3D printing has turned a new beginning in manufacturing and prototyping. It authorizes easy, fast production of designs with extremely complex shapes. Using unsuitable 3D printing materials has led to technical problems, wasted resources, and safety risks. It can confirm successful conclusions and offer protection against wasting resources.

In this blog, you will learn about what materials cannot be used in 3D printing, why they fail, and learn about the relevant options for your projects.

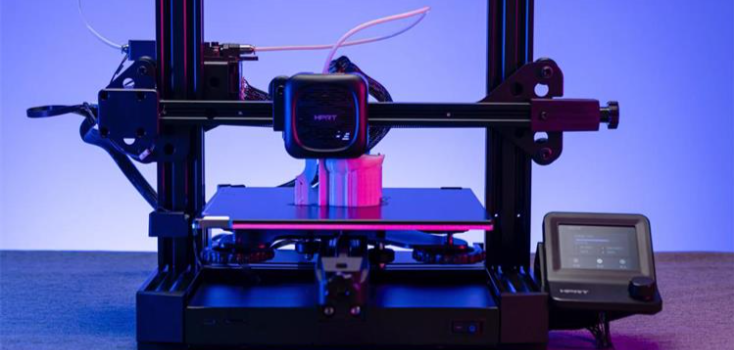

What is 3D Printing and How Does it Work?

3D printing, or additive manufacturing, is a way to build objects by adding material layer by layer, under the control of a computer-aided design (CAD) file. The process involves the deposition of material based on the model, instead of the cutting or shaping of raw material.

There are several techniques, such as FDM (fused deposition modeling), SLA (stereolithography), and SLS (selective laser sintering). These methods use various materials, but they are all based on the same idea of laying down thin layers on top of each other. This gives the advantages of fast prototyping and highly customized production.

What Materials Can Be Used in 3D Printing?

There are numerous possible materials for 3D printing, each one with its own properties. The materials you choose depend on the printer type and the intended use of the final product.

| Tipo de material | Examples | Aplicações comuns |

| Thermoplastics | PLA, ABS, PETG | Prototyping, models, low-cost parts |

| Resins | Standard resin, tough resin | Dental models, jewelry, functional parts |

| Metais | Stainless steel, titanium | Aerospace, automotive, medical implants |

| Compósitos | Carbon fiber-filled, wood-filled | Lightweight, strong prototypes |

What Materials Cannot Be Used in 3D Printing?

High-Melting-Point Metals

In most cases, tungsten, tantalum, and molybdenum cannot be printed with their own standard machines because their melting points reach above 3,000°C, far higher than what any regular printer can survive.

If you attempt to print these metals, you will face issues such as cracking, oxidation, and loss of energy. Better still, CNC machining can be chosen for those metals. Using accurate cutting and shaping processes instead of extreme temperatures.

Reactive Chemicals

Magnesium, sodium, and lithium are unsuitable materials because their highly reactive nature causes them to ignite, burst, or release harmful gases when heated by uncontrolled conditions during printing. This is risky, jeopardizing the safety of the operation crew.

Such elements would be more securely and reliably managed by controlled chemical processes or specialized industrial methods designed for such types of projects.

Non-Thermoplastics

As a general rule, 3D printing works well for thermoplastics, which soften under heat and harden when cooled. Non-thermoplastics such as epoxies, polyester, or silicone do not behave this way. Instead of melting, they burn or reduce under heat, leading to failed prints.

The most recommended techniques of processing these materials are molding, casting or curing chemically. Actually, inappropriate for extrusion or laser sintering.

Certain Plastics

Certain plastics cannot be printed safely or effectively. Examples include:

PVC (Polyvinyl Chloride): highly toxic chlorine gas is released.

Polystyrene: has poor bonding and is brittle.

Policarbonato: requires special machinery to avoid warping.

These weaknesses make them not very good candidates for 3D printing that would be reliable. For such cases, injection molding or other plastic forming techniques work best.

Glass and Ceramics

Most of the glass and normal ceramic stuff would require high melting points and slow cooling to avoid cracking. The common 3D printers could not have controlled the precision over heat and cooling. However, the print usually fails and produces weak and uneven parts.

Traditional methods of casting or machining are still the best methods available for glass and ceramic applications.

Composite and Fiber-Reinforced Materials

Carbon-fiber composites or fiberglass composites fail to make a good print as they clog the printer's nozzle and lack even bonding. Some fibers may break during manufacturing, leaving some weak points within the structure.

