Gear Machining Dienst

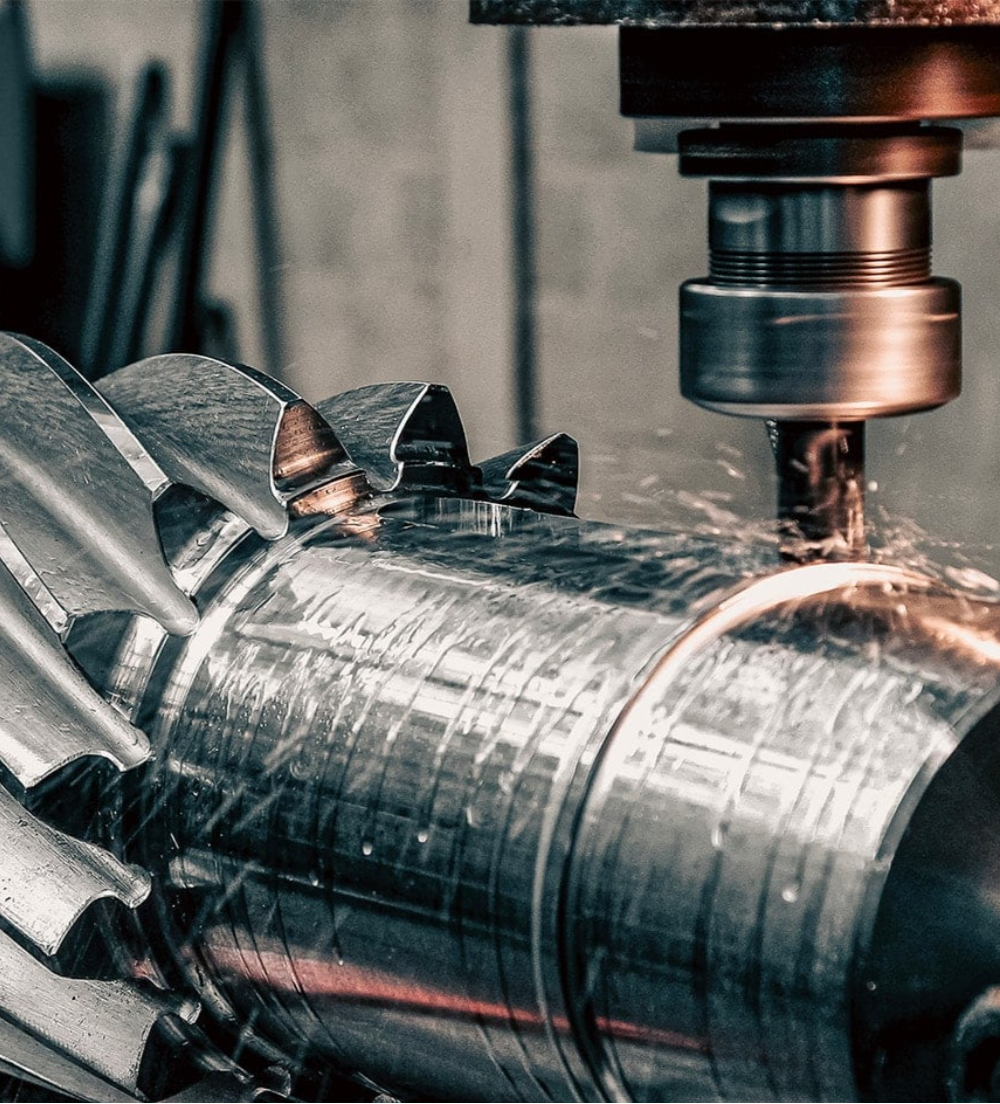

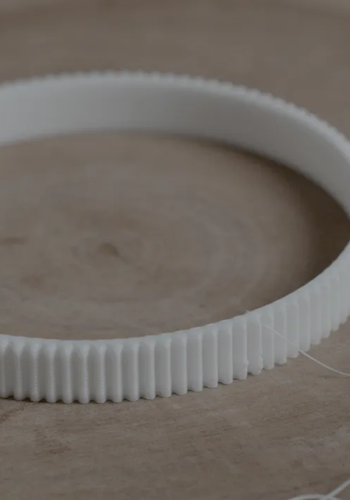

We create precise gears with accurately shaped tooth profiles and dimensions—from small consumer products to large industrial machinery. Our precision makes gears operate smoothly, efficiently, and with minimal noise and vibration.

