If you intend to work on a machining project involving precise angled cuts, understanding angular milling is key. This milling technique helps ensure accurate precision and efficiency, and can also help you achieve complex geometries and designs that cannot be done with regular milling.

In this post, you will explore the processes involved, types of angle milling cutters, advantages of angular milling, and so on.

What is Angular Milling?

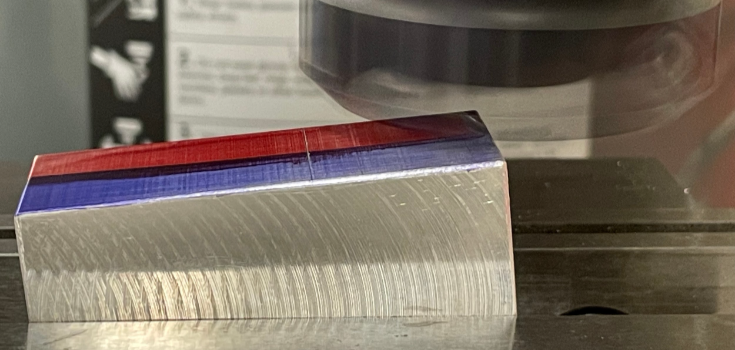

This is a unique milling method used in cutting materials at specific angles, excluding 90 degrees, until a desired design, shape, or geometry is achieved.

This machining technique uses specialized procedures to generate angled features like chamfers, notches, bevelled edges, V-shaped grooves, etc.

Unlike the conventional milling type that is used to create basic flat surfaces, angular milling is suitable for manufacturing complex angled grooves and finishes.

Types of Angle Milling Cutters

Below are two types of angle milling cutters to note.

Single-Angle Milling Cutter

Single-angle milling cutting tools are used for milling operations with one angled face.

They are usually designed as 30, 45, or 60 degrees, although you might find other custom angles depending on your needs. Single-angle cutters are used in chanfragem, bevelling, and machining of one-sided grooves and edges.

Double-Angle Milling Cutter

These are used for complex machining projects involving two angled milling faces. Usually, they have two angled cutting features that enable them to create V-shaped grooves on a workpiece.

They are available in 45, 60, and 90 degrees. Because of the advanced multiple-angled profiles that they possess, they help improve work efficiency and enhance work speed since there’s no need for frequent repositioning and adjustments.

How Does Angular Milling Differ from Regular Milling?

Angular milling is different from the regular or conventional milling technique in the following ways.

Cutting Geometry

Regular milling is usually used to create flat surfaces with the milling tools moving perpendicular or parallel to the workpiece. In angular milling, machining operations are carried out at specific angles to form grooves and edges.

Ferramentas de corte

In a regular milling operation, face mill and end mill tools are used, while in angular machining, unique single and double-angled cutter tools are applied to achieve adequate precision and functionality in the production process.

Aplicações

While regular milling is suitable for machining components with basic features and geometries like slots, blocks, etc, angular milling is suitable for creating parts with detailed precision like chamfers and other intricate angled parts.

Angle Milling Process

Here is a step-by-step process of angular milling you can follow:

Planning and Preparation Process

This is the first step and it involves preparing the materials and cutters, designing drawings and blueprints, and so on.

Here, you will need to decide on the workpiece angle, whether it's 30, 45, or 60 degrees, or if a custom degree is required. Doing this will help you select the accurate cutter.

Beyond that, you need to choose either a single or double cutter based on the project you’re working on. The material of the cutter also matters; for example, carbide can handle many metallic parts with moderate to high tensile strength.

Milling Machine Set Up

At this stage, you will set up the milling machine for the angular machining process. You would need to check if the machine comes with a tilt head feature.

After that, you can use a measuring tool like a dial indicator to see if the tilt is correct and it aligns with the milling requirements.

In situations where the machine doesn’t have a tilt feature, you can generate the angles needed by providing firmly held fixtures like rotary tables to support the milling process.

Once this is done, inspect the machine set-up for firmness and alignment. With this, you can achieve the required precision, enhance tool life, and work efficiently.

Workpiece Set Up

Since the angular machining process generates a lot of vibrations and forces, you should ensure that the workpiece is securely fixed.

Using specialized fixtures or sine vises created for angular milling is vital to ensure a stable workpiece setup. Once the workpiece is secured, you can use a measuring tool to check for alignment again.

Machining of the Angle

The next process is to begin the actual machining operations. Once you start milling the angle, you should begin with stable feed rates and spindle speeds.

This would help you reduce tool chatter and prevent deviations that might affect the finishing and precision level.

You would also need to use coolant to reduce heat buildup. Testing the machining process ahead of time for speed and feeds also helps ensure that you get the correct parameters for the milling operation.

Controlo de qualidade

Lastly, go through a thorough inspection to ensure that the machining outputs meet the desired project requirements.

This involves checking if the precision level, surface finishing, dimensions, tolerances, etc., meet the expected specifications. While final quality control is crucial, inspecting for those parameters during the machining process is good.

