One of the modern machining processes that gained attention over the years is helical milling. Whether you are a machinist, an engineer, or someone who is curious about the process, helical milling offers an interesting peek into modern manufacturing processes that are shaping our world today.

In this article, we will discuss interesting facts about helical milling. From the technical factors down to the best practices. We will give you a glimpse of this popular machining process.

What is Helical Milling?

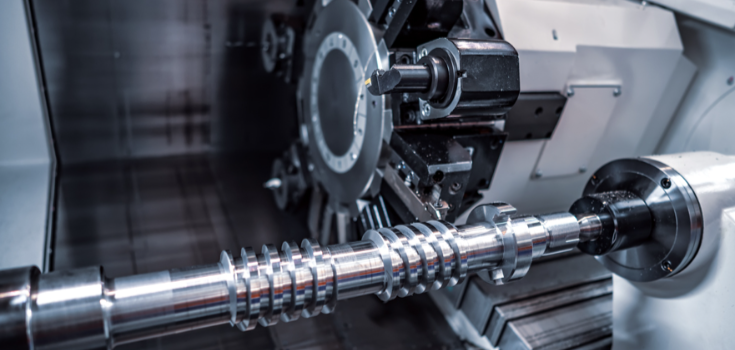

Helical milling is an efficient machining process that uses a milling tool that moves in a spiral path. This movement allows the tool to cut both axially and radially. This process is used for creating high-precision holes, particularly on tough materials like titanium and steel.

This process combines accuracy and tool life because it reduces force, which minimizes tool damage.

Technical Factors of Helical Milling

Helical milling, being a modern machining process, may look simple and easy to understand, but its efficiency relies on several technical factors.

Understanding these factors will help us gauge helical milling’s performance, especially on extremely hard surfaces that will test its tools' tolerance.

Toolpath Generation

Toolpath generation is one of the most crucial technical factors of helical milling because this refers to the programming of the milling tool to operate according to a designed path into a workpiece.

CAM (Computer-Aided Manufacturing) software is used to make the toolpath. The toolpath will define the tool’s capability to cut the material in a specific direction and gauge its tool engagement.

Seleção de ferramentas

Helical milling’s optimum performance lies in the tools chosen to be used in the process. It is generally useful to consider three factors in choosing the tool: the type, diameter, and design.

Specialized cutters are chosen to match the hard workpiece and surfaces. That is why strong materials are strongly preferred to ensure strength and stress tolerance.

It is usually recommended that the tool diameter is greater than the milling diameter and the workpiece's helical radius by approximately 40-60%.

The preference in the flute design depends on some considerations. Multiple flutes if you want smoother cutting and surface finishes, and fewer flutes for deep holes to improve chip evacuation.

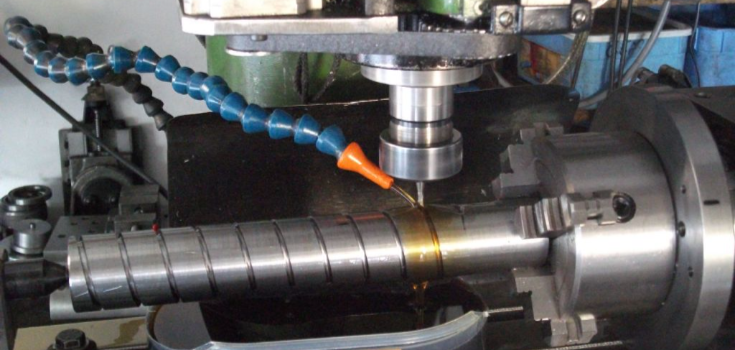

Chip Evacuation and Cooling

Heat control and chip removal are two important factors to ensure the smooth run of helical milling. An effective chip removal technique is needed because helical milling can produce piles of spiral chips that can clog deep holes and may cause tool damage.

Ensuring that the tool maintains a cool temperature is highly important because it reduces the stress on the tool.