DEK has a specialized manufacturing technique that uses processes like milling, cutting, hobbing, casting, CNC machining, etc, to produce quality, highly precise gears. We are committed to delivering durable and reliable gear parts that suit your specific project needs. You can count on our unique expertise and technological facilities to deliver complex geometries of gear parts. Whether you require a few order pieces or mass production, we are here to serve.

Einführung

Gear Machining | Highly Specialized, Precise, and Reliable

DEK offers you unparalleled precision and high-quality gear parts. No matter the industry you are in or even if your design is complex with intricate tooth shapes, we have the expertise to meet your requirements.

We have in-house technological gear machining facilities that allow us to deliver quickly and effectively. We also prioritize working with innovative, cutting-edge software and expert professionals. What’s more, we value customer satisfaction and as such we offer you a no minimum order policy.

You can choose from our wide variety of materials available, whether metals or plastic. No matter where you are, you can count on us to deliver.

- End-to-end quality assurance

- Tight tolerance within +/-0.005mm

- Fast turnaround within 4 to 7 days

- Kostengünstige Dienstleistung

- Fähigkeit zur Handhabung komplexer Geometrien

- Custom finishing and surface treatments

Materialien for Gear Machining Service

Metalle

Kunststoffe

Aluminium

Aluminum is a lightweight, corrosion-resistant metal with excellent machinability and a good strength-to-weight ratio. It is commonly used in precision parts where durability and weight savings are both important.

At DEK, we machine aluminum gears for industries needing lightweight but strong components, including aerospace and automotive. Our gear machining service capabilities allow us to produce high-precision gear profiles with clean finishes and consistent quality. We manufacture components like drone gearboxes, aerospace gear systems, EV differential housing, etc, using aluminum.

Legierung

Aluminum 6060, 6061, 6082, 7050, 7075

Messing

Brass is a copper-based alloy known for its excellent machinability, corrosion resistance, heat and electrical conductivity, and low friction. It’s ideal for applications that require quiet, smooth operation and good wear resistance in gears.

We use brass at DEK to create precision-machined gears for electrical devices, instruments, and marine applications. Our machines achieve tight tolerances and smooth finishes that enhance gear performance and reduce noise. You can rely on DEK’s brass gears for consistent quality, long-term durability, and reliable mechanical function.

Legierung

Messing 260, C360, Cz121

Bronze

Bronze is a strong, wear-resistant metal alloy that offers excellent corrosion resistance and low friction. It is widely used for gears operating under heavy loads or in marine environments.

At DEK, we machine bronze gears with exact precision, ensuring optimal fit and durability. Our bronze gears perform well in demanding conditions, offering superior resistance to wear and seizing. With advanced tools and expert handling, DEK delivers bronze gears with smooth finishes and reliable strength for your industrial or marine needs.

Legierung

Bronze 544, 841, 932, 954

Gusseisen

Cast iron is a durable metal with excellent wear resistance, heat retention, and vibration damping. It is frequently used in applications requiring high rigidity and load-bearing capacity.

At DEK, we machine cast iron gears that are ideal for heavy machinery and power transmission. Our gear machining service techniques allow for accurate tooth cutting and fine finishes that reduce vibration and wear. We utilize cast iron to manufacture several gear parts like industrial gearbox housing, automotive differential carriers, CNC machine gears, etc. You can trust DEK’s cast iron gears for long-term performance in rugged, high-load environments.

Rostfreier Stahl

Stainless steel is a corrosion-resistant alloy known for strength, toughness, and durability. It performs well in harsh environments and is widely used in high-precision mechanical applications.

We machine stainless steel gears at DEK for industries such as food processing, marine, and medical. Our parts offer exceptional corrosion resistance and consistent accuracy. With smooth finishes and tight tolerances, DEK’s stainless steel gears deliver top reliability and long-lasting performance in sensitive or corrosive settings.

