If you work with waterjet cutting, you know how important the nozzle is. It directs the high-pressure water stream to cut through materials accurately. Choosing the right nozzle affects cutting speed, precision, and durability.

In this guide, we’ll explain everything you need to know about waterjet cutting nozzles.

What are Waterjet Cutting Nozzles?

A waterjet nozzle is the part of a waterjet machine that directs the water stream to cut a material. It is also called a focusing tube or mixing tube. The nozzle is very strong because it needs to handle high-pressure water.

Over time, the nozzle wears out due to the pressure, so you need to replace it regularly.

What is the Purpose of the Water Jet Nozzle?

The main job of the waterjet nozzle is to focus the water stream for precise cutting. The size of the water stream depends on the material and its thickness.

Inside the nozzle, there is a jewel orifice, which controls the water flow. This helps the nozzle last longer and improves cutting accuracy.

Key Components of a Waterjet Cutting Nozzle

Waterjet nozzles have three main parts: the jewel orifice, the mixing tube, and the focusing tube. Each part helps the waterjet cut materials accurately and efficiently.

The jewel orifice, usually made of sapphire or diamond, pushes high-pressure water into the mixing tube. Here, the water mixes with abrasive materials. Then, the mixture moves through the focusing tube to make precise cuts.

Using high-quality parts makes the nozzle last longer and work better over time.

How Waterjet Nozzles Work?

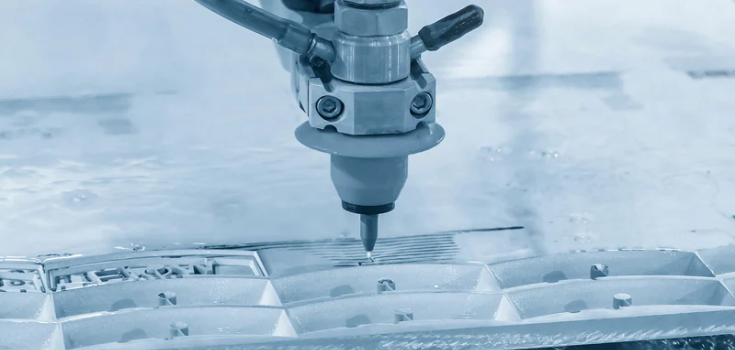

Waterjet cutting nozzles convert high-pressure water into a fast-moving stream. When mixed with abrasives, this stream can cut through tough materials like metal and ceramics. This makes water jet operation useful for many industrial and manufacturing applications.

The nozzle controls the speed and precision of the cut. A smaller nozzle creates detailed cuts, while a larger one increases cutting speed for bigger projects. It also focuses the water stream, turning pressure into cutting power

Waterjets can cut almost any material, including glass, marble, wood, and even food. They can drill titanium, make fine details in stone and metal, and sterilize liquids. Each material and thickness requires the right nozzle size to get the best results.

Types Of Waterjet Cutting Nozzles

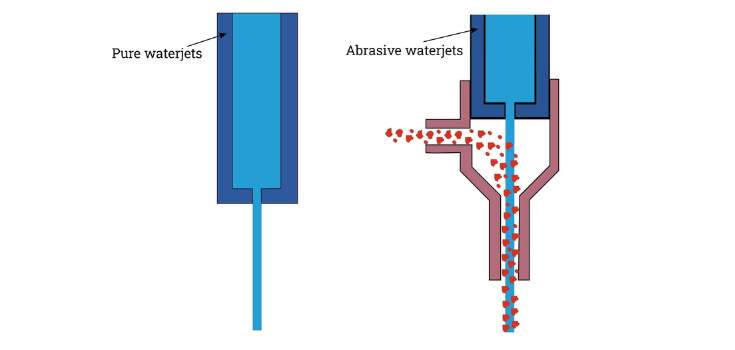

Here are the two types of waterjet nozzles:

1. Pure Waterjet Nozzles

- Uses only water (no abrasives).

- Cuts soft materials like paper, foam, rubber, textiles, cardboard, and plastics.

- Has a very small opening because no abrasive particles are used.

2. Abrasive Waterjet Nozzles

- Uses water and abrasive particles to cut harder materials.

- Has a special mixing chamber where abrasive particles are added to the water.

- The high-pressure water speeds up the abrasive particles to cut materials like metal, ceramics, stone, glass, and composites.

Specifications of a Water Jet Nozzle

A water jet nozzle has different features that affect how it works. Here are the main things you need to know:

Orifice Diameter

The orifice diameter is the size of the hole in the nozzle where water comes out. A smaller hole creates a stronger water jet but also wears out the nozzle faster. The diameter of the water jet cutting nozzle is usually three times the orifice diameter. A small orifice helps with accuracy, but if it is too small, it slows down cutting and wears out quickly.

