Welding is an important process in making and fixing things. A strong weld keeps a structure safe and lasting. But welding defects can make a joint weak, shorten its life, and cause expensive repairs or failure.

Knowing the 15 common types of welding defects, why they happen, and how to stop them will help you make better welds and avoid problems.

What is a Weld Defect?

Welding defects are mistakes or flaws in a welded joint that can make it weaker or less visually appealing. Some defects can make the weld unsafe and unusable, while others may only affect how it looks.

How many types of welding defects are there? Well, welding defects can happen in different sizes and shapes, depending on the type of metal and welding method used. There are 15 common welding defects. The most common reasons for these are using the wrong welding technique or making mistakes in the welding pattern.

These defects can appear on the surface or inside the metal. Some only affect the appearance, while others can make the joint weak and unsafe. If the defects are too serious, the welded part may be rejected. That’s why preventing weld failure is important.

Harms of Welding Defects

Welding mistakes can be dangerous both when making and using a product. Here’s why:

- They weaken the structure, which can cause parts, machines, or buildings to break.

- Fixing or replacing faulty parts costs more money.

- Poor welds make products wear out faster, leading to higher maintenance costs.

- Cracks in welds can let harmful materials leak from pipes or machines, creating safety risks.

External Welding Defects

External welding defects are problems in the weld that you can see with your eyes.

Cracks

Cracks are serious defects that can grow over time and cause the weld to fail. They can appear in different ways: longitudinal cracks run along the weld, transverse cracks go across it, and crater cracks appear at the end of the weld.

Cracks can also form at different temperatures—hot cracks happen when the metal goes too hot and cools too fast, while cold cracks appear hours or days after cooling.

Causes:

- Using hydrogen shielding gas on ferrous metals.

- Applying too much stress to the metal.

- Joints that are too rigid and can’t expand or contract.

- High levels of sulfur and carbon in the metal.

Prevention:

- Preheat the metal and let it cool slowly.

- Maintain proper joint gaps.

- Use the right welding materials.

Undercut

Undercut is when the edges of the weld melt but don’t get enough filler metal, leaving weak notches along the joint.

Causes:

- High arc voltage.

- High travel speed.

- Wrong electrode or electrode angle.

Prevention:

- Use a shorter arc length and lower voltage.

- Hold the electrode at a 30-45 degree angle.

- Reduce electrode diameter.

Porosidad

Porosity happens when gas bubbles get trapped inside the weld, creating holes that weaken the structure and make it easier for contaminants to enter.

Causes:

- Dirty welding surface.

- Wrong electrode choice.

- Incorrect or missing shielding gas.

- Damaged shielding gas cylinder.

- Welding current too high or too low.

- Traveling too fast.

Prevention:

- Clean the surface before welding.

- Use the right electrode and shielding gas.

- Preheat the metal.

- Check for gas leaks or moisture contamination.

- Adjust welding current and speed.

Burn-Through

Burn-through occurs when the weld melts all the way through the metal, creating a hole in the workpiece.

Cause:

- Welding current too high.

- Gap too wide.

- Not enough root face metal.

Prevention:

- Keep a proper root gap.

- Control welding current.

- In some cases, you can remove the hole and re-weld.

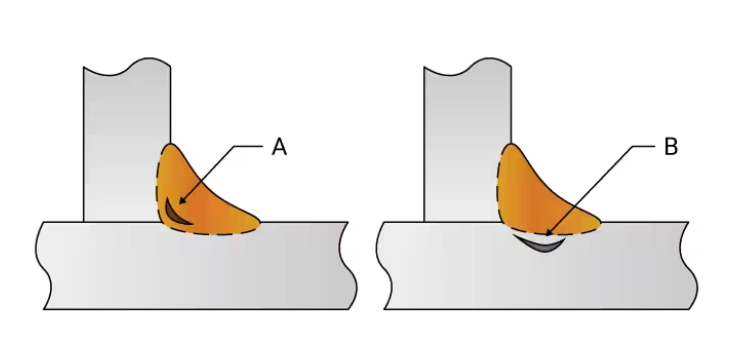

Overlap

Overlap happens when extra molten metal spreads beyond the weld but does not mix with the base metal, creating weak points.

Causes:

- Incorrect welding method.

- Wrong welding materials.

- Poorly prepared base metals.

Prevention:

- Use a smaller welding current.

- Apply proper welding techniques.

- Use a shorter welding electrode.

Under-filled

Underfilled happens when there isn’t enough weld metal, leaving a shallow joint that reduces the strength of the weld.

Causes:

- Low welding current.

- Traveling too fast.

- Making each weld layer too thin when doing multiple weld passes.

- Incorrect weld bead placement.

Prevention:

- Use the right electrode size and current setting.

- Avoid moving too fast.

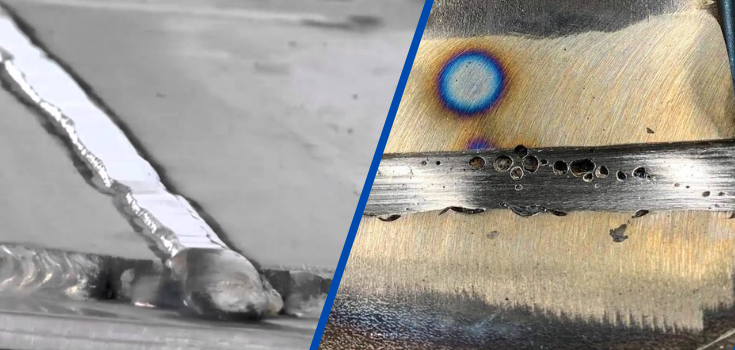

Spatter

Spatter is when tiny metal droplets scatter around the weld and stick to the surface. It doesn’t always weaken the weld but makes cleanup harder.