Legierung

Rostfreier Stahl 301, 303, 321, 304, 304L

Titan

Titanium is a lightweight, corrosion-resistant metal with excellent strength and fatigue resistance. It’s ideal for high-performance applications where weight savings and durability are both essential.

At DEK, we machine titanium gears for aerospace, medical, and defense sectors. Our cutting-edge machines ensure tight tolerances and exceptional surface finishes. You benefit from titanium gears that are lightweight yet incredibly strong, made to meet strict standards, and able to withstand extreme environments with consistent reliability.

Legierung

Titanium Grade 1, 2, 5

Zink

Zinc is a corrosion-resistant, easy-to-machine metal that offers electrical conductivity and recyclability. It’s suitable for producing precise gears in high-volume, low-load applications like electronics and consumer products.

We machine zinc gears at DEK to meet exact specifications and smooth finishes. Ideal for cost-sensitive projects, our zinc gears maintain dimensional accuracy and resist oxidation. With DEK, you get fast turnaround, consistent quality, and dependable gear components for everyday use and moderate mechanical demands.

Legierung

Zamak 3

Nylon

Nylon is a strong, wear-resistant plastic with low friction and excellent fatigue resistance. It performs well in moist environments and is widely used in mechanical gear systems for smooth, silent operation.

At DEK, we machine nylon into durable gears used in automotive parts, conveyors, and consumer products. Our precision tools deliver tight tolerances and clean finishes that reduce noise and vibration. Nylon’s lightweight nature, combined with our expert gear machining service, ensures your parts function smoothly, even in high-cycle applications, with reduced need for lubrication and long service life.

Klassen

Nylon 6, Nylon 6 (30% glasgefüllt), Nylon 6/6 (30% glasgefüllt), Nylon 6 flammhemmend

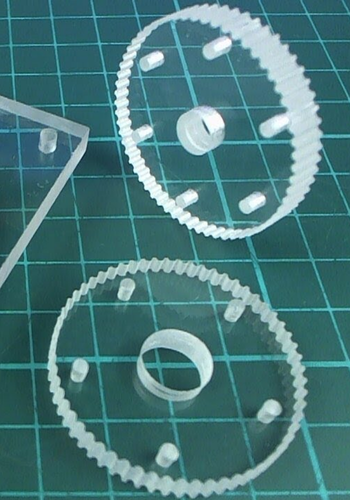

PC

PC is a tough, impact-resistant plastic with high dimensional stability. It maintains strength across a range of temperatures and environments, making it suitable for structural and mechanical parts, including gears.

We machine PC at DEK into transparent or colored gears that need both strength and visual appeal. With our high-precision gear machining service, your PC gears achieve accurate dimensions, clean cuts, and smooth finishes. These parts are ideal for devices that require durable, shatter-resistant gears, especially in electronics or equipment exposed to vibration and frequent use.

PE

PE is a lightweight, chemically resistant plastic with good impact strength and moisture resistance. It offers low friction and performs well in low-load gear applications where quiet operation is key.

DEK uses PE to machine gears for equipment where water resistance and smooth motion are required, such as in pumps or lab tools. Our machining delivers smooth, burr-free finishes and accurate gear profiles. You get PE gears that move quietly, resist chemical corrosion, and reduce maintenance thanks to their wear-resistant, low-friction nature.

PEEK

PEEK is a high-performance plastic with excellent mechanical strength, chemical resistance, and thermal stability. It is ideal for gears used in demanding environments requiring precision and durability.

At DEK, we machine PEEK into high-load and high-temperature gears for aerospace, medical, and industrial applications. Our gear machining service capabilities ensure dimensional accuracy and superior surface finishes. You receive gear components like aerospace sensor gears, MRI-compatible drive gears, chemical pump gears, etc., that withstand extreme conditions without losing performance. PEEK gears from DEK offer long-lasting wear resistance and reliability in the most critical systems.

PMMA

PMMA is a transparent, UV-resistant plastic that offers moderate strength and excellent clarity. It is commonly used in applications requiring visibility and low-load functionality, including display gears and aesthetic gear components.