Flow Rate

The flow rate is how much water passes through the nozzle in a certain time. It is measured in liters per minute (LPM) or gallons per minute (GPM). A higher flow rate makes cutting faster but also causes more wear on the nozzle.

Nozzle Size

The nozzle size is the width of the bore hole, usually three times the orifice diameter. There are three types of nozzle sizes. Small nozzles, which range from 0.254 mm to 1.016 mm (0.01 in to 0.04 in), are used for precise and detailed cutting.

Medium nozzles, which range from 1.016 mm to 2.032 mm (0.04 in to 0.08 in), are used for general cutting where high accuracy is not needed. Large nozzles, which range from 2.032 mm to 6.35 mm (0.08 in to 0.25 in), are used for fast cutting of large materials.

Pressure Rating

The pressure rating tells you the highest amount of water pressure a nozzle can handle properly. If the pressure goes beyond this limit, the nozzle can get damaged or even break. Different nozzles have different pressure ratings, and manufacturers provide this information when you buy a replacement nozzle.

A modern waterjet cutting nozzle can reach pressures as high as 90,000 psi. But at such high pressure, the nozzle and other parts wear out quickly. The best pressure for long-lasting performance is between 40,000 psi and 60,000 psi.

Material Used For Making Waterjet Nozzles

Waterjet nozzles come in different materials, depending on how long they need to last, how much pressure they can handle, and their cost. Here are the most common materials:

Carboneto de tungsténio

Carboneto de tungsténio is the most popular choice. It is very strong—almost as hard as diamond. These nozzles work well under very high pressure (up to 90,000 psi). If you use them properly, they can last over 200 hours. If used roughly, they may need to be replaced after 100 hours.

Diamante

Diamond nozzles are the hardest and most durable. They can handle extreme pressure and cut the toughest materials. These nozzles can last up to 1,000 hours. However, they are the most expensive, costing about 20 times more than sapphire nozzles. If you do a lot of heavy cutting, diamond nozzles may be the best choice.

Sapphire

Sapphire nozzles are strong and affordable. They do not react with chemicals. However, they have a shorter lifespan, usually between 50 to 100 hours. They can handle water pressures between 60,000 and 70,000 psi. Ruby nozzles are very similar to sapphire nozzles.

Cerâmica

Ceramic nozzles are a newer option. They can be even stronger than hardened steel and are resistant to rust and corrosion. Their lifespan depends on the type of ceramic used.

What Materials Can a Waterjet Nozzle Cut?

A waterjet nozzle can cut almost any material. Here are some common ones:

Metais: You can cut even the hardest metals, like hardened steel. For a smooth and fast cut, you’ll need an abrasive jet nozzle.

Plásticos: You can cut any plastic without melting it. Most plastics need an abrasive jet nozzle.

Cerâmica: Waterjets are often used to cut ceramic tiles and stone. Depending on the ceramic type, you may use either an abrasive or a pure waterjet nozzle.

Rubber: A pure waterjet nozzle at low pressure is perfect for cutting rubber. This method is cost-effective.

Glass: You can cut glass for art, construction, and decoration. An abrasive jet nozzle can even cut bulletproof glass.

Thin Films: You can cut thin foils, like aluminum foil, using a pure waterjet nozzle. Even thin metal foils can be cut this way.

Foam: Waterjet cutting gives clean cuts on foam without burn marks. A pure waterjet nozzle works well and is affordable.

Wood: Soft or thin wood can be cut with a pure waterjet nozzle. For thick or hardwood, you’ll need an abrasive jet nozzle.

Nozzle Connection Type

When choosing a waterjet cutting nozzle, you have different ways to connect it. Here are three common types:

Threaded Nozzles

Threaded nozzles have screw-like threads on the ends. You need special tools to attach and remove them, but they provide a very secure fit. These nozzles can handle extremely high pressure without leaking. Once properly installed, you don’t have to worry about them disconnecting by accident.

Quick-Connect Screw Nozzles

Quick-connect screw nozzles are a mix of snap and threaded nozzles. They have a locking system like snap nozzles but also require some screwing to secure them in place. This makes them more reliable than snap nozzles, as they are less likely to disconnect accidentally. At the same time, they are still easier to use than fully threaded nozzles.

Quick-Connect Snap Nozzles

Quick-connect snap nozzles, also called quick-disconnect nozzles, do not require any tools to attach or remove. They use a snap-lock system to stay in place, and they are very easy to use. However, they are not as strong as threaded nozzles and may not handle very high pressure. In some cases, the locking mechanism can accidentally release during operation.

