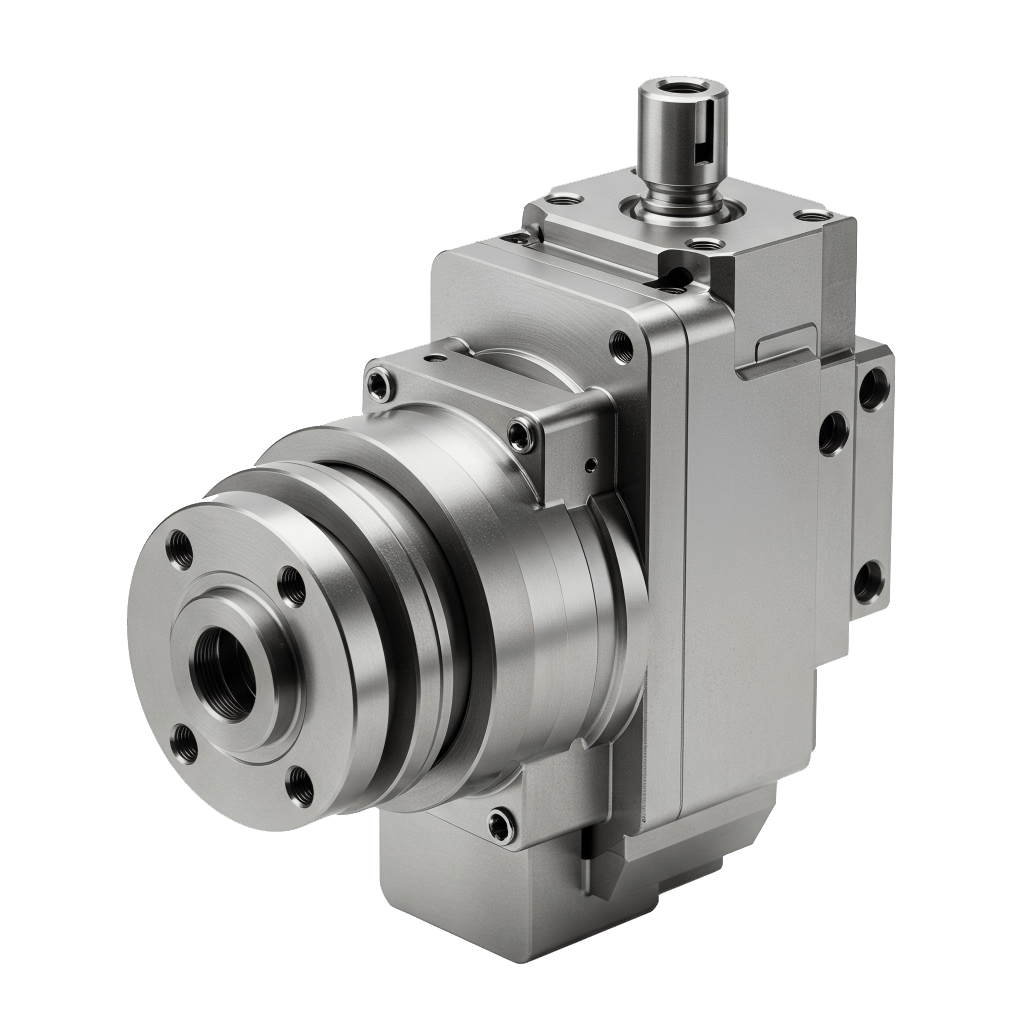

Actuator components often require tight fits, multiple thread sizes, fine flatness, and precise hole positioning. Thin walls and multi-face geometries increase machining complexity.

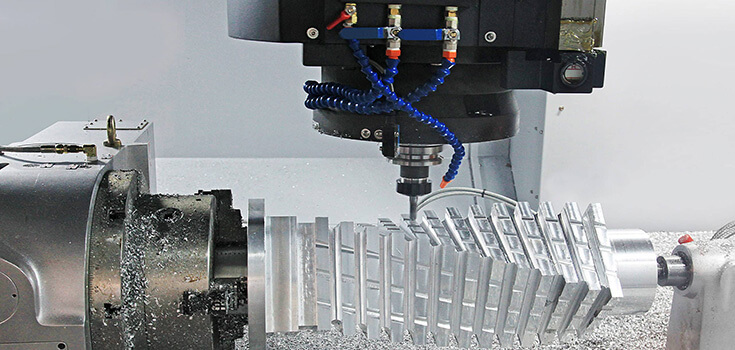

DEK applies 5-axis CNC milling for simultaneous surface and hole machining, minimizing re-clamping errors. Thread milling ensures clean internal threads with consistent pitch and depth.

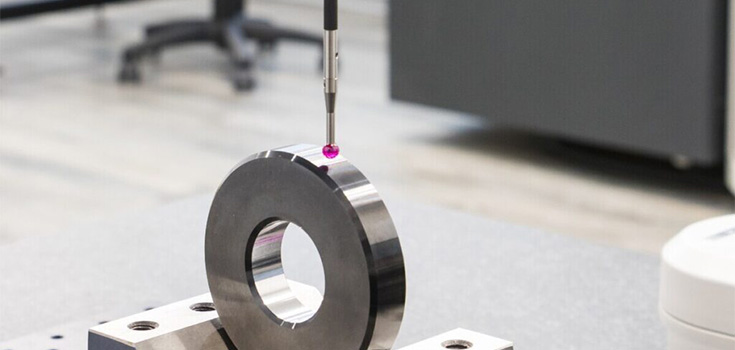

Surface treatments such as anodizing or zinc plating are applied per application needs. We control all critical tolerances through structured in-process checks and final CMM inspection.

Actuator parts with multiple intersecting holes or compound angles are milled in one setup using 5-axis machines. This eliminates misalignment between functional surfaces.

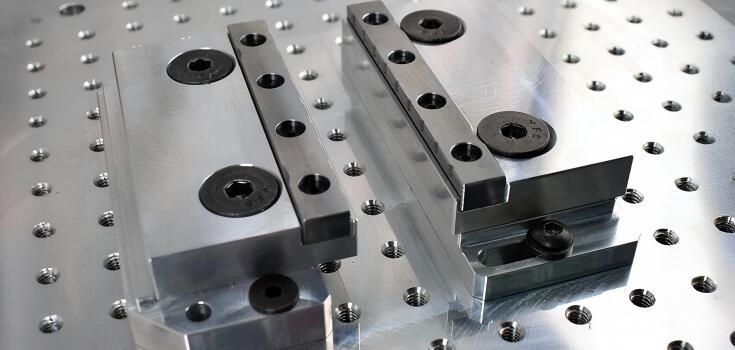

Threaded holes are machined using thread mills for consistent minor diameter. Each thread verified with calibrated gauges—blind holes deburred and cleaned.

For aluminum actuator bodies, Type II and Type III anodizing available. Steel parts zinc or nickel plated. Surface roughness checked with contact profilometer.

Milled surfaces controlled using lapping or surface grinding where needed. Flatness and parallelism inspected with dial indicators and granite surface plates.

We support both prototype units and batch runs up to 10,000 pcs. Fixturing designed to ensure consistency and reduce per-part cost in larger runs.

DEK provides the precision, speed, and zero-defect manufacturing that mechanical engineers trust for their most critical applications.

Upload your actuator part drawings for a fast, engineering-reviewed quote within 12 hours.