We machine PMMA gears at DEK for use in instruments, models, and optical systems. Our tools deliver crystal-clear surfaces, precise tooth profiles, and uniform finishes. With DEK, your PMMA gears don’t just look great, but they also operate reliably where light-duty performance and visual appeal are essential. We help bring function and design together in every part.

PP

PP is a lightweight, chemically resistant plastic with good fatigue strength and low moisture absorption. It performs well in wet or chemically aggressive settings with minimal wear.

At DEK, we machine PP into gears used in laboratory devices, chemical processing systems, and light-duty machinery. Our gear machining service ensures precise tooth profiles and smooth finishes for quiet, efficient motion. You can rely on DEK’s PP gears to resist corrosion and retain strength in moist or reactive environments, delivering excellent value and lasting performance.

Klassen

PP Homopolymer, PP+GF(30%)

TPU

TPU is a flexible, abrasion-resistant plastic with good impact strength and elasticity. It’s used in gears that require cushioning, noise reduction, or dynamic movement in mechanical systems.

DEK machines TPU with precision to produce components like medical pump gears, automotive vibration-damping gears, flexible coupling gears, etc. We ensure smooth, flexible gear surfaces that resist wear while maintaining silent operation. TPU gears from DEK combine flexibility and precision, allowing your machines to absorb shocks, reduce vibration, and operate smoothly in fast-moving systems.

Zentrale Anlaufstelle Oberflächenveredelung

Eloxieren

Eloxieren ist ein elektrochemisches Verfahren, das die Korrosionsbeständigkeit, die Haltbarkeit und das Aussehen von Metallen, insbesondere von Aluminium, verbessert.

Perlstrahlen

We can effectively remove rust, paint, scale, and other contaminants from various surfaces using bead […]

PVD-Beschichtung

We offer a wide range of decorative finishes with PVD coating, including various colors and […]

Sofort & Genaue Zitate

Wir verwenden keine automatisierten Online-Kostenvoranschläge, weil sie sehr ungenau sind. Online-Kostenvoranschlagsplattformen stützen sich ausschließlich auf Berechnungen auf der Grundlage von Schnittmengen und festen Koeffizienten und berücksichtigen nicht die tatsächlichen Verarbeitungsnuancen, wie Materialverformung nach der Wärmebehandlung, enge Toleranzanforderungen, Schleifen nach der Wärmebehandlung usw. Folglich können automatische Preisberechnungen zu Ungenauigkeiten führen, die letztlich Ihre Kosten erhöhen.

Aber bei der DEK können Sie beruhigt sein!

Unsere Angebote sind sowohl kosteneffizient als auch präzise, da wir über ein Team professioneller Maschinenbauingenieure verfügen, die jede Zeichnung sorgfältig prüfen. Diese Ingenieure haben mehr als 10 Jahre Erfahrung und verfügen über fundierte Kenntnisse in den Bereichen Programmierung, Maschinenbetrieb, Nachbearbeitung, Materialeigenschaften und mehr. Wir versichern Ihnen, dass Sie innerhalb von 6 Stunden genaue Angebote erhalten.

Unsere Vorteile

2300+ Ingenieure Liebe Arbeit mit uns

Komplexe Geometrien

We can handle helix angles, internal gears, and other challenging profiles. We take your CAD files and bring them to life with high precision, ensuring functionality and reliability in every part. No matter how complex your idea is, we’re ready to make it real.

Zertifizierte Qualität

We follow certified quality standards such as ISO 9001 and maintain strict in-house inspections to ensure every gear meets your expectations. You get full traceability, documentation, and confidence knowing your gears are made with repeatable accuracy and consistent performance.

Oberflächenveredelung

DEK offers a wide range of surface finishing treatments, including anodizing, polishing, black oxide, and passivation. These finishes improve durability, corrosion resistance, and aesthetics.

Hohe Präzision

We use advanced CNC machines and tight process controls to deliver outstanding accuracy in every cut, tooth, and surface. Our high precision guarantees smooth operation and tight tolerances. Your components will always fit and perform perfectly.

Material Vielseitigkeit

DEK works with a wide variety of metals and plastics. You can choose the best material for your specific application, whether it's high strength, lightweight, or corrosion resistance. Our team helps you match the right material to your needs and machines it to perfection.