Hybrid printing processes are facing much development. Most composites remain difficult for standard 3D printing. Instead, 3D printing combined with machining is still a more efficient way to achieve better results.

Biohazard or Toxic Materials

Lead alloys, mercury compounds, or hazardous medical plastics have been proven unsafe for an open-environment printer. Printing with those can produce dangerous fumes or expose the operator to toxic particles.

These cannot be used in consumer or industrial printers without such stringent containment. There are many better alternatives, such as certified medical-grade polymers or controlled injection molding.

Unstable or Low-Strength Materials

Weak materials that readily deform while printing, such as wax, foam, and brittle thermoplastics, simply collapse during the process. They cannot cater for the weight of the layers being erected, resulting in either distorted or failed parts. Alternatively, you could have temporary models using resins or nylon powders, which are much stable but less hassle.

Why High-Temperature Metals Are Unprintable?

Materials like lead alloys, mercury compounds, or medical plastics, including dangerous chemicals, are unsafe for open-environment printers. Printing these may discharge dangerous gases or expose technicians to toxic fragments.

They also oxidize when open to air at high temperatures, weakening the final product. Finally, the cost of the machinery needed makes the process uneconomical compared to CNC machining.

What Plastics Are Unsuitable for 3D Printing?

Plastics that discharge toxic fumes, reduce too much, or crack under stress are unfit. PVC destroys the machinery and damages health. Polypropylene bends during cooling, making parts useless. Polystyrene is breakable and breaks under minimal force.

Fluoropolymers like PTFE break down under heat, creating risky fumes. Instead of forcing these plastics into Impressão 3D, you should depend on more secure materials like PLA, ABS, or PETG.

How Does Material Selection Depend on Printer Type?

The choice of materials is affected heavily by printer technology:

FDM Printers: Best for thermoplastics like PLA, ABS, and PETG.

SLA Printers: Use liquid polymers that are set under UV light.

SLS Printers: Work with powders, for example, nylon and composites.

Metal Printers: Limited to certain alloys consistent with laser fusing.

Understanding your printer’s design confirms that you choose materials that perform well and decrease print failures.

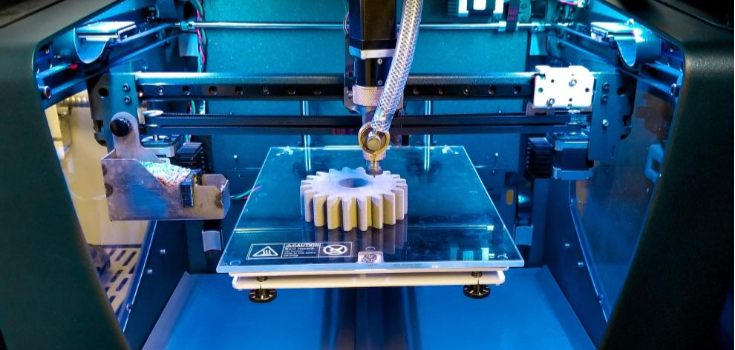

Applications and Materials for Everyday 3D Printing

This is a standard, reliable tool for consumer, industrial, and artistic applications of 3D printing. In the relief of your home, you can print prototypes, replacement parts, or decorative items using either PLA or ABS. Companies use polymer for producing jewelry, dental models, and engineering prototypes.

Materials like nylon and TPU enable functionality and flexibility for making parts like gears or usable products. Metals like stainless steel and aluminum are widely implemented in industrial-grade machines, making strong products for aerospace and automotive. These applications highlight how selecting the right material is key to success.

Can You 3D Print with Silicone?

Normal 3D printers cannot process silicone because it is not a thermoplastic. It does not melt during heating. Advanced techniques like liquid deposition modeling allow the printing of silicone-like materials.

These techniques are complex and need specialized equipment. They make it possible to produce flexible components such as seals, medical devices, and custom molds. For most users, TPU or flexible polymers would be an alternative. It affords similar advantages while being easier to process.

Conclusão

Not all materials are compatible with 3D printing, but that does not limit your modeling possibilities. By understanding which materials fail and why, you can select safer and more efficient options. This confirms predictable performance and decreases useless resources.

At DEK, we specialize in custom manufacturing solutions. Our experts understand your design, suggest the right materials, and give advanced machining services. If you need 3D printing, CNC machining, or hybrid solutions, DEK confirms your projects are completed with precision and efficiency. Contactar-nos e obter um orçamento gratuito.