How to Choose the Right Waterjet Nozzle?

Choosing the right waterjet nozzle depends on a few key factors:

- Think about what you need the nozzle for. Some jobs limit your options. For high pressure, avoid snap connection nozzles.

- Nozzles wear out at different rates. If using abrasives, pick a tough material. Diamond lasts the longest but costs more. Tungsten carbide is a solid, common choice.

- The hole size affects cutting. There’s no one-size-fits-all, so check the manufacturer’s guide or test different sizes.

- Choose a nozzle that can handle more pressure than your system uses for safety and durability.

- Use a machinability chart to match the right nozzle to your material. This improves cutting and extends nozzle life.

Applications of Waterjet Cutting Nozzles

Here are some key areas where you might see them in action:

Indústria aeroespacial

If you’re working in aerospace, you need precise cuts for strong but lightweight materials like titanium, aluminum, and composites. Waterjet nozzles help you create complex parts, such as aircraft panels and engine components, without weakening them.

Indústria automóvel

In the automotive world, waterjet nozzles let you cut metal, rubber, and composite materials quickly and accurately. Whether you’re making engine parts, car body pieces, or custom modifications, waterjet cutting is a great way to get clean, precise results.

Indústria eletrónica

If you work with electronics, you know how delicate materials like circuit boards and semiconductor wafers can be. Waterjet nozzles allow you to cut these fragile components without causing damage. They also help in making connectors, housings, and other small electronic parts with tight tolerances.

Medical Devices Industry

Waterjet cutting is essential for making medical devices like surgical tools, implants, and diagnostic equipment. Since it can cut materials like stainless steel, titanium, and ceramics without heat, you don’t have to worry about damaging delicate medical parts.

Effects of Water Quality on Nozzle Lifespan

The quality of water you use directly affects how well your waterjet nozzles work and how long they last. Dirty water with impurities can wear down the nozzles, so it can make the cutting process less effective. Using clean, high-quality water helps keep your nozzles working properly for a longer time.

Filtering your water or using a water treatment system can greatly reduce the damage caused by impurities, helping your nozzles last longer. Paying attention to water quality ensures your cutting system works consistently and reliably. By taking care of the water you use, you improve the efficiency and performance of your waterjet cutting.

Tools for Monitoring Nozzle Lifespan

To keep your waterjet cutting nozzles working well and lasting longer, you need to check their condition regularly. There are several tools that help you catch problems early, saving you time and money on unnecessary repairs.

Here are some useful tools for monitoring nozzle performance:

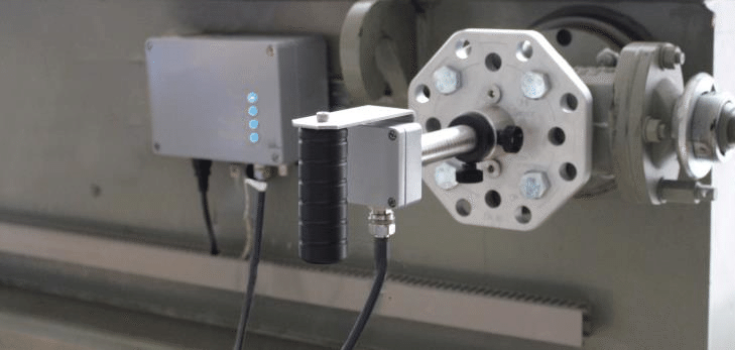

Wear Monitoring Sensors

Wear monitoring sensors track changes in the nozzle’s size or performance over time. They provide real-time data, helping you detect early signs of damage. By catching these issues early, you can schedule maintenance before the nozzle fails, reducing unexpected downtime.

Laser Alignment Systems

Laser alignment systems make sure the nozzle is positioned correctly. Proper alignment ensures clean, precise cuts and even wear on the nozzle. If the nozzle is misaligned, it can cause uneven cutting and wear out faster. Using a laser alignment tool regularly helps maintain accuracy and extend nozzle life.

Pressure Gauges

Pressure gauges measure the water pressure in the system. Keeping the pressure steady ensures the nozzle works properly. If the pressure suddenly drops or spikes, it could mean the nozzle is wearing out or getting clogged. Monitoring pressure helps you spot issues before they affect cutting quality.

Inspection Cameras

Inspection cameras let you take a close look at the nozzle without taking the system apart. You can check for cracks, wear, or erosion quickly and easily. Regular inspections with a camera help you catch problems early and keep your nozzles in good shape.

