CNC machining bronze delivers high-precision components with outstanding strength, wear resistance, and corrosion protection. I often use it for parts that must perform under friction, pressure, or harsh conditions. Bronze’s natural lubricity and stability make it a reliable material for bearings, valves, and mechanical assemblies.

Each bronze alloy behaves differently during cutting. By adjusting tool geometry, feed rate, and cooling methods, I can achieve precise dimensions, smooth surfaces, and consistent quality across every CNC-machined bronze part.

What is Bronze Machining?

When I talk about bronze machining, I mean shaping and cutting bronze alloys into accurate parts using CNC machines. This process helps me create components with exact dimensions and fine surface finishes. Bronze is a strong, durable, and naturally resistant to corrosion, making it an excellent choice for mechanical, marine, and artistic applications. I usually use it for parts that need high wear resistance and stable performance over time.

Techniques for CNC Machining Bronze

Fresado CNC

I use this method to create slots, threads, pockets, and detailed contours. Fresado is a very flexible machining process for bronze that lets me work on several sides of a part with high accuracy.

Torneado CNC

En Torneado CNC, I rotate the bronze workpiece while the cutting tool moves in a straight line. This process is perfect for making round parts like shafts, pins, and bushings.

Perforación

I use drilling to make clean, round holes in bronze. The metal’s softness allows faster drilling, compared to harder alloys, but I still manage the speed and coolant carefully to avoid heat buildup.

Rectificado

It removes small amounts of material with precision and leaves a smooth, accurate surface. Since bronze is softer than steel, I take light passes and use plenty of coolant to avoid smearing or overheating the part.

Serrar

I use fine-tooth blades and steady feed rates to keep the cut edges clean. Slower speeds help prevent burrs and uneven surfaces. A good saw cut saves time in later machining stages and keeps the material waste low.

Brochado

This method allows me to cut internal shapes like keyways, splines, or other irregular profiles. Bronze’s ductility works well with the broaching process because it can handle pressure without cracking.

Mecanizado por descarga eléctrica (EDM)

This method removes material with controlled electrical sparks instead of physical cutting. EDM is especially useful when machining hard or delicate bronze parts that can’t handle too much force.

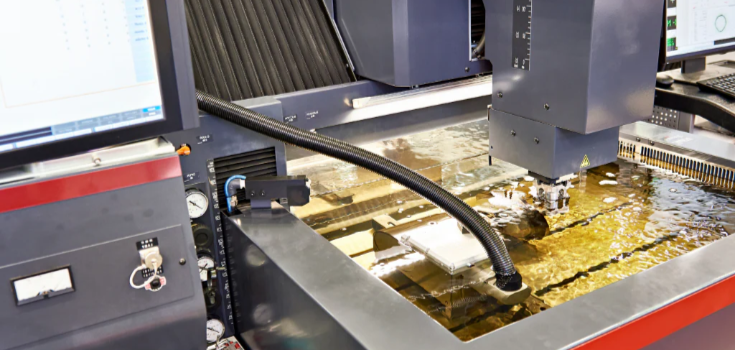

Waterjet Cutting

This method helps me shape thick bronze sheets quickly and cleanly. The high-pressure water mixed with abrasive cuts through bronze without heat, so there is no distortion or surface damage. I often use the waterjet cutting process to rough-cut parts before CNC milling or turning.

Types of Bronze Available for CNC Machining

Aluminum Bronze

It contains up to 12% aluminum, giving it high strength and great protection against seawater corrosion. I use aluminum bronze for bearings, gears, and valves that face friction and pressure every day.

Phosphor Bronze

Phosphor bronze is smooth, low-friction, long-lasting, and contains a small amount of phosphorus that increases hardness and fatigue strength. It is a great choice for electrical connectors, springs, and aerospace components.

Silicon Bronze

Silicon Bronze has about 2-3% silicon. It is strong, easy to cast, and works well for detailed or decorative pieces. I usually use it for marine or outdoor parts because of its strong protection against rust and environmental damage.

