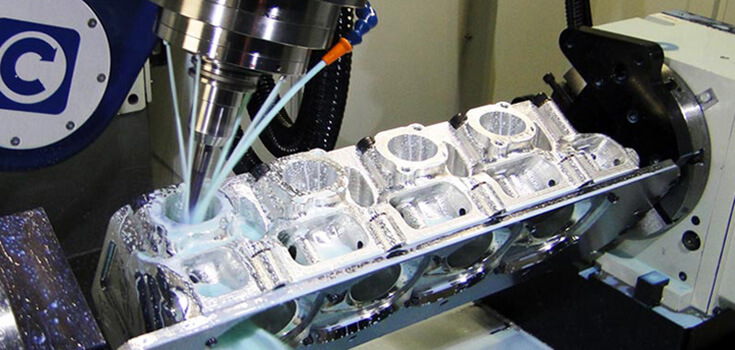

5-axis CNC milling ensures precise cutting of undercuts, internal ribs, and contoured shapes critical for ergonomic and functional housing design. This reduces setups and improves repeatability.

We apply Type II and Type III anodizing with RoHS and ISO 10993 compliance. Thickness is tightly controlled (±2μm) and traceable per part number and batch.

Edges are hand-finished with medical-grade tools. Controlled edge breaks (R0.2–R0.5mm) ensure safety in handling and reliable sealing in assembled products.

All aluminum, stainless steel, and titanium grades are sourced with full mill certs. Each housing is marked with batch info for traceability.

Hole alignment, flatness, and surface quality are verified with CMM, height gauges, and optical scopes.

DEK provides the precision, speed, and zero-defect manufacturing that mechanical engineers trust for their most critical applications.

Send us your drawing—we’ll provide fast DFM feedback and a precise quote, no minimum order.