Coolants and air blasts are needed to prolong tool life and ensure a smooth surface finish on every material.

Parâmetros de corte

The effective execution of helical milling also lies in the cutting parameters. These factors can significantly impact the result and the efficiency of the process.

O spindle speed, feed rate, axial depth, and helix angle must be carefully balanced to ensure efficiency and quality results.

Helical Milling Benefits

Helical milling is a modern hole-making process that delivers precision and quality results. Below is a rundown of the benefits of the highly popular machining process used by many industries today.

High-quality Holes

The gradual spiral motion of the tool used in helical milling is a huge contributing factor to the quality of the holes it produces, resulting in smooth finishes, superior quality holes, and uniform results in terms of diameters. This approach avoids common issues in the material and also the tool used for the process.

Hole Sizes Versatility

The one thing that sets helical milling apart from traditional drilling is that it has the capability to produce holes in different sizes using just one tool.

The trick is done by making adjustments to the radius of the hole and not to the tool itself. This benefit saves you more time because there is no need to change tools just to achieve a desired result.

Materials Flexibility

Helical milling’s ability to cut through even the hardest material is proof that it is an effective process that took traditional drilling to a whole new level. Helical milling works even on the most challenging materials, like hardened steel and titanium, without the risk of excessive stress on the tool.

The balanced force and heat make the process reliable for the tough materials that are commonly used in the medical and aeroespacial industries.

Lower Cutting Forces

Helical reduces the stress on the machine, the tool, and the surface itself. The gradual and evenly distributed cutting makes it an effective technique to use on hard materials and even on delicate surfaces.

Longer Tool Life

The balanced heat and forces used for this process ensure a longer life for the tool since it will not be exposed to excessive stress and overheating. The gradual approach to drilling will also not cause damage to the cutters. And the best part is that longer tool life means lower operational costs.

Helical milling is helpful and effective for industries that use hard materials like steel and titanium.

Efficiency on Chip Control

An efficient chip removal is essential in milling, not just to ensure a smooth finish but to save time on trying to unclog holes filled with chips that may even affect the final result.

Helical milling offers effective chip removal because of the tool’s spiral motion and with the use of an air blast while cutting.

Balanced Machining Temperature

Thanks to helical milling’s lower heat dispersion, incidents of overheating the tool can be avoided. Hence, the tool and the workpiece are safe from any damage.

Helical Milling Uses

Peças para automóveis

O automotive industry requires consistency. Manufacturing of automotive parts and components requires high-tolerance holes and cavities that helical milling can produce.

Helical milling’s capability to deliver consistent machining of holes and pockets using fewer tools also makes it capable of working on high-volume production.

Dispositivos médicos

With the medical industry’s need to have precise and burr-free holes for their medical devices, helical milling’s efficiency is the top-notch choice. From implants to stainless steel surgical tools, the intricate process of helical milling is helpful for their industry’s demands.

Aeroespacial

This industry’s demand for high-standard components and their use of hard steel and titanium is because to their standard of material integrity. That’s where helical milling’s expertise comes in.

Helical milling can also handle complex demands based on the critical safety standards of the industry.

Fresagem de roscas

Helical milling is being used for thread milling due to its capability to produce holes that meet their high-standard criteria for making valves and engine parts.

Plus, helical milling’s flexibility in working with challenging materials.

Mold Making

Molds have deep cavities and contours. Helical milling can keep up with the deep, intricate details of materials that are needed in this industry.

Manufacturing and Prototyping

The manufacturing industry demands flexibility and efficiency even in mass production. The ability to produce without frequent tool changes is helpful in production without sacrificing quality.

Energia

The energy industry’s demand for pipeline fittings and valves. These parts need to withstand harsh conditions and high pressure. And that’s where they can use helical milling’s advantage in terms of dealing with challenging materials.

Challenges and Considerations

Helical milling is a modern technique in machining processes, yet it is still prone to challenges based on multiple factors.