Causes:

- High welding current.

- High arc length.

- Poor shielding of the weld.

- Wrong polarity.

Prevention:

- Use the correct weld polarity.

- Choose the right shielding gas.

- Reduce welding current and arc length.

Mechanical Damage

Mechanical damage includes dents, scratches, or marks on the weld that happen due to mishandling or poor welding techniques.

Causes:

- Applying too much external force.

- Improper use of welding equipment.

- Not starting the arc before beginning to weld.

Prevention:

- Handle welding equipment safely.

- Engage the arc properly before starting to weld.

Distortion

Distortion, also called warping, occurs when the shape of the metal changes because of too much heat during soldadura.

Causes:

- Incompatible base and weld metals.

- Thin weld metal.

- Too many weld passes.

Prevention:

- Use the right weld metals.

- Reduce the number of weld passes.

- Choose the best welding method for the material.

Misalignment

Misalignment happens when metals are not positioned correctly before or during welding, leading to a weak weld, especially in pipes.

Causes:

- Welding too quickly.

- Poor metal alignment.

- Lack of welding skills.

Prevention:

- Use a slower, more stable welding process.

- Secure metals firmly before welding.

- Check alignment regularly and use the right techniques.

Internal Welding Defects

Some welding problems can’t be seen just by looking. These hidden issues are called internal welding defects.

Incomplete Fusion

This happens when the metals don’t melt and bond properly, leaving gaps in the weld. If the base metal and the filler metal don’t mix well, fusion won’t happen.

Causes:

- Not using enough heat, so the metal doesn’t melt fully.

- Holding the torch at the wrong angle or using the wrong welding position.

- Making the weld pool too big.

Prevention:

- Use a higher welding current and move slower to ensure proper melting.

- Adjust your welding positions, like the joint angle, torch angle, and bead position.

- Lower the deposition rate to avoid excess material buildup.

Slag Inclusion

If your weld has bits of slag trapped inside, it weakens the metal. Slag can get stuck on the surface or between layers when you weld. This happens most often with welding methods that use flux, like stick welding, flux-cored welding, submerged arc welding, and brazing.

Causes:

- Holding the welding torch at the wrong angle or moving too fast.

- Not cleaning the metal properly before welding.

- Using low welding current, which doesn’t heat the metal enough.

Prevention:

- Use a higher welding current.

- Keep the right torch angle and travel to prevent slag from getting trapped.

- Clean the weld area and remove slag between layers.

Incomplete Penetration

This problem happens most often in butt welding. It means the metal doesn’t melt all the way through the joint, so one side isn’t fully fused at the root.

Causes:

- Using the wrong welding technique.

- Choosing the wrong electrode size.

- Not applying enough filler material.

Prevention:

- Use the correct welding method.

- Increase the amount of filler material.

- Select the right electrode size for the job.

Other Welding Defects

Necklace Cracking

Necklace cracking is a problem in electron beam welding. It happens when the molten metal does not fill the cavity properly, leaving gaps.

Causes:

- Using metals like stainless steel, carbon steel, tin, or nickel-based alloys.

- Poor welding technique.

- Welding too fast.

Prevention:

- Choose better materials for electron beam welding.

- Keep a steady welding speed.

- Use the correct welding method.

Whiskers

Whiskers are a problem in MIG welding. They happen when small pieces of the electrode wire remain on the root side of the weld.

Causes:

- The electrode is placed too far ahead of the weld puddle.

- The wire feeds too fast into the MIG torch.

- Welding too quickly.

Prevention:

- Cut off the small piece of wire before starting.

- Reduce the wire feed speed.

- Slow down welding or use a different technique, like whipping the electrode.

How to Detect Welding Defects

Testing is a good way to check if a weld meets the right standards. It helps you find out why defects happen and how to fix them. Even though it takes time, testing makes sure the welds are strong and safe

There are two main ways to check for welding defects:

Destructive Testing

Destructive testing checks how strong a weld is by pushing it to its limit until it fails. Sometimes, you need both non-destructive and destructive testing to reduce defects. Some common destructive tests include:

- Acid etching

- Guided bend test

- Free bend test

- Back bend test

- Nick break test

- Tensile strength test

Non-destructive Testing

Non-destructive testing lets you check for problems in a weld without causing any damage. This is useful when you need to test samples from a batch without ruining them. Common NDT methods include:

- Visual inspection

- Liquid penetrants

- Magnetic particle testing

- Eddy currents

- Ultrasonic testing

- Acoustic emissions

- Radiography (X-ray testing)

Difference Between a Weld Discontinuity and a Defect

According to ISO 6520, serious defects are called “weld defects,” while minor ones that don’t affect strength are called “weld discontinuities.” The acceptable limits for these are set by ISO 5817 and 10042.

Conclusión

Welding defects can be dangerous and costly to fix. However, ensuring high-quality welds is always worth the effort. That’s why it’s important for you to understand the basics of welding and how to prevent defects.

With modern technology, welding has become more efficient. Advanced testing methods help you find and fix defects more easily. By improving both your welding skills and the equipment you use, you can greatly reduce defects and create stronger, more reliable welds. This is why industries today produce better-quality products than ever before.

En DEK, we provide top-tier welding solutions and testing services to ensure your welds meet the highest standards. Contact us today to learn how we can help you achieve flawless welds!

Preguntas frecuentes

What are the most common visual welding defects?

The most common welding defects you might notice are cracks, slag inclusions, porosity, undercut, spatter, and overlap. These issues can make the weld weaker and less reliable if they aren’t fixed properly.

What is the most severe welding defect?

Cracks are the most serious welding defect because they can make the structure weak and cause it to fail. If you find cracks, you need to fix them right away, usually by rewelding, since they can’t be left in the final product.