Manganese Bronze

This type includes zinc and other elements that boost strength and impact resistance. Manganese is my choice for heavy-duty applications like construction, automotive, or marine hardware because it can handle shock and stress while maintaining good wear performance.

Nickel Aluminum Bronze

It contains aluminum, iron, and nickel, making it one of the strongest bronze alloys. I usually use it for marine propellers, pump parts, and valves because it holds up well under friction and high loads.

Leaded Bronze

The added lead improves lubricity and chip control to help achieve smooth surfaces and fine details. It is a cost-effective material for moving parts like bearings, bushings, and sleeves.

Tin Bronze

It usually contains 2-8% tin, giving it good strength and excellent wear resistance. Tin bronze is one of the trusted bronze alloys, and I often machine it into gears, bushings, and bearings.

Bismuth Bronze

The bismuth helps with machinability and provides clean cuts. I often choose this alloy as an eco-friendly alternative to leaded bronze for projects that require lead-free materials, especially for parts used in food, water, or medical equipment.

Copper-Nickel Bronze

This type combines the conductivity of copper with the strength and rust protection of nickel. Copper-nickel is a good choice when making valves, fittings, and condenser components.

Bearing Bronze

It is designed to reduce friction and resist wear under constant movement. I machine it into bushings, thrust washers, and sleeve bearings.

Summary Table of Bronze Materials

| Bronze Type | Key Property | Common Use |

| Aluminum Bronze | Alta resistencia | Accesorios marinos |

| Phosphor Bronze | Resistencia al desgaste | Springs, electrical contacts |

| Silicon Bronze | Resistencia a la corrosión | Fijaciones |

| Manganese Bronze | Load-bearing | Gears, shafts |

| Nickel Aluminum Bronze | Seawater resistance | Propellers |

| Leaded Bronze | Easy to machine | Rodamientos |

| Tin Bronze | Duradero | Bujes |

| Bismuth Bronze | Lead-free | Eco applications |

| Copper-Nickel Bronze | Heat tolerance | Válvulas |

| Bearing Bronze | Baja fricción | Bearings, sleeves |

Surface Finishes Available for CNC Machined Bronze Parts

Acabado mecanizado

This is the natural look of bronze right after machining. You can still see the tool marks, but it is good enough for parts that don’t need to look perfect or have a super smooth surface.

Pulido

Polishing gives the bronze a bright, shiny finish. I do this when I want the part to look attractive, especially for visible or decorative applications. It also helps make the surface smoother.

Lijado

Sanding removes small scratches and imperfections from the surface. I choose different sandpaper grits depending on how smooth I want the finish. The finer the grit, the smoother the surface.

Cepillado

Brushing creates a soft, matte texture with fine lines. I often use this finish on architectural or decorative parts where I don’t want the surface to be too reflective.

Granallado

In bead blasting, tiny glass or ceramic beads hit the surface under pressure. This gives a uniform matte look and hides small tool marks. I like using this when I want a consistent, clean finish.

Chemical Coating

I use chemical coatings to protect bronze from corrosion and change its color. The coating forms a thin layer on the surface, giving both protection and an improved appearance.

Anodizado

This surface finish is not usually for bronze as it is for aluminum, but it can still be done on certain alloys. It helps improve corrosion resistance and allows me to add decorative color.

Patination

Patination uses chemicals to create a natural, aged look on the bronze. I use it when I want to achieve colors like brown, green, or blue. It is popular for art pieces and architectural designs.

Galvanoplastia

I apply electroplating to deposit a thin layer of metal, such as níquel, silvero gold. It protects the surface against corrosion while providing a clean yet decorative appearance.

Advantages of CNC Machining Bronze

From my experience, bronze is one of the best materials to work with in CNC machining.

- It is easy to machine.

- It holds up well against moisture and chemicals.

- Strong but flexible enough to handle shaping without cracking.

- Doesn’t overheat during machining because it conducts heat very well, keeping parts precise.

- Balanced strength and softness make it work perfectly for bearings, bushings, and parts that slide against each other.