Schneller Umschwung

We pride ourselves on fast production cycles without sacrificing quality. From prototyping to full-scale production, we streamline our processes to get your gears delivered quickly. You’ll meet tight deadlines, avoid costly delays, and keep your projects on schedule.

Unser Bestellvorgang

RFQ senden

Senden Sie eine Anfrage mit 2D/3D-Zeichnungen und detaillierten Anforderungen per E-Mail oder Online-Formular.

Rezension & Zitat

Unser Ingenieurteam wird jede Zeichnung sorgfältig prüfen und innerhalb von 6 Stunden ein genaues Angebot erstellen.

Bestellung bestätigen

Bestätigen Sie den Kostenvoranschlag, die Einzelheiten und den Lieferplan und unterzeichnen Sie dann den Vertrag.

Produktion

Produktionsprozess organisieren, Programmierung und Bearbeitung starten.

Qualitätskontrolle

Strenge Qualitätskontrolle während der Produktion und der Endkontrolle.

Verpackung und Versand

Verpacken Sie die Teile, bringen Sie Etiketten zur Identifizierung der Teile an, und beginnen Sie mit dem Versand.

RFQ 222 senden

Rezension & Zitat

Bestellung bestätigen

Produktion

QC

Lieferung

FAQ

Gear Machining FAQs zum Kauf

Genaues Angebot einholen Für Ihre nächsten Projekte

Ganz gleich, ob Ihr Projekt kompliziert oder einfach ist, ob es sich um Metall oder Kunststoff handelt, Sie erhalten innerhalb von 6 Stunden ein genaues Angebot.

Heute ein Angebot einholenMehr über Gear Machining

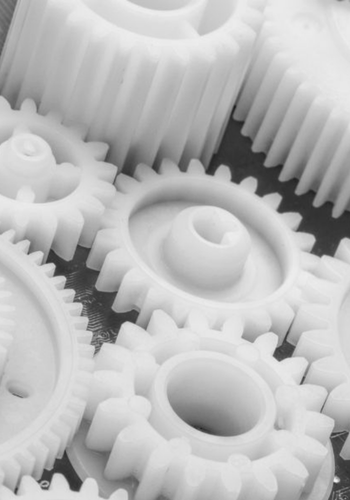

What is Gear Machining?

Gear machining refers to the manufacturing techniques used to create precisely shaped teeth on gears. Gears are toothed wheels that mesh together to transmit rotational motion and power between shafts in mechanical systems. The material is removed from a metal or plastic workpiece using various cutting processes to produce gears with the correct tooth profiles and spacing.

Common gear machining methods include hobbing, where a threaded tool progressively cuts the teeth; shaping, which uses a reciprocating tool; milling with a rotating cutter; and grinding to achieve a smooth final surface finish. These processes are often performed on computer-controlled (CNC) machines for high accuracy and efficiency. The choice of machining technique depends on the gear type, size, material, and required precision level.

What are the Advantages of Gear Machining?

Gear machining offers unmatched precision, material flexibility, and production efficiency. If you need high-quality gears that last, this process gives you the edge. It's ideal for both small and large production volumes, and it handles tight tolerances with ease. You also get better control over surface finish, hardness, and dimensional accuracy.

Here's a breakdown of its key benefits:

- High-dimensional accuracy

- Smooth surface finishes

- Breite Materialkompatibilität

- Ideal for complex shapes

- Suitable for all gear types

- Long-lasting gear performance

- Great for prototyping or mass production

When Do You Use Gear Machining?

You need gear machining services when you require gears that must function with high precision and strength in mechanical systems. Whether you’re building machines for industrial automation, vehicles, medical, or aerospace applications, precise gears are essential to ensure smooth motion, torque transmission, and load-bearing capacity.

You may also need this service if you're developing custom gear solutions that cannot be sourced off the shelf, or when existing gears wear out and require exact replacements. Gear machining is your best option when you need durability, minimal backlash, and tight tolerances that typical manufacturing methods can’t achieve. If your project demands specific gear geometries or specialized materials, gear machining allows full customization. It’s especially valuable when prototyping new designs or scaling production with consistent, high-quality output across every unit.