Understanding these challenges and considerations will help you think whether this process will work for your demands.

Toolpath Programming Challenges

Creating the needed spiral motion for the tool will be done with the help of software that streamlines the process. But any issues that the software encounters will deeply affect the process and the result.

It can result in poor quality products and tool damage.

The solution is to ensure that you develop perfect software that will cover the parameters.

Tool Deflection

Tool deflection is not as complicated as the programming challenges, but it sure affects the quality of the workpiece. It results in inaccurate holes and a low-quality surface finish, and even damages to the tool.

Material Limitations

Helical milling can handle complex projects and hard materials. The constant process of dealing with extra challenging materials like titanium can eventually damage the tool.

Formulating a comprehensive parameter to avoid tool damage will at least help avoid it from happening earlier than expected.

Machine Capability

The success and best results of a process highly depend on the machine’s power and capabilities. Not all machines are created equal. Some can be prone to misalignment that may eventually cause malfunction.

Choosing a machine that can work in a variety of complexities, pressures, and rigidities will assure you of its effectiveness in delivering accurate and quality results without the fear of machine breakdown.

Best Practices for Helical Milling

Helical milling would not be hailed as one of the most popular machining processes if not for its efficiency and high-quality output.

But just like any process, there are some practices to do to take advantage of its benefits.

Optimize Toolpath Parameters

Helical milling requires sets of speed feeds to maximize the tools and the process. Setting up proper parameters on the speed, feed, axial depth, and tool engagement will not only save you from machine or tool dysfunction but also the hassle of not meeting production needs.

Tools & Parts Monitoring

Just like any high-performing machine and tool, ensuring they are at their best always depends on your constant monitoring so you can provide proper cleanup and maintenance so the tools and parts are always back in shape.

Skill Development and Training

While the machines and tools can be at their best with regular checking and maintenance. The team handling the machine and tools, and program itself should be equipped with knowledge and skills in handling complex situations or even proper troubleshooting in case of challenges.

Providing your team with necessary training and development can assure you that everything is in good hands with your competent team.

Helical Milling vs Other Hole Making Methods

| Caraterística | Helical Milling | Perfuração | Aborrecido |

| Acabamento da superfície | Good to Excellent | Moderado | Bom |

| Tool Path | Spiral (helical) | Straight Plunge | Straight with side |

| Tool Wear Rate | Moderate to low

(if optimized) |

Moderado a elevado

(in tough materials) |

Baixa a moderada |

| Chip Evacuation | Manageable (requires air coolant) | Can be difficult in deep holes | Easier

(lower chip volume) |

| Material Suitability | Excellent (good for hard materials) | Varies (struggles with hard materials) | Good (especially in finishing applications) |

Conclusão

Helical milling is a modern and efficient process to create precise holes even on hard materials and challenging applications. With the help of the right parameters and tools, you will surely maximize the flexibility helical milling can offer to help you with your needs.

Here at DEK, we offer expert machining services, including advanced helical milling for high-precision parts. Contact us today to get started on your next project.

FAQs

Where is a helical milling operation commonly used?

Helical milling is generally used in industries that need precise holes, pockets, and entry points, even on hard and delicate materials. Those industries include automotive, aerospace, medical device, mold-making, and manufacturing and prototyping.

What is the purpose of helical gear cutting on milling machine?

Helical gear cutting creates gears with angled teeth, which provide smoother and quieter operation than straight-cut gears.

What is the advantage of using a helical plain milling cutter?

The advantage of a helical plain milling cutter is that it has angled teeth, which engage the material gradually. Because of that, it reduces vibrations and gives smoother cutting and a high-quality service finish compared to straight-tooth cutters.

What are the key features of a helical milling machine?

The key features of a helical milling machine are CNC control, helical toolpaths, rigid construction, and the ability to handle multi-axis movement. Spiral interpolation and high-precision cutting are usually supported by these machines.