Flow Rate Meters

Flow rate meters check how much water and abrasive material are moving through the nozzle. If the flow rate changes, it could mean there’s a clog or the nozzle is wearing down. These meters help ensure smooth operation and prevent buildup inside the nozzle.

Common Problems of Waterjet Cutting Nozzles

Waterjet cutting nozzles are tough, but they can develop problems over time. Knowing what to watch for and fixing issues early will keep your cuts clean and your nozzle working longer. Here are some common problems and how to solve them:

Clogging Issues

Dirt, abrasive particles, or leftover materials can clog the nozzle, blocking water flow and making cuts less precise.

Clean the nozzle regularly with high-pressure air or water. Use a good filtration system to prevent clogs in the first place.

Sobreaquecimento

Running the system too long without breaks, using too much pressure, or poor maintenance can cause the nozzle to overheat, reducing efficiency.

Keep the system well-ventilated. Take breaks during long cuts and monitor pressure levels to avoid overheating.

Uneven Cuts

If your cuts look rough or uneven, the nozzle might be misaligned, parts may be worn out, or the water and abrasive flow may be inconsistent.

Check that the nozzle is aligned correctly. Make sure water pressure and abrasive flow are steady. Replace worn parts like focusing tubes or orifices when needed.

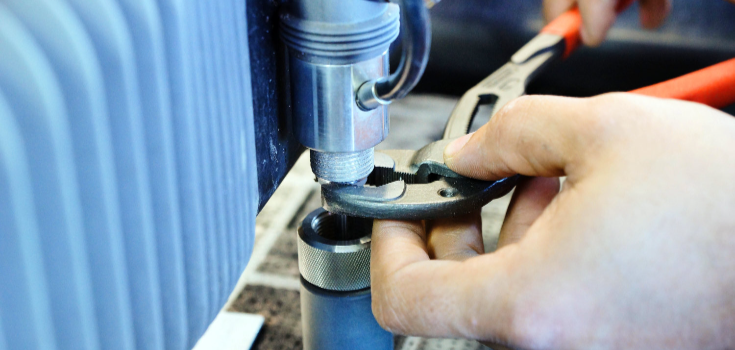

Leaks

Leaks can happen at connection points due to worn-out seals or damage, reducing cutting power and wasting water.

Check the nozzle and fittings for wear or loose connections. Tighten or replace seals as needed.

Excessive Wear

Nozzles wear down over time from constant high-pressure water and abrasives. This can make your cuts less accurate.

Inspect your nozzle often and replace worn-out parts. Use high-quality abrasives and adjust pressure settings to slow down wear.

Conclusão

Keeping your waterjet cutting nozzles in top condition is important to achieving precise, high-quality cuts. By choosing the right nozzle, monitoring wear, and maintaining clean water, you can extend the lifespan of your equipment and improve efficiency.

Em DEK, we manufacture precision components using advanced waterjet cutting machines. If you need high-quality nozzles or custom-cut parts, contact us today to see how we can support your production needs!

FAQs

How are waterjet cutting nozzles made?

Waterjet cutting nozzles are made from tungsten carbide, a hard but brittle material. They are formed by pressing powdered tungsten carbide into a mold and heating it under high pressure.

What is a water jet cutting nozzle’s diameter?

The size of a water jet cutting nozzle depends on the type of cutting you’re doing. For abrasive waterjet cutting, the water stream is round and usually between 0.030” and 0.040” (0.76 mm and 1.02 mm) wide. Because of its round shape, it’s hard to cut perfectly square inner corners—the jet will always leave a small curve.

How long does a waterjet nozzle last?

You should replace your waterjet nozzle after 40 to 1000 hours of use. The lifespan depends on what you’re cutting, water pressure, abrasive quality, and nozzle material. Check it regularly to catch wear early and keep your cuts precise.

What is the cost of waterjet cutting nozzles?

Waterjet cutting nozzles cost between $20 and $400+, but the price doesn’t always mean better value. A $400 diamond nozzle may save you money by lasting longer than a $20 sapphire one. Tungsten carbide nozzles ($50-$100) offer a good balance of cost and durability.

How do you know when it’s time to get a new waterjet nozzle?

Replace your nozzle if cutting is less precise, abrasive use increases, or the machine slows down. Check for wear regularly to avoid downtime and keep your waterjet running smoothly.

What factors describe the lifespan of waterjet cutting nozzles?

Your waterjet nozzle lasts longer if you use clean water, high-quality abrasives, and the right cutting pressure. Heavy use wears it out faster. To extend its life, maintain proper pressure, use good abrasives, and follow best practices.