Disadvantages of CNC Machining Bronze

Even though I enjoy machining bronze, I still face a few challenges when working with it.

- Higher material cost, as bronze is made from copper and tin. For large batches, I always consider how to calculate machining costs for CNC machines to stay within budget.

- Tool wear can be higher than expected, requiring more frequent replacements and downtime

- Its softer nature makes it difficult to hold very fine details and it needs to be used at a slower speed to avoid damage, adding time to manufacturing.

- It can generate more heat during cutting. I need to monitor temperatures carefully and use coolants to keep tools in good working condition.

Applications of CNC-Machined Bronze Parts

I often use bronze to make threaded components, taps, nuts, bolts, gears, bearings, electrical terminals, screws, and bushings. These parts are common in automotive and industrial equipment, where bronze reduces friction, supports heavy loads, and extends service life. It is also valued in aerospace for its fatigue strength and in marine systems for its strong resistance to saltwater corrosion.

Bronze’s versatility extends to medical, electronic, and architectural uses. It offers precision and biocompatibility for surgical tools, reliable conductivity for connectors and terminals, and long-lasting beauty for decorative fixtures and sculptures.

Best Practices for CNC Machining Bronze

- Choosing bronze grades that cut smoothly, like bearing bronze, helps reduce tool wear and machining time.

- Batch production improves material usage, minimizes scrap, and helps maintain consistent part quality.

- Using advanced CAM software to plan efficient cutting paths helps save time and extend tool life. Optimized paths reduce unnecessary movements and heat buildup.

- Avoiding overly deep pockets or complex curves, if possible, keeps production faster and more affordable without sacrificing performance.

- Partnering with an experienced CNC machining team ensures that issues are caught early. This helps avoid rework, material waste, and costly production delays.

Comparison Table of Bronze and Other Metals in CNC Machining

| Material | Maquinabilidad | Fuerza | Resistencia a la corrosión | Resistencia al desgaste | Coste |

| Bronce | Medio | Alta | Excelente | Excelente | Medio-Alto |

| Low-Carbon Steel | Easy | Alta | Feria | Alta | Bajo |

| Latón | Easy | Medio | Bien | Feria | Medio |

| Aluminio | Easy | Medio | Bien | Bajo | Bajo |

| Acero inoxidable | Duro | Muy alta | Excelente | Muy buena | Alta |

| Cobre | Difficult | Bajo | Excelente | Bajo | Medio |

Your Best Outsourcing Partner for CNC Machining Bronze

At DEK, I work with a team that knows bronze inside and out. We use the right tools, speeds, and inspections to make sure every part meets tight standards. Either for custom prototypes or full production runs, we will help you achieve accurate and consistent CNC-machined bronze components. Póngase en contacto con nosotros ¡hoy!

Conclusión

DEK values CNC machining bronze not only for precision but also for sustainability. Bronze can be recycled repeatedly without losing quality, making it a practical choice for modern manufacturing.

Preguntas frecuentes

Is Bronze Difficult to Machine?

Bronze is not usually hard to machine, but the difficulty can vary by alloy. Softer grades like phosphor bronze and silicon bronze are easier to cut, while aluminum bronze is tougher due to its high strength.

Which Bronze Alloys Are Easiest to Machine?

Leaded bronze and Bismuth bronze are the easiest to machine. They provide great chip control and smooth cutting; bismuth bronze is also a great eco-friendly alternative for lead-free applications.

Is Bronze More Machinable than Brass?

Yes, bronze is generally easier to machine than brass. Its flexible composition and lower zinc content make it more stable during cutting. Bronze is mainly made from copper and tin, while brass contains copper and zinc. The higher zinc levels in brass can make it more brittle.

What are the Top Grades of Bronze for CNC Machining?

If you are machining bronze, go for grades like C954 aluminum bronze, C630 nickel aluminum bronze, or C863 leaded tin bronze. They handle cutting well and resist wear and corrosion. C954 aluminum bronze is the most preferred choice because it is strong yet still easy to work with.