Commonly Used Materials for Angle Milling

Many metallic materials are used in angular milling operations. Each of them has its own properties that make it compatible with such a machining process. Below are some of the materials and the parameters to know about them.

| Material | Dureza | Resistência à tração | Machinability (% of B1112) | Aplicações |

| Steel (Carbon and Alloy) | 120-250 | 400-1500 | 50-70% | Essential in structural engineering, machining parts and components. |

| Aço inoxidável | 150-600 | 480-2000 | 40-50% | Used in creating medical equipment and food processing components. |

| Ligas de alumínio | 25-150 | 90-570 | 150-300% | Vital in designing aerospace and automotive parts and electronic components. |

| Latão | 55-100 | 200-550 | 100-150% | Used in creating aesthetic equipment, plumbing parts, and musical instruments. |

| Titanium Alloys | 180-420 | 650-1400 | 20-30% | Important in making aerospace and automotive parts and biomedical equipment. |

| Cobre | 35-110 | 200-400 | 20-100% | Essential in producing electrical and plumbing parts. |

| Ligas de níquel | 150-500 | 600-1400 | 10-40% | Used in manufacturing chemical processing equipment and marine engineering components. |

Advantages of Angular Milling

Here are some of the benefits of angular milling operations:

Enhanced Efficiency

Angular machining allows multiple angled features to be generated on a workpiece just in a single operation. This way, you can maximize time and labor while also getting more output.

Alta precisão

With angular milling, you can get components with adequate precision. The milling methods help ensure that the necessary angles are reached during manufacturing, thereby eliminating deviations while generating parts that meet required specifications and functions.

This makes it valuable in creating aerospace, medical, and sports components.

Cost Effective

You can also effectively maximize material usage with this technique. In angular milling, only the necessary parts are worked on, thereby preventing material wastage.

Perfect Surface Finish

Angular milling gives a smooth finishing touch. With this, you don’t need a final finishing process and can, therefore, save more time, labour, and cost.

Improved Designs and Functions

Without angular milling, creating some components would not be possible. Complex and intricate geometries are designed using this technique.

With this, it becomes easier to generate parts with specific features, aesthetics, functions, and so on, thereby leading to more customer satisfaction.

Limitations of Angle Milling

Set Up Complexity

Setting up an angular milling cutter together with the workpiece and machine takes more time and expertise. Moreover, you must align the setup properly for it to work. Without this, there are more chances for errors, which will cost you more time and effort.

Desgaste da ferramenta

Tool wearout occurs more in this technique because of the angled surfaces. The cutting tools constantly work on the material at specific angles, leading to the wear out of the tool. With this, you will need to replace the cutter more often.

Machine Requirement

Many of the regular milling machines are not suitable for angular milling. To be able to carry out angular machining, you might need to invest in advanced CNC machines.

Common Applications of Angular Milling

Chamfering and Bevelling: Valuable in creating chamfers, preventing components from edge damage, and enhancing fitment.

V-groove Milling: Useful in generating V-shaped grooves in machining components and decorative parts.

Thread Milling: Important in generating threads on screws, bolts and other fasteners.

Dovetail Slot Creation: Useful in machinery and structural engineering to design interlocking joints and dovetail slides.

Serration and Knurling: Used in creating features to enhance fastening or gripping.

Tapered Surface Machining: Valuable in designing shafts, pins, etc, which are useful in structural engineering.

Complex Angular Components: Used in designing aerospace parts like turbine blades that need adequate angle precision.

Fixture and Tooling Parts: Important in making jigs and fixtures used as support in the manufacturing process.

Helical Milling: Used in creating spiral and helical grooves in drills, cutting tools, etc.

Angular Slots: Valuable in creating slots in mechanical and structural components.

Tips for Angular Milling

Angular milling, as an advanced machining technique, requires some skills and expertise to carry out. The tips below will help in your next machining operations.

Select the Most Suitable Cutter

Depending on the components you want to create, you need to consider the type of cutter to use.

For basic angled machining operations like the creation of bevels and chamfers, single-angled cutters are good. However, for more advanced milling like V grooves, double-angled cutters are suitable.

Also, when working on tough materials like aço, carbide-coated cutters are the best since they can withstand extreme heat.

Create a Cooling Mechanism

When carrying out an angular milling operation, you should expect some heat generation. This can be managed by using a suitable coolant based on the materials you’re working with.

For hard materials like steel, use oil-water-based coolant. Less hard materials like aluminum only need mist coolants.

Test Milling Parameters

Testing milling parameters like speed and feed helps you determine the best balancing position for your machining operation.

This, in turn, helps you eliminate errors, improve precision and efficiency, and enhance tool lifetime. Usually, softer materials withstand high speed than harder ones.

Combine Cutters when Necessary

For more efficiency, you might need to combine cutters. For example, when milling a V groove, combining an end mill and an angled cutter will allow you to complete the operation without replacing tools.

Measure Angles and Inspect Surface Finishes

While angular milling ensures precision, you might also want to check the measured angles using an instrument like an angle gauge. Also, look out for the final finishing, if it’s smooth enough or needs improvements.

Provide Support for Holding Material

An angular machining set-up should be as rigid as possible. This milling technique causes a lot of vibration and tool breakage when care is not taken. So, you must provide custom rigid angular support to hold the workpiece while machining.

Conclusão

Angular milling remains a valuable technique for creating various angled industrial parts. With it, you can achieve components with consistent precision, finishing, aesthetics, and designs.

Em DEK, we value accuracy and efficiency in our machining process. Over the years, we’ve equipped our workshop with sophisticated modern machines that meet every project's needs. Whether your project involves angular milling, CNC machining, or other procedures, we have the best team for the job.